In the industrial world, where precision and quality are paramount, the importance of a reliable SS pipe polishing machine cannot be overstated. These machines, integral to ensuring that stainless steel pipes meet the highest standards, play a pivotal role in various industries, from automotive to aerospace. Through years of hands-on experience in the field of metal finishing, I've come to appreciate the nuances of these machines, underscoring their indispensable nature in manufacturing.

At the core of a superior SS pipe polishing machine's design is its ability to deliver consistent and quality finishes. From mirror finishes that gleam under the light to functional finishes that provide necessary friction or resistance, these machines are engineered for precision. My own journey with SS pipe polishing machines began over a decade ago, when ensuring the optimal output of these machines in a high-demand manufacturing facility was my primary responsibility. The expertise that one gains over time reveals that while the machines are important, understanding the specific needs of each project is critical to their effective usage.

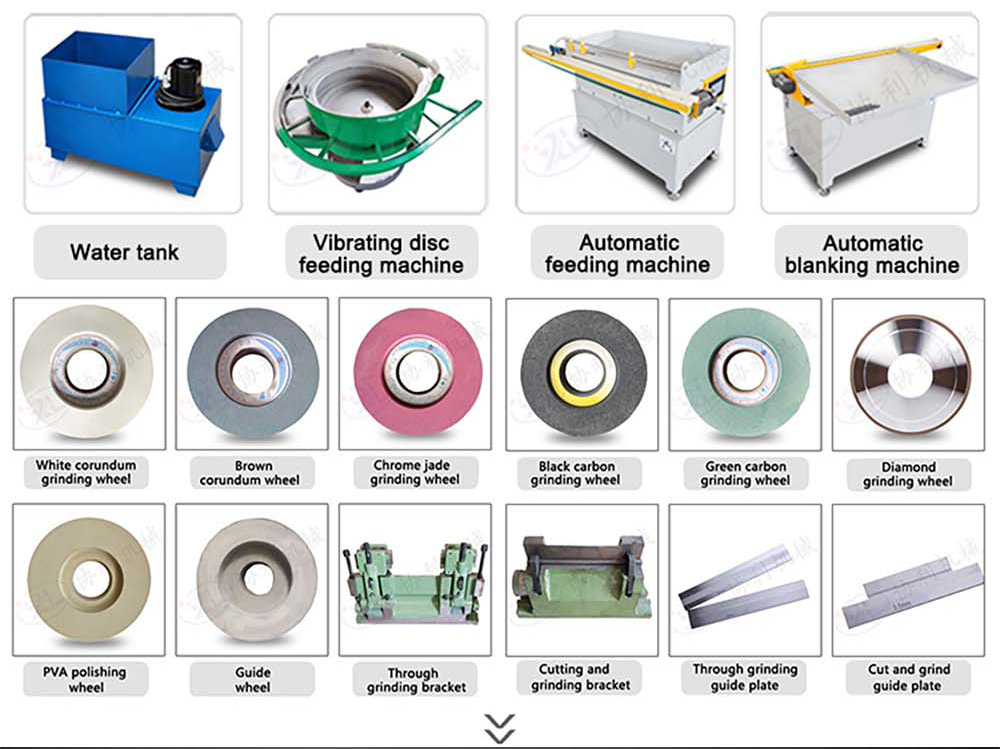

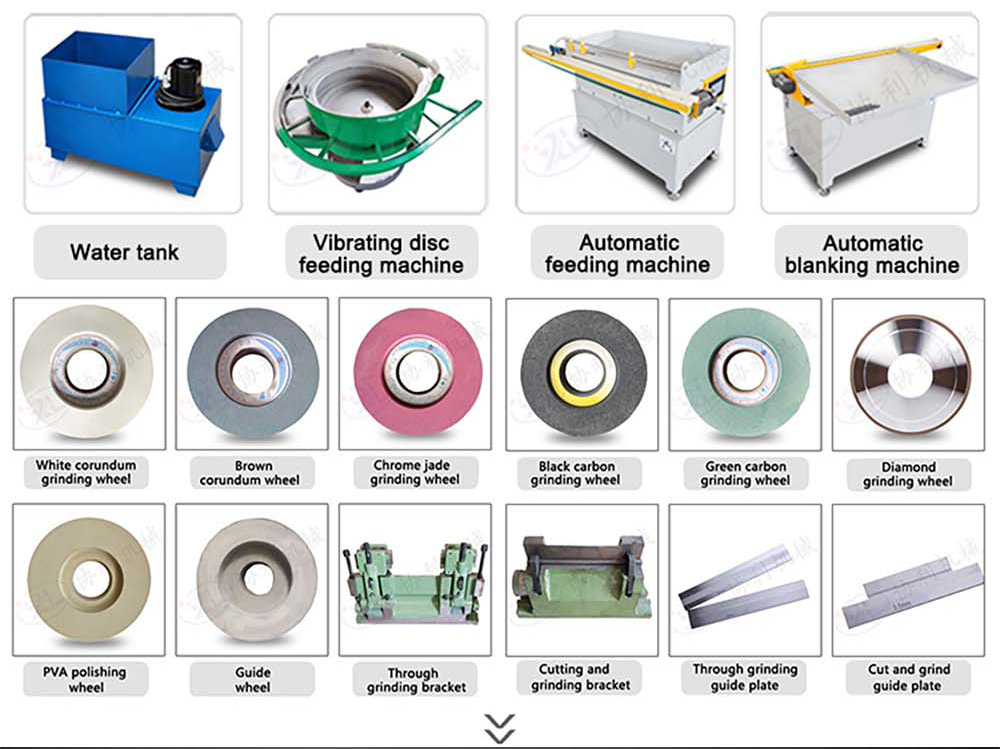

Over the years, technology advancements have greatly enhanced the capabilities of these machines. Today's SS pipe polishing machines are equipped with advanced automation and control systems that offer unparalleled customization. They allow operators to tailor the machining process to meet precise specifications, thus enhancing productivity while maintaining quality. Through professional collaborations and a deep dive into the mechanics of these machines, one realizes the importance of adopting a machine that offers comprehensive functionalities—something only seasoned professionals can truly appreciate.

ss pipe polishing machine products

Trust in the performance of an SS pipe polishing machine is built over years of reliable service, reinforced by manufacturers who continuously improve the technology and educate the operators. Authoritativeness in this领域 stems from understanding that each specification—speed, pressure, grit type—can significantly impact the final product. Early on, I learned that meticulously recording parameters and regularly consulting with machine developers led to optimized results and process improvements. Published findings and successful project completions contribute to a reputation of trustworthiness among clients and peers alike.

In sharing my experiences, it’s critical to highlight that a good SS pipe polishing machine is not a one-size-fits-all solution. The diverse requirements of different projects mean that machine adaptability is as crucial as its initial design. Factors such as the type of stainless steel, its intended use, and environmental considerations must all be factored into the selection and operation of these machines. Conferences, workshops, and seminars have served as great platforms to exchange knowledge and to further understand how these variables play out in different industries around the globe.

Ultimately,

choosing the right SS pipe polishing machine is an investment in quality and efficiency. For manufacturers seeking to maintain a competitive edge, investing in a sophisticated, well-supported machine is crucial. This decision becomes easier with an informed perspective grounded in experience, expertise, and an unwavering commitment to excellence. Through continuous learning and adaptation, industries can harness the full potential of these invaluable machines.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.