The Importance of Stainless Steel Pipe Grinding Machines in Modern Manufacturing

In the realm of modern manufacturing, the efficiency and quality of production processes are critical factors that can significantly impact the bottom line. One of the unsung heroes in this industry is the stainless steel pipe grinding machine. These machines play a vital role in finishing and polishing stainless steel pipes, ensuring they meet the stringent standards required for various applications. This article explores the significance of stainless steel pipe grinding machines, their functioning, and the key factories that produce them.

Understanding Stainless Steel Pipe Grinding Machines

Stainless steel pipe grinding machines are specialized equipment designed to finish the surfaces of stainless steel pipes. These machines employ various grinding techniques to remove imperfections, burrs, and rough spots, ensuring that the final product is smooth and aesthetically pleasing. The grinding process not only enhances the appearance of the pipes but also improves their corrosion resistance, which is crucial for industries where hygiene and durability are paramount, such as food processing and pharmaceuticals.

Typically, these machines come equipped with advanced features that allow for precision grinding and polishing. They may include adjustable speed settings, automated feeding systems, and various grinding accessories that can be tailored to meet specific requirements. The goal is to achieve a high-quality finish that meets or exceeds industry standards, making these machines indispensable in manufacturing environments.

The Manufacturing Process

The manufacturing of stainless steel pipe grinding machines involves several critical steps. Factories must ensure that the components used are of high quality to withstand the rigorous demands of grinding operations. The production process usually begins with the design and engineering of the machine, followed by the selection of durable materials such as high-grade steel and other alloys.

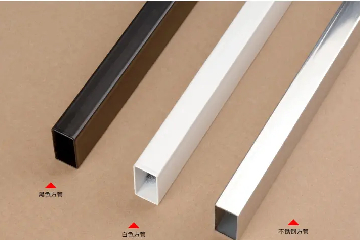

stainless steel pipe grinding machine factories

Once the design is finalized, various manufacturing processes, including cutting, welding, and assembly, are undertaken. A major focus during production is on precision and alignment, as any flaws can lead to inconsistencies in the grinding process. After assembling the machine, extensive testing is performed to ensure it operates efficiently and safely. This quality control is crucial, as any defects can compromise the finishing process and potentially affect the products being processed.

The Role of Factories in Production

Factories that produce stainless steel pipe grinding machines play a vital role in supporting various industries. These factories leverage advanced technologies and skilled labor to create machines that are not only efficient but also adaptable to changing market demands. With the growth of industries such as construction, automotive, and energy, the demand for high-quality stainless steel pipes has surged, making the role of grinding machines even more essential.

Moreover, reputable factories invest in research and development to innovate and improve their products continually. They may also offer customization options, allowing clients to specify certain features or functionalities unique to their production needs. This commitment to quality and innovation helps factories establish a strong presence in the market and build long-term relationships with clients.

Conclusion

In conclusion, stainless steel pipe grinding machines are crucial components in the manufacturing process, particularly for industries that rely on high-quality stainless steel products. The factories that produce these machines are essential to maintaining the quality standards required in today’s competitive market. As technology continues to advance, these factories are poised to adapt and evolve, ensuring that manufacturers have access to the best equipment available. Investing in quality grinding machines not only enhances product quality but also boosts overall efficiency, paving the way for success in the manufacturing sector.