The Evolution and Importance of Square Rectangle Tube Polishing Machines

In the realm of metal manufacturing and finishing, the importance of polishing cannot be overstated. Among the various tools available for metal treatment, the square rectangle tube polishing machine stands out due to its efficiency and effectiveness in producing high-quality surfaces on metal tubes. This article explores the significance, features, and advancements in these specialized machines.

Polishing metal tubes is a crucial step in the manufacturing process, especially for industries that demand aesthetic quality and performance. Square rectangle tubes, often utilized in structural applications, conveyance systems, and decorative elements, require a smooth surface to prevent corrosion, improve adhesion for coatings, and enhance visual appeal. The polishing process not only meets these requirements but also ensures that the final product can withstand the rigors of their respective environments.

At the core of a square rectangle tube polishing machine is its ability to handle the specific geometry of the tubes. These machines are designed to accommodate varied sizes and thicknesses, ensuring versatility in production lines. Most modern machines come equipped with advanced features such as automatic feed systems, programmable logic controllers (PLCs), and user-friendly interfaces. Such innovations allow operators to efficiently manage the entire polishing process, reducing labor costs and increasing productivity.

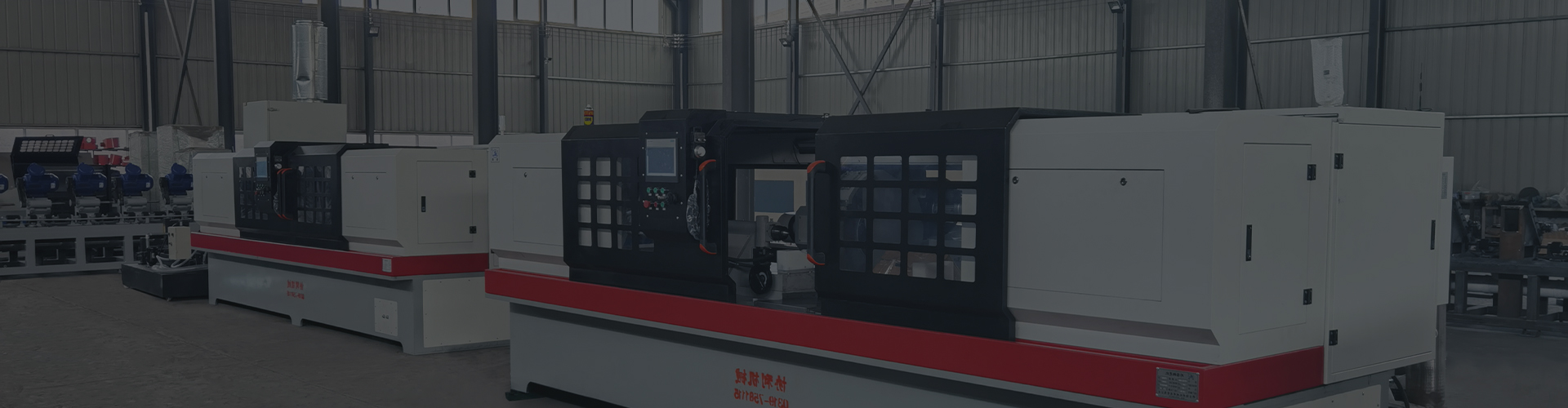

square rectangle tube polishing machine products

One of the notable advancements in tube polishing technology is the transition from manual to automated processes. Traditional methods required extensive labor and time, often resulting in inconsistent finishes. Modern polishing machines use computerized systems to monitor and adjust parameters such as speed, pressure, and abrasiveness. This level of control leads to a uniformly polished surface, significantly increasing quality assurance.

Another key development is the introduction of eco-friendly polishing solutions. Traditionally, metal polishing involved chemicals that could be harmful to both workers and the environment. Nowadays, manufacturers focus on sustainability, utilizing water-based polishing compounds and recycling systems that reduce waste. This shift not only aligns with global trends towards greener manufacturing practices but also enhances workplace safety.

The market for square rectangle tube polishing machines has witnessed considerable growth, reflecting the increasing demand from diverse sectors, including automotive, aerospace, and furniture manufacturing. As industries evolve, the need for high-quality polished tubes continues to rise, driving innovation in machine design and functionality.

In conclusion, square rectangle tube polishing machines play a pivotal role in modern manufacturing. Their ability to provide superior surface finishes, coupled with advancements in technology and eco-friendly practices, makes them indispensable tools across various industries. As the demand for quality and efficiency continues to grow, these machines will undoubtedly evolve, further shaping the future of metal polishing.