The Importance of Quality in SS Square Tube Polishing Machine Manufacturing

In today's fast-paced manufacturing landscape, the demand for high-quality stainless steel products has surged significantly. Among these products, stainless steel square tubes have gained popularity due to their versatility, corrosion resistance, and aesthetic appeal. However, the production of these tubes involves several processes, one of which is polishing. A crucial component in this process is the SS square tube polishing machine, and the role of manufacturers in producing high-quality machines cannot be overstated.

Understanding SS Square Tube Polishing Machines

SS square tube polishing machines are specialized equipment designed to enhance the surface finish of stainless steel square tubes. Polishing not only improves the aesthetic quality of the tubes but also prepares them for further applications, including architectural, industrial, and decorative uses. The machines typically utilize abrasive materials and advanced techniques to achieve the desired finish, which can range from a matte to a mirror-like surface.

Key Features of Quality Polishing Machines

A well-manufactured polishing machine should exhibit several key features

1. Durability Since polishing operations can be intense due to the friction and abrasiveness involved, the machine must be constructed from durable materials capable of withstanding harsh conditions over extended periods.

2. Precision Engineering The machines should be designed with high levels of precision to ensure that the polishing process is consistent and uniform across multiple tubes. This precision is essential to maintain product quality and standards.

3. Efficiency A high-quality polishing machine should maximize output while minimizing production time. Innovative designs that allow for automation and quicker changeovers between different tube sizes and finishes are increasingly important.

4. User-Friendly Interface With the rising complexity of technology, a user-friendly interface is crucial. Operators should find it easy to adjust settings and troubleshoot issues without needing extensive technical training.

ss square tube polishing machine manufacturer

5. Safety Features Given the nature of the polishing process, safety features should be incorporated to protect operators and reduce the risk of accidents.

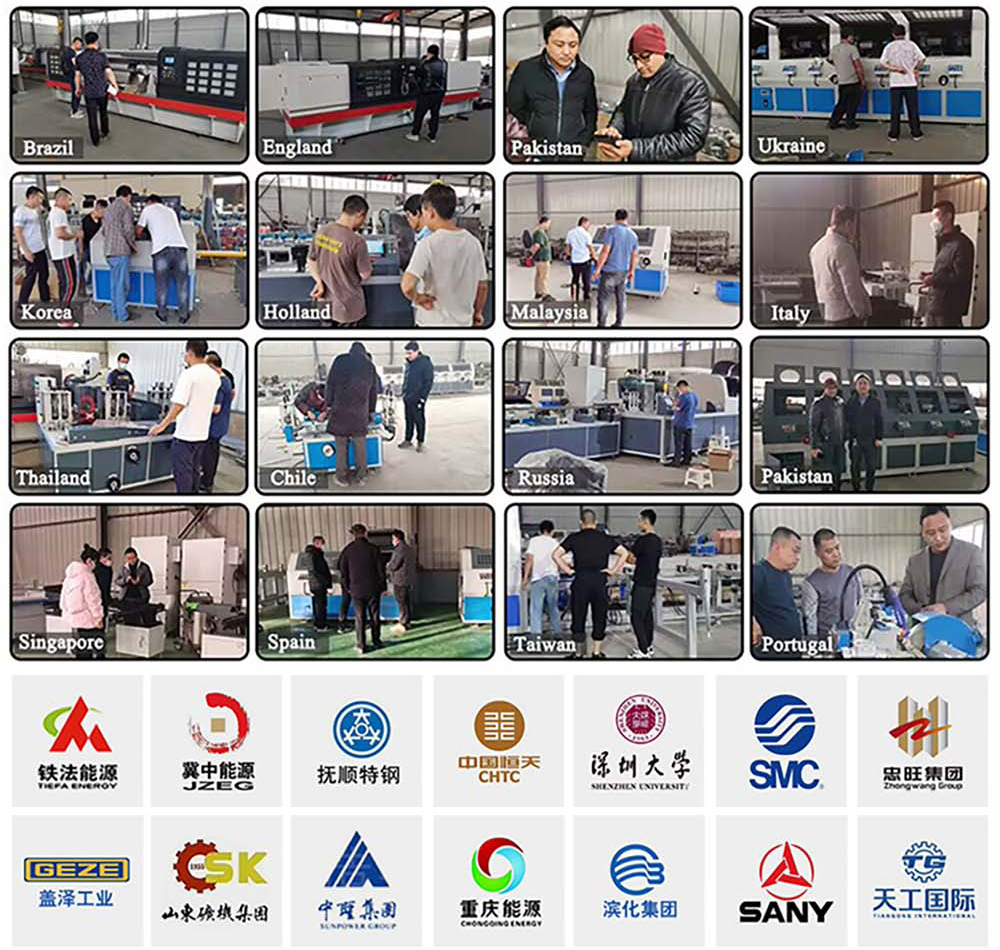

The Role of Manufacturers

Manufacturers play a pivotal role in the development of SS square tube polishing machines. They are responsible for researching and integrating the latest technologies and techniques to enhance machine performance and reliability. A manufacturer focused on quality often engages in rigorous testing and quality control measures, ensuring that each machine meets industry standards before reaching the market.

The best manufacturers also offer customization options, allowing clients to specify unique requirements and modifications based on their specific production needs. This level of service not only enhances customer satisfaction but also fosters long-term relationships between manufacturers and their clients.

Challenges Faced by Manufacturers

Despite the focus on quality, manufacturers of SS square tube polishing machines face several challenges. The rapid pace of technological advancements calls for continuous innovation and adaptation. Manufacturers must invest in research and development to stay ahead of competitors and respond to evolving market demands.

Additionally, the global supply chain can be complex and unpredictable. Sourcing high-quality materials at competitive prices while ensuring timely delivery remains a significant hurdle for many manufacturers. Navigating these challenges requires strategic planning and a commitment to excellence.

Conclusion

As industries continue to grow and diversify, the demand for high-quality stainless steel square tubes will persist. The critical role of SS square tube polishing machine manufacturers cannot be underestimated in this context. By focusing on durability, precision, efficiency, and safety, manufacturers can provide essential tools that help businesses produce top-grade products. In an increasingly competitive market, quality will always set the leaders apart from the rest, making the selection of a reliable manufacturing partner more important than ever.