The Importance of Stainless Steel Square Pipe Polishing Machines

Stainless steel has become an indispensable material in various industries, thanks to its strength, durability, and corrosion resistance. Among the various forms of stainless steel components, square pipes are particularly prominent due to their versatility and aesthetic appeal. However, to enhance their appearance and functionality, these square pipes often require a polishing process. This is where stainless steel square pipe polishing machines come into play, offering efficient and high-quality solutions for manufacturers and fabricators.

What is a Stainless Steel Square Pipe Polishing Machine?

A stainless steel square pipe polishing machine is a specialized industrial tool designed to finish the surfaces of square pipes made from stainless steel. These machines come equipped with various features that allow users to achieve precise and consistent polishing results. The primary goal of polishing is to remove surface imperfections, such as scratches, stains, and oxidation, while also enhancing the metal's reflective properties. This process not only improves the aesthetics of the pipes but also helps in prolonging their lifespan by providing a smoother surface that is less prone to rust and corrosion.

Types of Polishing Machines

There are generally two types of polishing machines for stainless steel square pipes manual and automated. Manual polishing machines are often more budget-friendly and suitable for smaller operations where only a limited number of pipes need polishing. These machines require operators to apply the polishing compound and manually guide the pipes through the polishing process.

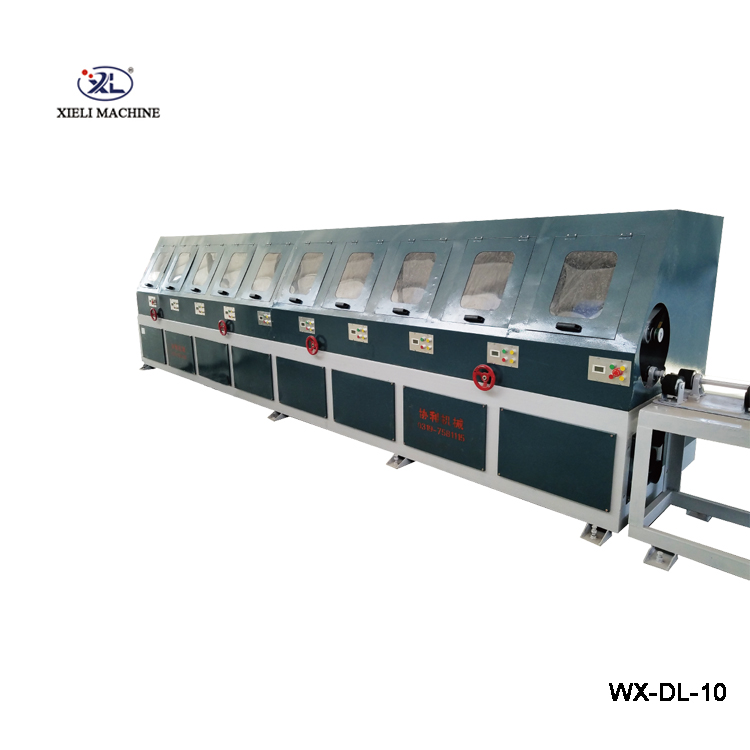

Conversely, automated polishing machines are designed for large-scale operations. These machines can handle multiple square pipes simultaneously and require minimal human intervention once set up. Features such as conveyor belts and adjustable polishing heads allow for a highly efficient process, saving time and labor costs while maintaining a consistent finish on every piece.

stainless steel square pipe polishing machine products

Benefits of Using Polishing Machines

1. Improved Surface Finish Polishing machines can significantly improve the surface finish of stainless steel square pipes, providing a sleek, shiny appearance that is aesthetically pleasing. This is crucial for applications where appearance is important, such as in architectural design and high-end consumer products.

2. Increased Longevity By eliminating surface imperfections and providing a smooth finish, polishing machines help in extending the life of stainless steel pipes. A polished surface is less likely to accumulate dirt, contaminants, or moisture, which can lead to corrosion over time.

3. Efficiency and Productivity Automated polishing machines especially increase productivity, allowing manufacturers to process a higher volume of pipes in less time. This efficiency directly translates to greater profitability and a competitive edge in the market.

4. Customization Options Many modern polishing machines come with customizable settings, allowing users to adjust the speed, pressure, and type of polishing compound used. This flexibility means that operators can achieve the desired finish for a variety of applications.

Conclusion

In conclusion, stainless steel square pipe polishing machines play a crucial role in enhancing the quality and longevity of stainless steel products. As industries continue to innovate and demand higher standards of material finishes, the importance of efficient and effective polishing solutions cannot be overstated. Investing in state-of-the-art polishing machines not only boosts production capabilities but also establishes a manufacturer’s reputation for quality, making it an essential consideration for any business involved in the fabrication of stainless steel components. As technology advances, we can expect even more sophisticated polishing systems that meet the ever-growing demands of the industry.