Stainless Steel Pipe Polishing Machine Suppliers A Comprehensive Overview

In today's industrial landscape, the demand for high-quality, aesthetically pleasing stainless steel products has soared. One crucial aspect of manufacturing stainless steel pipes is the polishing process, which enhances both appearance and corrosion resistance. Consequently, the role of stainless steel pipe polishing machine suppliers has become increasingly significant. This article delves into the characteristics, functionalities, and selection criteria for choosing the right polishing machine supplier.

The Importance of Polishing in Stainless Steel Pipe Production

Polishing stainless steel pipes is essential for several reasons. Firstly, a smooth surface finish is critical to maintaining hygiene standards in industries such as food and beverage, pharmaceuticals, and healthcare. A well-polished pipe minimizes the risk of bacterial growth and corrosion, thus ensuring product quality and safety.

Secondly, polished stainless steel pipes are more visually appealing, making them a preferred choice for architectural applications and visible components in various engineering projects. Customers often choose products based on aesthetics, where a high-gloss finish can enhance a company’s brand image.

Features of Stainless Steel Pipe Polishing Machines

Stainless steel pipe polishing machines are designed with various features and capabilities that can significantly impact the efficiency of the polishing process. Some of the key features to consider include

1. Automation Modern polishing machines often incorporate automation technology, allowing for consistent and efficient polishing without the need for manual intervention. Automated machines can adjust speed and pressure dynamically, ensuring uniform results.

2. Versatility A good polishing machine should accommodate different pipe sizes and grades of stainless steel. Versatile machines can handle various applications, reducing the need for multiple pieces of equipment.

3. Surface Finish Quality The primary goal of polishing machines is to achieve a specific surface finish. Suppliers should offer machines capable of achieving a range of finishes (e.g., satin, mirror) to meet the diverse requirements of clients.

4. Ease of Use Intuitive controls and user-friendly interfaces can significantly reduce training time and improve the productivity of the operators.

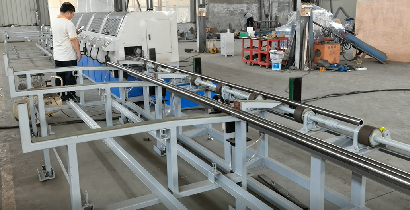

stainless steel pipe polishing machine supplier

5. Durability and Maintenance Stainless steel polishing machines should be built to withstand rigorous industrial use. Suppliers offering machines with easy maintenance features often result in reduced downtime and lower operational costs over time.

Choosing the Right Supplier

When it comes to selecting a stainless steel pipe polishing machine supplier, several factors need to be considered

1. Reputation Researching the supplier's reputation is critical. Look for customer reviews, testimonials, and case studies that demonstrate their reliability and the quality of their machines.

2. Technical Support A reputable supplier should offer comprehensive technical support, including installation, training, and after-sales service. This support is crucial for maximizing the machine's effectiveness and lifespan.

3. Customization Options Different industries have unique requirements. Suppliers that offer customized solutions can cater specifically to the needs of their clients.

4. Price and Value While cost is always a consideration, it should not be the only factor. It’s essential to evaluate the overall value offered by the supplier, which includes machine performance, durability, and service offerings.

5. Innovation Suppliers that invest in research and development tend to offer advanced machines that incorporate the latest technology, resulting in better efficiency and output quality.

Conclusion

As stainless steel products continue to dominate various industries, the need for high-quality polishing solutions becomes imperative. Selecting the right stainless steel pipe polishing machine supplier can significantly impact product quality, operational efficiency, and profitability. By evaluating suppliers based on their reputation, support, customization capabilities, and technological innovation, manufacturers can ensure they invest in equipment that meets their long-term needs. In this ever-evolving industry, making informed choices can pave the way for success and growth.