The Role of Stainless Steel Pipe Grinding Machines in Modern Manufacturing

In the realm of modern manufacturing, the quality and finish of stainless steel pipes are crucial for various industries, including construction, automotive, and food processing. To achieve the desired surface finish, stainless steel pipe grinding machines have become indispensable tools in factories across the globe. These machines not only enhance the aesthetic appeal of stainless steel components but also improve their corrosion resistance, thereby extending their lifespan.

Stainless steel pipes are renowned for their strength, durability, and resistance to corrosion, making them the material of choice for numerous applications. However, when these pipes are cut, welded, or fabricated, they often exhibit rough edges and surface imperfections. This is where grinding machines play a pivotal role. These machines utilize abrasive materials to smoothen the surface of the pipes, removing any irregularities and ensuring a polished, uniform finish.

One of the primary advantages of using stainless steel pipe grinding machines is their efficiency. Automating the grinding process significantly reduces the time required for manual polishing and finishing. Factories equipped with advanced grinding machines can produce high volumes of polished pipes in a fraction of the time it would take using traditional methods. This increase in productivity translates to cost savings and improved competitiveness in the market.

stainless steel pipe grinding machine factories

Furthermore, modern grinding machines are designed to accommodate various sizes and types of stainless steel pipes. Whether the requirement is for industrial-sized pipes or smaller diameter options, specialized machines can be configured to meet diverse production needs. This versatility makes them an essential investment for factories looking to expand their product offerings.

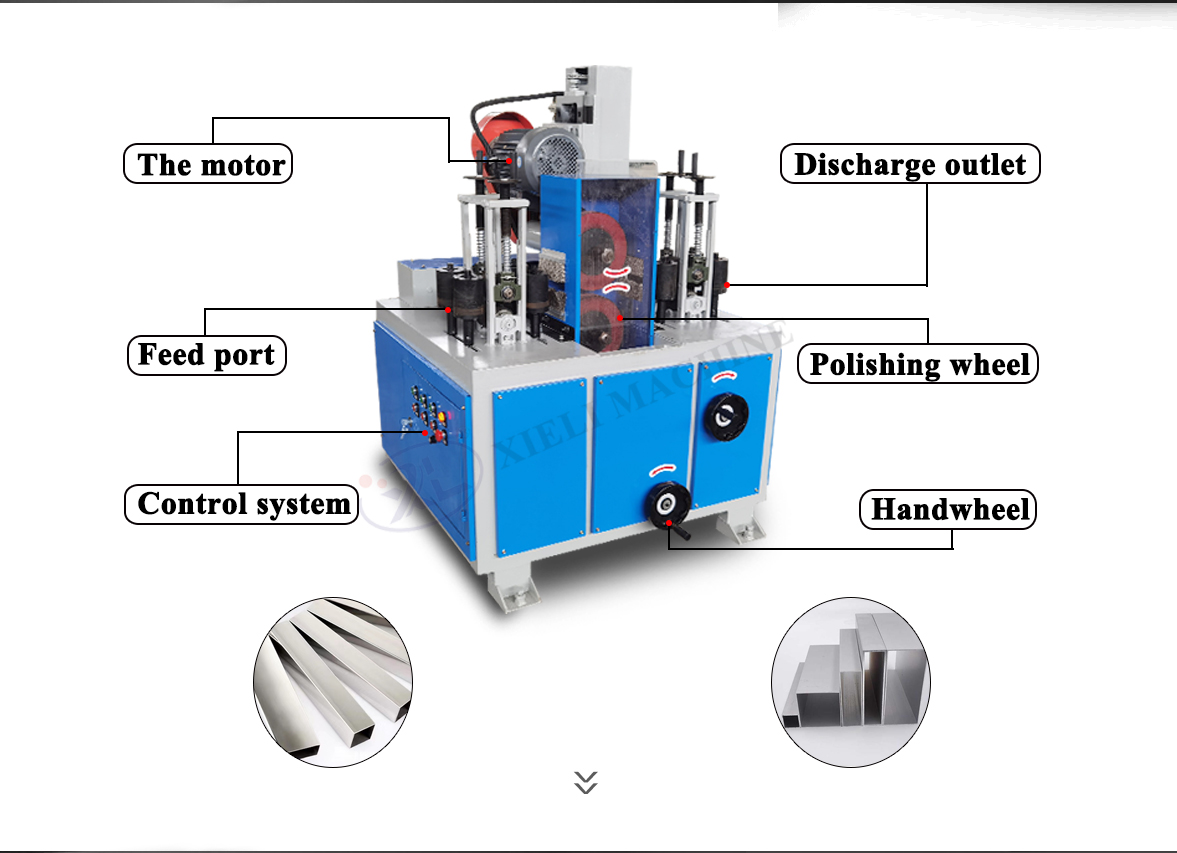

Moreover, the integration of technology in stainless steel pipe grinding machines has revolutionized the manufacturing process. Many machines are now equipped with digital controls and automation features, allowing for precise adjustments and consistent quality across batches. With programmable settings, operators can easily switch between different pipe specifications, thereby reducing setup times and minimizing waste.

The importance of maintaining a clean and safe working environment cannot be overstated. Stainless steel pipe grinding machines come with built-in dust extraction systems that collect metal particles and abrasive dust during the grinding process. This not only enhances the working conditions for operators but also ensures that the finished products are free of contaminants, which is particularly critical in industries such as food and pharmaceuticals.

In conclusion, stainless steel pipe grinding machines are vital assets in modern manufacturing environments. Their ability to deliver high-quality finishes efficiently makes them indispensable for factories focused on producing stainless steel products. As technology continues to advance, these machines will become even more sophisticated, offering enhanced capabilities that will further streamline the manufacturing process. Investing in state-of-the-art grinding equipment is not just a choice; it is a strategic decision that can significantly boost a factory’s productivity and reputation in the competitive landscape of the stainless steel industry.