The Importance of SS Polishing Machines in Modern Manufacturing

In the competitive world of manufacturing, the aesthetic appeal and surface finish of products can often be just as important as their functionality. This is particularly true in industries such as automotive, aerospace, and consumer goods, where the visual impact of a product can significantly affect sales and customer satisfaction. Among the various machines used in the production process, SS polishing machines have gained prominence due to their efficiency and ability to deliver high-quality finishes on stainless steel surfaces.

Understanding SS Polishing Machines

SS polishing machines, also known as stainless steel polishing machines, are specialized equipment designed to enhance the appearance and smoothness of stainless steel surfaces. These machines utilize various polishing techniques, including buffing, grinding, and surface finishing, to remove imperfections and achieve a mirror-like finish. They are crucial in the preparation of stainless steel products, which are widely used in kitchens, medical facilities, and various industrial applications due to their resistance to corrosion and hygiene properties.

Types of SS Polishing Machines

There are several types of polishing machines available on the market, each catering to different needs and applications. Some of the most common types include

1. Belt Polishers These machines use a continuous belt that rotates around a series of rollers. The belt is coated with abrasive materials that help remove tarnish and imperfections from the stainless steel surface.

2. Disc Polishers Disc polishing machines feature rotating discs equipped with various abrasives. They are suitable for polishing small to medium-sized surfaces and can achieve high gloss finishes.

3. Cylindrical Polishers Designed for cylindrical objects, these machines enable the polishing of round surfaces and can be adjusted for length and diameter.

4. Robotic Polishers For advanced manufacturing processes, robotic polishing machines offer automation with high precision, allowing manufacturers to maintain consistent quality while reducing labor costs.

Benefits of Using SS Polishing Machines

The integration of SS polishing machines into manufacturing processes provides several notable benefits

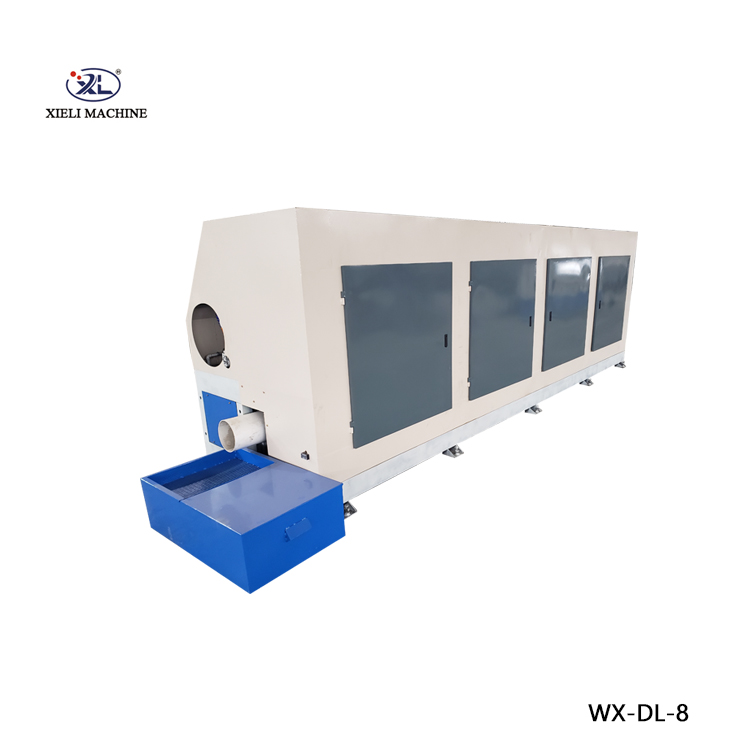

ss polishing machine product

- Improved Aesthetics A polished stainless steel surface is not only visually appealing but also reflects light, enhancing the overall look of the finished product. This can be especially beneficial in consumer products where first impressions matter.

- Increased Durability Polishing helps to remove microscopic imperfections that could lead to corrosion or rust. By creating a smoother surface, these machines contribute to the longevity of stainless steel products.

- Enhanced Hygiene In industries such as food processing and healthcare, the ability to keep surfaces smooth and free from contaminants is crucial. Polished stainless steel surfaces are easier to clean and sanitize, reducing the risk of contamination.

- Cost Efficiency While the initial investment in high-quality polishing machinery might be significant, the long-term savings in terms of reduced labor and increased product quality make them a smart investment for many manufacturers.

Considerations When Choosing an SS Polishing Machine

When selecting an SS polishing machine, manufacturers should consider several factors to ensure they choose the right equipment for their needs

1. Type of Material Different grades of stainless steel may require specific polishing techniques. Therefore, it is essential to choose a machine compatible with the type of material being polished.

2. Production Volume The scale of production will dictate the type of polishing machine required. For high-volume operations, automated or robotic machines may provide the efficiency needed to meet production goals.

3. Finish Quality Consider the desired finish quality. Different machines and attachments can deliver varying results, so it's crucial to select the right combination for the intended application.

4. Maintenance and Support Look for manufacturers that offer reliable customer support and service, as maintaining polishing machines is vital for consistent performance and longevity.

Conclusion

In summary, SS polishing machines play a pivotal role in modern manufacturing processes, especially for stainless steel products. Their ability to enhance surface quality not only contributes to product aesthetics and durability but also plays a critical role in maintaining hygiene standards in various industries. As manufacturing continues to evolve, the importance of advanced polishing technology will only increase, making it an essential part of any production line that values quality and efficiency.