Understanding SS Square Tube Polishing Machine Suppliers

In the realm of metal processing and manufacturing, the demand for high-quality finishes on products has never been greater. Among the various components used in numerous industries, stainless steel (SS) square tubes are prevalent due to their strength, durability, and resistance to corrosion. As industries seek to enhance the aesthetic and functional qualities of these tubes, the role of stainless steel square tube polishing machine suppliers becomes increasingly significant.

A stainless steel square tube polishing machine is designed specifically to provide a smooth, mirrored finish on stainless steel tubes, which is crucial for both aesthetic appeal and functional integrity. This polishing process helps in removing surface imperfections, enhancing corrosion resistance, and improving the overall surface quality. As a result, manufacturers across various sectors, including construction, automotive, and food processing, rely heavily on these machines.

Market Overview

The global market for stainless steel square tube polishing machines is witnessing substantial growth. As industries expand and evolve, the need for advanced machinery that can enhance productivity and improve the quality of finishes becomes paramount. Suppliers of these machines are not only focused on providing state-of-the-art technology but also on ensuring that their products meet the specific needs of their clients.

Key Features of Polishing Machines

Stainless steel square tube polishing machines come equipped with numerous features that cater to the diverse requirements of manufacturers. These machines often include adjustable speed settings, which allow operators to control the polishing intensity based on the specific characteristics of the tube. Additionally, many modern machines utilize automatic feeding systems, reducing manual labor and increasing efficiency.

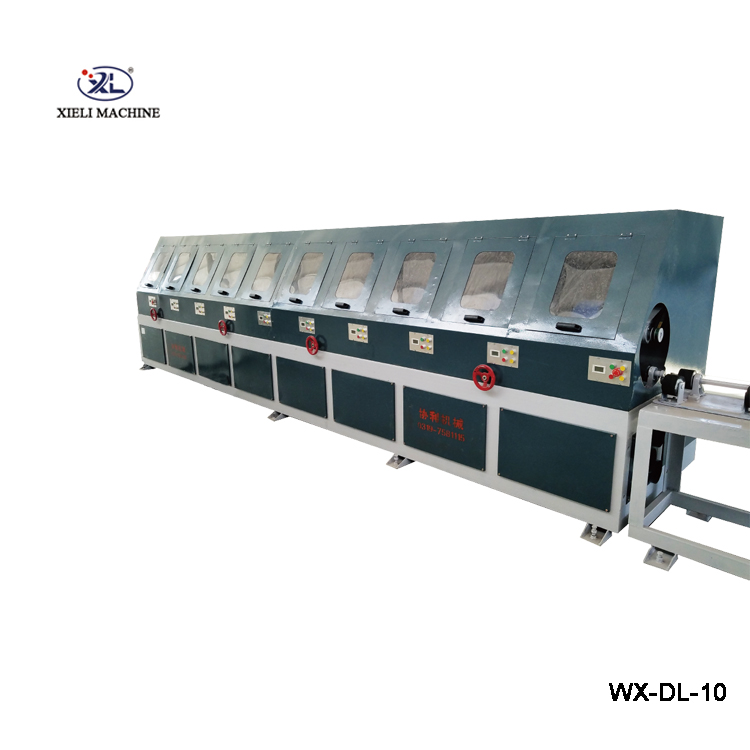

ss square tube polishing machine suppliers

Another significant aspect is the integration of advanced technology, such as CNC (Computer Numerical Control) capabilities, which enhances precision and consistency in finishing. Suppliers are also increasingly focusing on energy-efficient designs that help reduce operational costs while maintaining high performance.

Choosing the Right Supplier

When looking for stainless steel square tube polishing machine suppliers, it's crucial to evaluate several factors. First, consider the supplier's reputation in the industry. Reliable suppliers often have a history of delivering high-quality machines and excellent customer service. Reading customer reviews and asking for references can provide valuable insights.

Secondly, assess the range of machines offered. A supplier that provides a variety of options may better meet your specific needs, whether you require a machine for small-scale operations or a high-capacity model for larger projects.

Additionally, consider the level of support and service offered by the supplier. A knowledgeable and responsive support team can make a significant difference, especially during installation and maintenance.

Conclusion

In sum, as industries continue to grow and evolve, the significance of stainless steel square tube polishing machines cannot be overstated. Suppliers play a crucial role in this dynamic market by providing innovative solutions that enhance product quality and operational efficiency. By carefully selecting suppliers who offer advanced technology, reliable service, and a diverse range of machines, manufacturers can ensure they stay competitive in an increasingly demanding landscape. As the focus on quality and sustainability intensifies, the partnership between manufacturers and machine suppliers will become even more essential in driving progress and innovation in the metal processing industry.