The Crucial Role of Stainless Steel Polishing Machine Suppliers in the Industry

In the modern manufacturing landscape, the significance of stainless steel is undeniable. Its properties — resistant to corrosion, easy to clean, and aesthetically pleasing — make it the material of choice for various industries, from automotive to food production, and even architecture. However, the performance and durability of stainless steel products rely heavily on the finishing process, particularly polishing. This is where stainless steel polishing machine suppliers come into play, offering essential machinery that enhances product quality and operational efficiency.

Understanding Stainless Steel Polishing

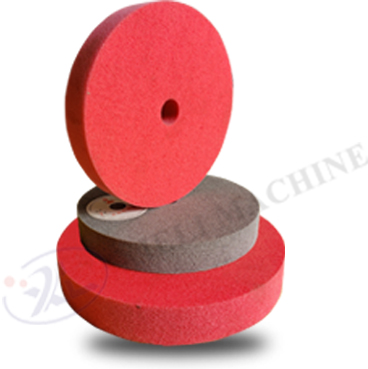

Polishing is a vital step in the production of stainless steel components. It not only affects the appearance of the final product but also its functionality. A well-polished surface improves corrosion resistance, reduces friction, and prevents the accumulation of bacteria, making it particularly important in the food and pharmaceutical sectors. The polishing process can vary from mechanical methods, such as using grinders and buffing wheels, to chemical polishing techniques that provide a uniform finish.

The Role of Polishing Machine Suppliers

Suppliers of stainless steel polishing machines are critical partners in the manufacturing ecosystem. They provide the equipment necessary to achieve high-quality finishes, which can directly influence a manufacturer’s productivity and customer satisfaction. These suppliers offer a range of machines, designed to cater to different polishing needs, budgets, and production scales.

1. Quality and Innovation Leading suppliers invest in research and development to produce advanced polishing machines that incorporate the latest technologies. Features like automated polishing, CNC controls, and smart algorithms significantly enhance the efficiency and consistency of the polishing process. High-quality polishing machines can dramatically reduce the time taken to achieve the desired finish, thus allowing manufacturers to meet tight deadlines without compromising quality.

2. Customization and Flexibility Every manufacturing organization has its own set of requirements, which can be influenced by factors such as the scale of production and the types of stainless steel products being produced. Reputable polishing machine suppliers offer customizable solutions tailored to specific needs. This flexibility ensures that businesses can optimize their operations and maintain competitiveness in the market.

3. Technical Support and Training Beyond supplying machines, many stainless steel polishing machine suppliers offer invaluable technical support and training to their customers. This assistance is critical, as it ensures that personnel can operate the machines effectively and safely. Proper training minimizes the risk of accidents and equipment damage, ultimately contributing to a smoother production process.

stainless polishing machine suppliers

4. After-Sales Services An often-overlooked aspect of working with polishing machine suppliers is their after-sales support. These suppliers typically provide maintenance services, spare parts, and troubleshooting assistance. A reliable after-sales service ensures that machines remain operational, thereby reducing downtime and enhancing productivity.

Choosing the Right Supplier

When selecting a stainless steel polishing machine supplier, several factors must be considered

- Reputation and Experience Look for suppliers with a strong track record and extensive experience in the industry. Customer testimonials and case studies can provide insight into their reliability and performance. - Range of Equipment A supplier that offers a diverse range of polishing machines gives manufacturers the flexibility to choose equipment that precisely meets their requirements.

- Warranty and Support Adequate warranty terms and robust customer support are indicators of a supplier’s confidence in their products and commitment to their customers.

- Sustainability Practices In today’s environmentally conscious market, suppliers that implement sustainable practices in their operations and offer energy-efficient machines are preferable.

Conclusion

In summary, stainless steel polishing machine suppliers are indispensable partners for businesses aiming to maintain high-quality standards in their products. Their role extends beyond merely providing equipment; they contribute to innovation, operational efficiency, and customer satisfaction. By understanding the importance of polishing and selecting the right supplier, manufacturers can enhance their processes, leading to better products and, ultimately, a stronger position in the competitive marketplace. As industries continue to evolve, the demand for high-quality stainless steel products and the expertise of polishing machine suppliers will remain critical components of successful manufacturing.