Understanding the Price List for SS Pipe Polishing Machines

In the realm of metal finishing, stainless steel (SS) pipe polishing machines play a crucial role in enhancing the aesthetic and functional properties of stainless steel products. These machines are designed to ensure that the surfaces of pipes are not only smooth and clean but also free of contaminants and imperfections. As industries increasingly demand high-quality finishes, understanding the price list and factors affecting the cost of SS pipe polishing machines becomes essential for businesses.

Factors Influencing Pricing

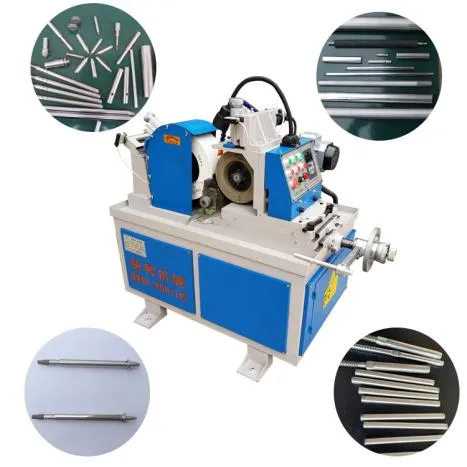

1. Machine Type and Specifications The price of an SS pipe polishing machine will vary significantly based on its type and technical specifications. There are various models available in the market, from manual machines suitable for smaller operations to fully automated systems capable of handling high volumes of production. The more advanced the machinery—incorporating features like digital controls, programmable settings, and multiple polishing stages—the higher the cost.

2. Production Capacity Machines are also priced according to their production capacity. A machine designed to finish a high number of pipes in a shorter amount of time is usually more expensive than one that handles lower volumes. For businesses focused on large-scale production, investing in a higher-capacity machine may offer better returns despite the initial outlay.

3. Material and Build Quality The durability and longevity of the polishing machine often depend on the materials used in its construction. Machines made from high-quality steel and robust components tend to have a higher price tag. Investing in well-built equipment may lead to lower maintenance costs and longer operational life, making it a wise economic decision in the long run.

ss pipe polishing machine pricelist

4. Brand Reputation Established manufacturers with a strong reputation for quality and service may charge a premium for their machines. This often comes with the benefit of better reliability, customer support, and warranty terms. On the other hand, newer or lesser-known brands may offer competitive prices but could lack the same level of support and reliability.

5. Technological Features Modern polishing machines often come equipped with advanced technologies such as CNC (Computer Numerical Control) capabilities, which enhance precision and consistency in polishing operations. Machines with these features tend to be more expensive but can contribute significantly to productivity and finish quality, making them a worthwhile investment for many businesses.

Typical Price Ranges

To give an idea of the market landscape, SS pipe polishing machines generally range in price from a few thousand to tens of thousands of dollars, depending on the factors mentioned above. For instance, a basic manual polishing machine might start at around $2,000, while an advanced automated system could easily exceed $20,000. This variance illustrates the importance of aligning your purchase with your operational needs and budget constraints.

Conclusion

Investing in an SS pipe polishing machine is a significant decision for any business involved in metalworking, and understanding the pricing structure is essential. By considering the various factors that influence costs, such as machine type, production capacity, build quality, brand reputation, and technological advancements, businesses can make informed choices that align with their operational needs. Ultimately, selecting the right machine can lead to improved product quality, increased efficiency, and a positive return on investment in the competitive landscape of stainless steel processing.