The Evolution and Importance of Stainless Steel Square Tube Polishing Machines

In the world of manufacturing and metalworking, the finishing of products plays a crucial role in ensuring quality and aesthetics. Among the various techniques utilized for metal finishing, polishing stands out as a key process, especially for stainless steel square tubes. These tubes find applications in a wide range of industries, from construction to automotive. With the increasing demand for high-quality polished stainless steel products, the role of stainless steel square tube polishing machine manufacturers has never been more significant.

Understanding Stainless Steel Polishing

Stainless steel is a favored material due to its durability, corrosion resistance, and aesthetic appeal. However, its natural surface often requires additional processing to achieve the desired finish. Polishing involves the use of machines that smooth out the surface, removing imperfections and enhancing the material's luster. This not only increases the aesthetic appeal but also improves the steel's resistance to corrosion and increases its lifespan.

The Role of Polishing Machines

Stainless steel square tube polishing machines are specialized devices designed to automate the polishing process. These machines come in various configurations depending on the size of the tubes, the desired finish, and the production volume. Manufacturers have developed machines that can accommodate different diameters and wall thicknesses, ensuring flexibility and efficiency in production lines.

Types of Polishing Machines

There are several types of stainless steel square tube polishing machines available in the market today

1. Belt Polishers Utilized for their simplicity and efficiency, belt polishers use abrasive belts to achieve a high-quality finish. They are particularly suited for continuous operations and can process multiple tubes simultaneously.

2. Disc Polishers These machines employ rotating discs covered with various abrasive materials to polish the surface of the tubes. They are often used for finer finishes and can easily adjust to achieve different levels of sheen.

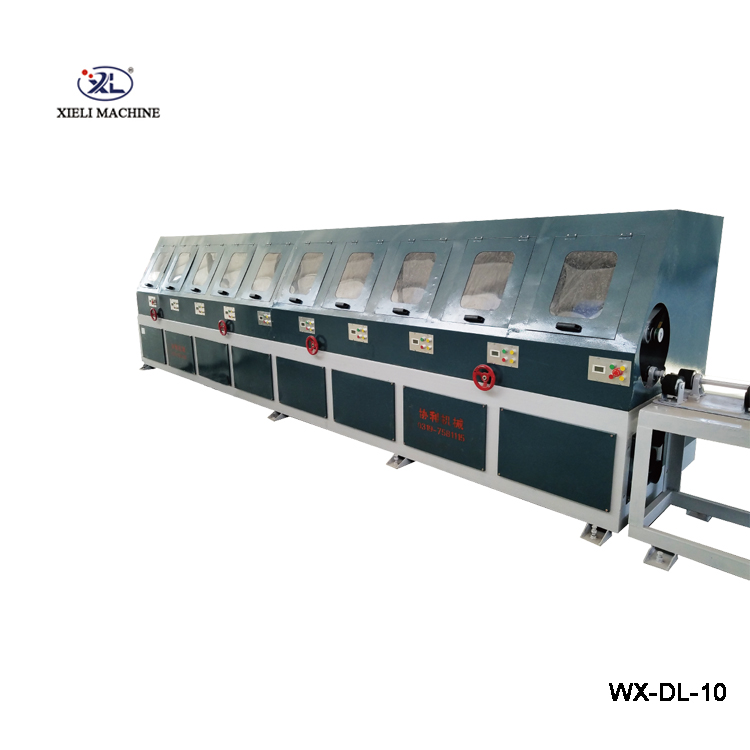

ss square tube polishing machine manufacturers

3. Cylindrical Polishers Typically designed for round sections, some manufacturers have adapted these machines for square tubes, ensuring uniform polishing even on challenging geometries.

4. Robotic Systems The advent of automation has led to the incorporation of robotic systems in polishing processes. These machines provide high precision and can work in environments that are less suitable for human workers.

Choosing a Manufacturer

When selecting a manufacturer for stainless steel square tube polishing machines, there are several factors to consider

- Experience and Expertise Choose manufacturers with a proven track record and extensive experience in the industry. Their expertise will be invaluable in providing the right equipment tailored to specific needs.

- Technology and Innovation Modern manufacturers often utilize the latest technologies to improve efficiency and effectiveness. Look for features such as programmable logic controllers (PLCs), touch screen interfaces, and IoT capabilities for easier monitoring and operation.

- Customization Options Not all polishing needs are the same. A reputable manufacturer should offer customization options to accommodate specific requirements regarding tube dimensions, finishes, and production speed.

- After-Sales Support Ensure the manufacturer provides adequate after-sales support, including maintenance and repair services. This is essential to minimize downtime in production.

Conclusion

The demand for polished stainless steel square tubes is unlikely to diminish, serving various sectors with aesthetics and functionality. Stainless steel square tube polishing machine manufacturers play a vital role in meeting this demand, driving innovations in the polishing process, and continuously adapting to the evolving needs of the industry. As manufacturers strive for excellence and efficiency, the technology behind these polishing machines will continue to evolve, paving the way for higher quality products and more sustainable practices in metalworking. Investing in high-quality polishing machines is not just an operational decision but a commitment to producing superior products that can stand the test of time.