The Importance of Stainless Steel Pipe Polishing Machines

Stainless steel, celebrated for its resistance to corrosion and remarkable durability, is a critical material in various industries, including construction, automotive, food processing, and healthcare. However, the aesthetic appeal and functional performance of stainless steel products heavily depend on the quality of their surface finish. This is where stainless steel pipe polishing machines come into play, offering significant advantages in enhancing the appearance and properties of stainless steel pipes.

Understanding Stainless Steel Pipe Polishing

Polishing stainless steel pipes involves the use of specialized machinery to achieve a smooth, shiny surface devoid of imperfections. The process not only improves the visual appeal but also enhances the material's resistance to corrosion and contamination. Polished surfaces are less likely to harbor bacteria, making them ideal for applications in health-sensitive environments such as hospitals and food manufacturing plants.

The process of polishing can take several forms, including mechanical polishing, electro-polishing, and chemical polishing. Each method has its own set of advantages, and the choice of technique often depends on the specific requirements of the project at hand.

Types of Stainless Steel Pipe Polishing Machines

Stainless steel pipe polishing machines vary in design, complexity, and functionality. Some of the most common types include

1. Rotary Polishing Machines These machines operate using rotating brushes or pads that effectively remove surface imperfections while creating a polished finish. They are suitable for various pipe diameters and can handle both straight and curved pipes.

2. Cylindrical Grinding Machines Specifically designed for achieving high precision, these machines utilize grinding wheels to smooth the surface of stainless steel pipes. They are often used in manufacturing processes where tolerances are tight and surface finish quality is paramount.

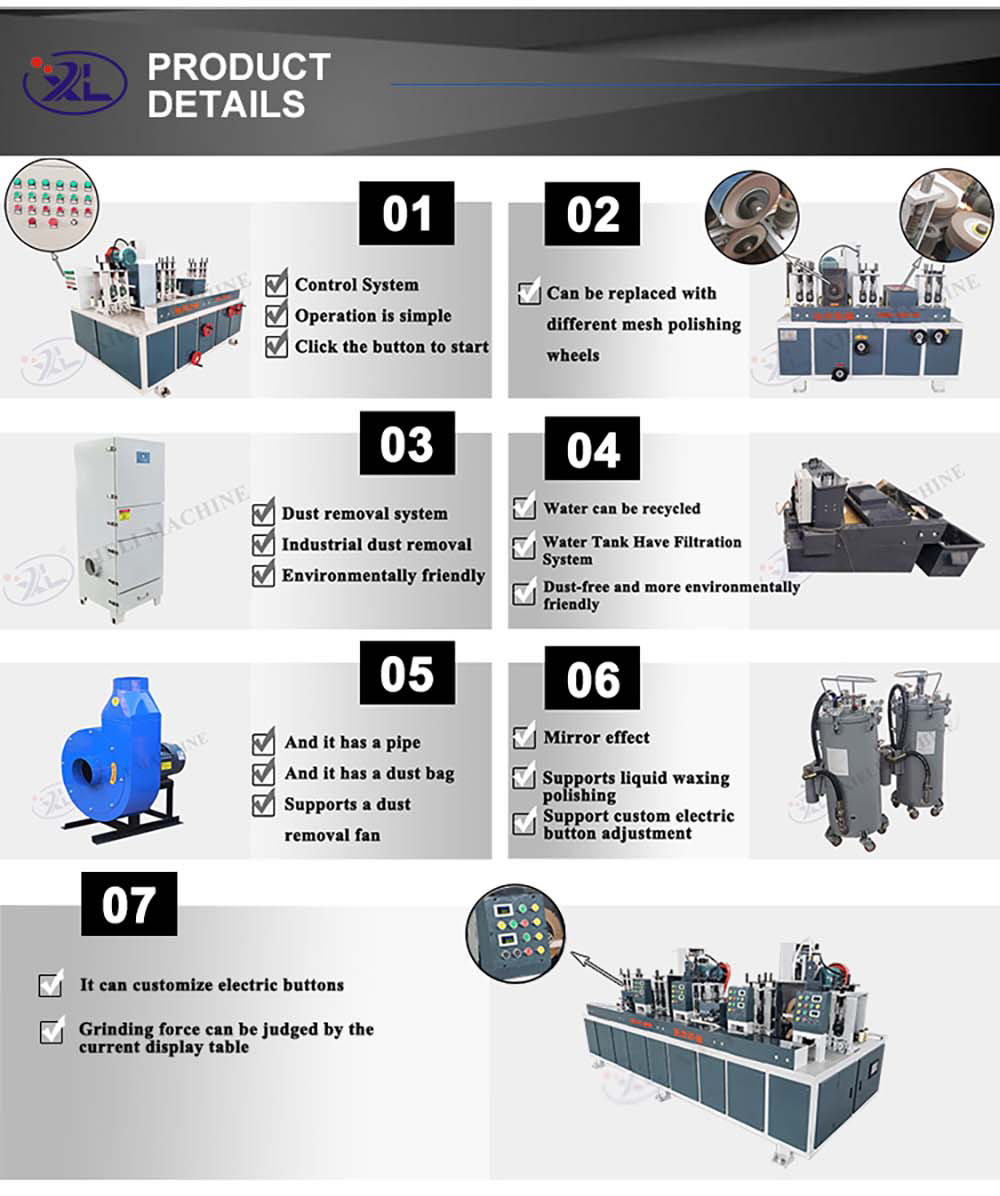

3. Automatic Polishing Machines For large production runs, automatic polishing machines offer efficiency and consistency. These machines can handle multiple pipes simultaneously and are often equipped with advanced technology to monitor and adjust operating conditions in real-time.

stainless steel pipe polishing machine products

4. Bench Polishing Machines Typically used in smaller workshops, these machines provide a simple yet effective solution for polishing stainless steel pipes. They are portable and easy to operate, making them ideal for less intensive polishing jobs.

Benefits of Using Polishing Machines

Investing in stainless steel pipe polishing machines provides numerous benefits

1. Enhanced Surface Quality The primary advantage of polishing machines is the significant improvement in the surface finish of stainless steel pipes. A smooth surface reduces friction, improves flow characteristics, and increases the pipe's lifespan.

2. Increased Efficiency Manual polishing methods can be labor-intensive and time-consuming. Polishing machines automate much of this process, allowing for higher output rates, reduced labor costs, and consistent results.

3. Health and Safety Improvements By producing smoother surfaces, polishing machines contribute to a reduction in bacteria accumulation. This is particularly important in environments where hygiene is critical, such as in the food industry and healthcare sectors.

4. Versatility Stainless steel pipe polishing machines can be adapted for various sizes and types of pipes, enabling manufacturers to handle different orders without the need for multiple machines.

5. Cost-Effectiveness While the initial investment in polishing machinery may seem substantial, the long-term benefits—ranging from reduced labor costs to lower rejection rates due to surface defects—make it a cost-effective solution for manufacturers.

Conclusion

In conclusion, the role of stainless steel pipe polishing machines in both enhancing the aesthetic appeal and functional characteristics of stainless steel pipes cannot be overstated. With advancements in technology, modern polishing machines are designed to offer improved efficiency, consistency, and versatility, making them an invaluable asset in various manufacturing sectors. As businesses continue to prioritize quality and hygiene, the importance of these machines will only increase, ensuring that stainless steel remains a preferred material for countless applications. Investing in high-quality polishing technology is essential for manufacturers looking to maintain competitiveness in an ever-evolving market.