The Evolution and Significance of Stainless Steel Square Pipe Polishing Machines

In the realm of metal fabrication, stainless steel has emerged as a preferred material due to its corrosion resistance, durability, and aesthetic appeal. Among the various forms stainless steel takes, square pipes are particularly valued for their structural integrity and versatility in diverse applications, from construction to automotive and beyond. To enhance the visual appeal and surface quality of these stainless steel square pipes, the polishing process plays a crucial role. As a result, the demand for advanced polishing machines has surged, prompting the establishment of specialized polishing machine factories worldwide.

The Importance of Polishing Stainless Steel Square Pipes

Polishing is not merely an aesthetic enhancement; it significantly impacts the functionality and longevity of stainless steel products. A polished surface reduces roughness, thereby minimizing the accumulation of contaminants and enhancing the ease of cleaning. This is particularly vital in industries such as food processing and pharmaceuticals, where hygiene is paramount. Furthermore, a smooth finish helps to prevent stress corrosion cracking, which can compromise the structural integrity of pipes over time.

Technologies in Polishing Machines

Stainless steel square pipe polishing machines have evolved considerably over the years. Modern factories employ advanced technologies to improve efficiency and output quality. Key innovations include

1. CNC Technology Computer Numerical Control (CNC) systems allow for precise control over the machining process. This technology enables manufacturers to achieve consistent surface finishes across large production runs, reducing labor costs and minimizing errors.

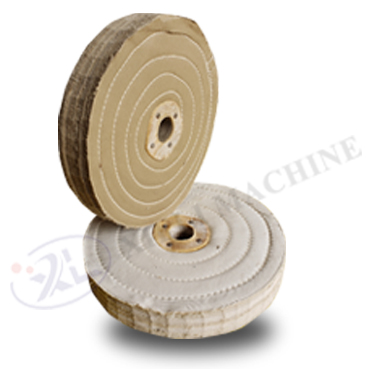

2. Multi-Head Machines These machines can polish multiple pipes simultaneously, significantly increasing throughput. By utilizing a series of polishing heads with varying grits, manufacturers can achieve a range of finishes from a brushed look to a mirror finish in one pass.

3. Automated Systems Automation in polishing machinery leads to less manual intervention, reducing the risk of human errors. Automated feeding systems ensure that pipes are processed in a streamlined fashion, further enhancing operational efficiency.

stainless steel square pipe polishing machine factories

4. Eco-Friendly Solutions With increasing environmental awareness, polishing machine factories are also focusing on creating machines that consume less energy and produce fewer waste products. Several modern polishing machines utilize closed-loop systems to recycle polishing compounds, thereby minimizing environmental impact.

The Global Landscape of Polishing Machine Factories

The establishment of stainless steel square pipe polishing machine factories has not only catered to growing market demands but has also ignited a competitive landscape. Countries known for their manufacturing prowess, such as Germany, Italy, and China, have become hubs for the production of these specialized machines. These factories are known for their robust engineering, innovative designs, and adherence to international quality standards.

Moreover, the global nature of supply chains allows for the distribution of these advanced machines across various markets. Factories in developing regions are increasingly acquiring state-of-the-art polishing technologies, thus enhancing their manufacturing capabilities and contributing to local economies.

Challenges and Prospects

Despite the promising trends, polishing machine factories face several challenges. The fluctuating prices of raw materials and rising labor costs can strain profit margins. Additionally, the rapid pace of technological advancements necessitates continuous investment in research and development to stay competitive.

However, prospects remain bright for the polishing machine industry. With the increasing demand for high-quality stainless steel products in construction, automotive, and even consumer goods, the future is robust. As industries continue to prioritize quality and efficiency, the role of polishing machine factories will be more crucial than ever.

Conclusion

Stainless steel square pipe polishing machines are pivotal in ensuring the quality and longevity of stainless steel products. As technology advances and markets evolve, the factories producing these machines must adapt and innovate to meet the demands of a dynamic industry. The significance of polishing in enhancing both the aesthetic and functional characteristics of stainless steel cannot be overstated, marking polishing machine factories as vital players in the global manufacturing landscape. As we look ahead, investing in advanced polishing technologies will undoubtedly shape the future of stainless steel fabrication, contributing to advancements across various sectors.