When embarking on the task of sourcing a stainless steel (SS) pipe polishing machine, understanding the intricacies of pricing, technical specifications, and supplier credibility is essential. Often, businesses, particularly in the manufacturing and fabrication industry, seek equipment that not only meets their budgetary constraints but also aligns with their production needs. In this article, we'll navigate the elements that influence the pricelist of SS pipe polishing machines and why a comprehensive evaluation is crucial to making an informed choice.

A stainless steel pipe polishing machine is a pivotal tool designed for delivering a smooth and shiny finish to SS pipe surfaces, which is crucial in various applications where aesthetics and corrosion resistance matter. The market for these machines offers various models, each tailored with different capabilities, features, and thus, pricing points.

Understanding Pricing Factors

The pricing of SS pipe polishing machines is not a straightforward figure, largely because it is dictated by a medley of factors including

1. Machine Capacity and Size Typically,

higher-capacity machines are priced higher. A machine designed to handle larger pipes or higher volumes will come at a premium, aligning cost to the workload it can manage effectively.

2. Automation Level Manual machines are usually more affordable, whereas semi-automatic or fully automated machines, equipped with advanced programmable features, hold a higher price tag due to their potential to elevate operational efficiency and reduce labor costs.

3. Brand and Manufacturer Credibility Established brands with a proven track record for manufacturing durable and efficient equipment often charge more. However, this may be justified by their reputation for quality and after-sales service, aspects which are vital for minimizing downtime and ensuring continuous operation.

4. Additional Features Machines offering additional functionalities such as dust collection systems, noise reduction technology, or specialized polishing techniques can influence the cost significantly.

5. Material and Build Quality The quality of materials used in constructing the machine contributes to its durability and effectiveness, thereby influencing its price.

