The Importance of Stainless Steel Square Pipe Polishing Machines

In the realm of metalworking, stainless steel has become a favored material due to its resistance to corrosion, durability, and aesthetic appeal. Among the various forms of stainless steel, square pipes are especially notable for their versatility in applications ranging from construction to automotive parts. However, the appeal of these pipes often hinges not just on their structural properties, but also on their surface finish. This is where stainless steel square pipe polishing machines come into play, revolutionizing the way these essential components are prepared for market.

Understanding the Polishing Process

Polishing is a crucial step in the manufacturing of stainless steel square pipes. The process not only enhances the visual appeal of the pipe but also improves its surface smoothness, which can influence its performance in specific applications. The polished surface is less likely to harbor dirt and bacteria, making it easier to clean and maintain, which is particularly important in industries such as food processing, healthcare, and pharmaceuticals.

Modern polishing machines are designed to achieve a high level of finish and consistency across all manufactured pieces. They operate using advanced technology that automates much of the polishing process, from initial grinding to buffing and finishing. This automation leads to greater efficiency and reduces the risk of human error, ensuring that every square pipe meets the high standards required by various industries.

Types of Polishing Machines

There are several types of polishing machines used in the processing of stainless steel square pipes. Each type has its unique advantages tailored to different production needs

1. Mechanical Polishers These machines utilize abrasive wheels to mechanically smooth the surface of the stainless steel. They are effective for heavy-duty polishing and can achieve a highly polished finish.

2. Chemical Polishers These employ a chemical solution to remove surface imperfections and oxidation, resulting in a shiny appearance. While not as common for square pipes, they can be advantageous for smaller parts or complex geometries.

3. Electrolytic Polishers Using electrochemical reactions, these machines can produce an exceptionally smooth and reflective surface finish. They are particularly useful for stainless steel, as they enhance the material's corrosion resistance.

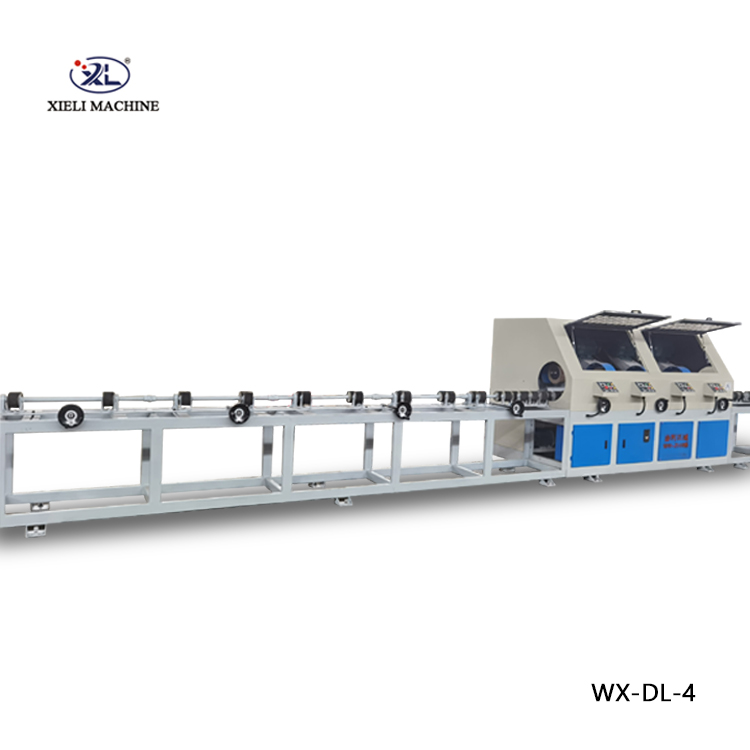

stainless steel square pipe polishing machine

4. Robotic Polishing Systems Automation has taken polishing to a new level, with robotic systems able to handle multiple tasks with precision and consistency. These systems are ideal for large-scale manufacturing where uniformity and efficiency are paramount.

Benefits of Using Polishing Machines

Investing in stainless steel square pipe polishing machines offers numerous benefits that can enhance both product quality and production efficiency

- Improved Aesthetic Appeal A polished finish enhances the appearance of stainless steel pipes, making them more attractive to consumers and businesses.

- Increased Corrosion Resistance Polished surfaces are less prone to corrosion due to the removal of micro-imperfections that can trap moisture and cause rust.

- Enhanced Durability A smooth surface reduces wear and tear, leading to longer-lasting products.

- Time and Cost Efficiency Automated polishing machines can process large volumes of pipe in a fraction of the time it takes manual polishing, ultimately reducing labor costs and production times.

- Versatility Polishing machines can be adjusted to accommodate various sizes and thicknesses of square pipes, making them adaptable to different production requirements.

Conclusion

As industries increasingly prioritize quality and durability, the demand for well-finished stainless steel square pipes continues to rise. Polishing machines play a vital role in meeting this demand by ensuring that pipes not only fulfill functional requirements but also possess the aesthetic quality that consumers expect. By investing in advanced polishing technology, manufacturers can enhance their competitive edge, improve product quality, and ultimately contribute to better end products across a myriad of applications. Thus, stainless steel square pipe polishing machines are not just equipment; they are essential tools for success in the modern metalworking landscape.