Evaluating Suppliers

ss pipe polishing machine pricelist

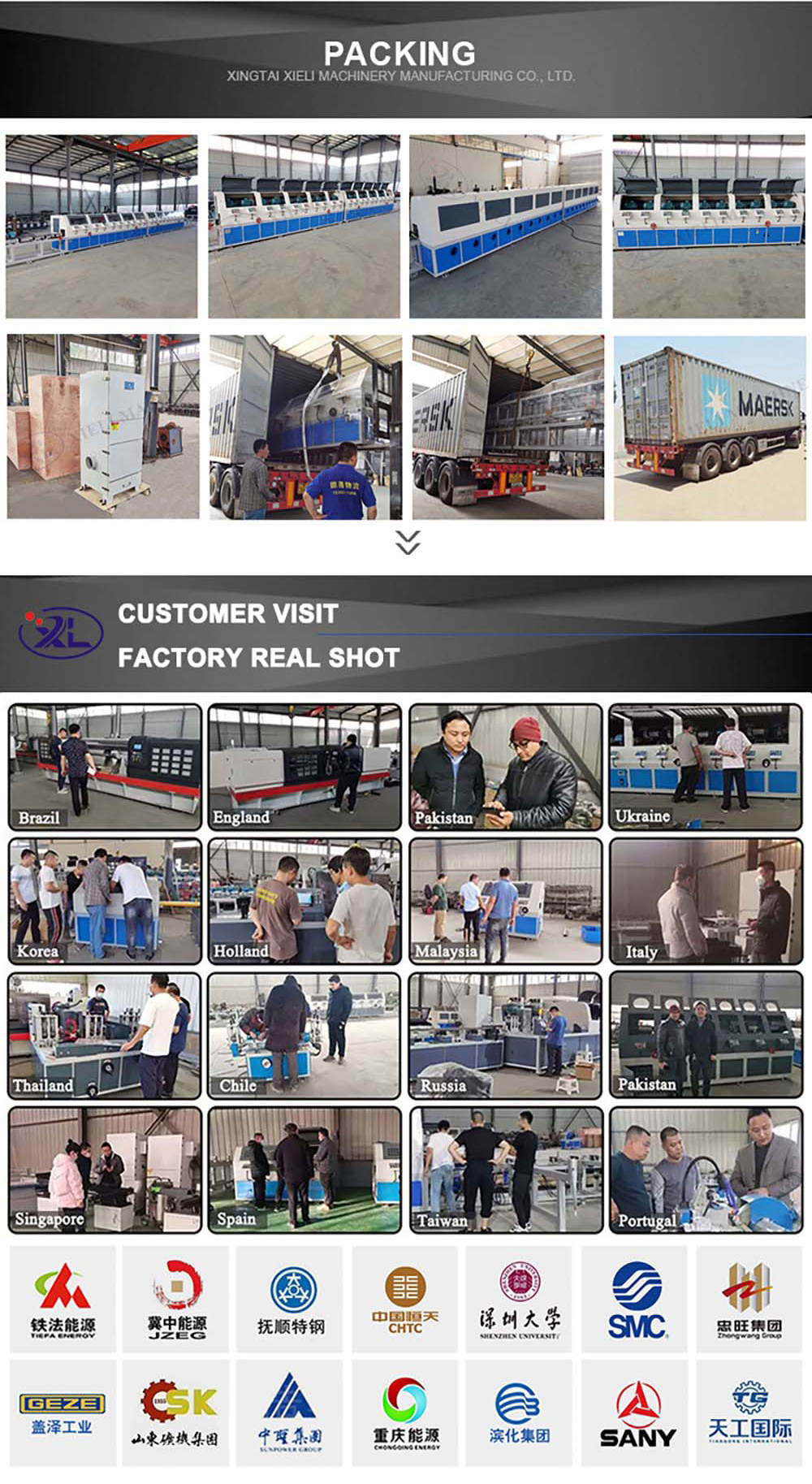

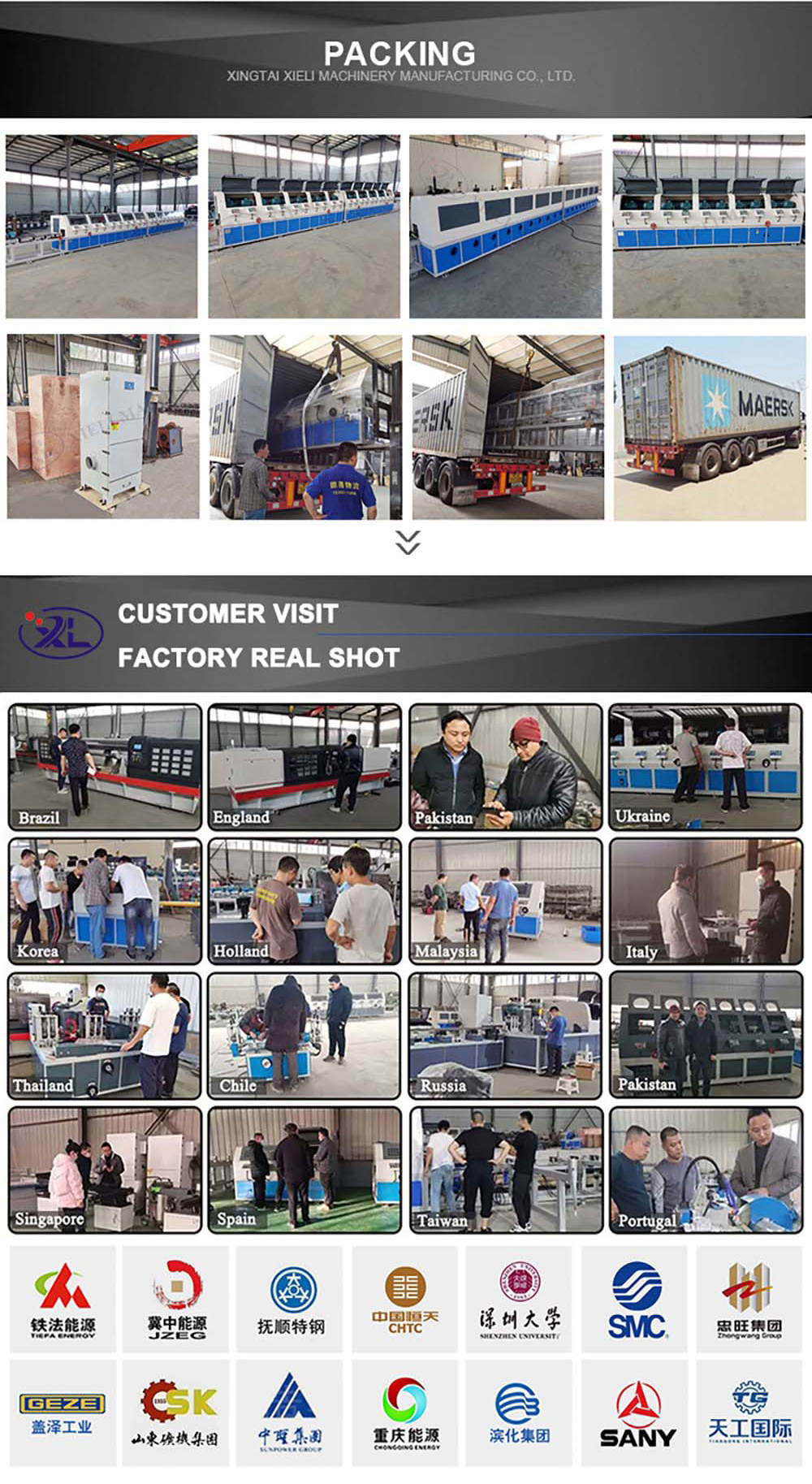

When considering where to purchase an SS pipe polishing machine, it is vital to assess potential suppliers for their credibility and reliability. A reputable supplier can provide not only a transparent pricelist but also present testimonials or case studies demonstrating past success in the industry.

1. Reputation in the Industry Evaluate the supplier’s standing through industry networks or reviews. Long-standing players might offer better warranties and support due to their sustainable business practices.

2. Customer Support and After-Sales Service Reliable customer support can significantly enhance the machine's operational lifecycle, thus applicants should prioritize suppliers with robust service networks.

3. Certifications and Compliance Verify if the machines meet industry standards and certifications. Compliance with international quality standards is a proxy for reliability and safety.

Making an Informed Decision

A thorough needs assessment is a sensible preliminary step before consulting pricelists. Companies should introspect on aspects such as specific production requirements, budget constraints, and space availability. Once these parameters are clear, the focus can shift toward identifying a machine that aligns closely with their operational goals.

Leasing or financing options might be considered for high-end models that offer superior automation and efficiency but come with a higher initial outlay. This allows businesses to leverage advanced technology without draining cash reserves.

Furthermore, conducting site visits and machine demos can provide insights into the operational efficiency and potential ROI of the equipment. Such firsthand experience can be invaluable, offering tangible evidence of a machine's fit for a particular application.

Conclusion

Choosing the right SS pipe polishing machine involves careful consideration of a plethora of factors, each influencing the overall cost and value derived from the purchase. Suppliers willing to engage transparently and offer post-purchase support provide a safety net that is as crucial as the machine itself. Businesses should prioritally focus on aligning their specific operational needs with the machine's capabilities, ensuring that their choice augurs well for both current and future production capabilities. An informed decision not only secures a valuable asset but also supports sustained operational success, cementing a business's competitive edge in a demanding market.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.