Understanding Square Rectangular Tube Polishing Machines and Their Factories

In the modern manufacturing landscape, the finishing process is as crucial as the raw material itself. Among the variety of machinery available, square and rectangular tube polishing machines have garnered significant attention due to their application in enhancing the aesthetic and functional qualities of metal tubes. This article explores the technology behind these machines, their factories, and their pivotal role in various industries.

The Importance of Polishing

Polishing is not merely an aesthetic endeavor; it plays a crucial role in improving corrosion resistance, reducing friction, and providing a smooth surface that is essential for further fabrication processes. Square and rectangular tubes are commonly utilized in industries ranging from construction to automotive, where surfaces must not only meet functional requirements but also appeal to aesthetic demands.

Technology Behind Tube Polishing Machines

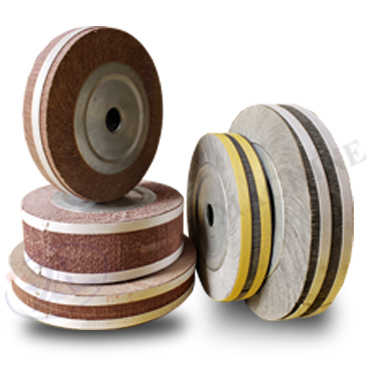

Square rectangular tube polishing machines utilize advanced technology to achieve superior finishes. These machines typically employ a combination of mechanical polishing methods, such as abrasive belts, brushes, and buffing wheels, which allow for precision and efficiency in finishing metal surfaces. The use of automated systems has increased in recent years, as factories strive for higher production rates while maintaining quality standards.

The designs of these machines can vary significantly based on their intended application. For instance, some machines are equipped with multiple spindle configurations to accommodate different tube sizes, while others might integrate CNC technology to allow for customizable polishing patterns. This flexibility makes square rectangular tube polishing machines a prime choice for many manufacturers.

The Role of Factories

square rectangle tube polishing machine factories

Factories that specialize in the production of square rectangular tube polishing machines play a vital role in the manufacturing ecosystem. These facilities not only design and fabricate the machines but also engage in research and development to continually improve polishing technology. The factories are often equipped with state-of-the-art equipment to ensure that each machine meets rigorous quality standards before reaching the market.

Furthermore, these factories often provide customization options according to their clients' specifications, enabling businesses to enhance their operational efficiency. With a growing focus on sustainability, many factories are also investing in eco-friendly technologies, ensuring that their processes comply with global environmental standards.

The Market for Polishing Machines

The demand for square rectangular tube polishing machines is on the rise, driven by the growing need for high-quality metal products. Various sectors, including aerospace, furniture manufacture, and construction, require polished tubes that not only exhibit enhanced performance but also meet user expectations for aesthetic appeal. This market trend encourages factories to expand their production capacities and innovate their designs.

Moreover, globalization has opened up new markets, allowing factories to export their products to international clients. This expansion facilitates knowledge exchange and technological advancements that benefit the entire industry.

Conclusion

Square rectangular tube polishing machines are indispensable elements in modern manufacturing processes, enhancing both the functionality and appearance of metal tubes. The factories that produce these machines are at the forefront of innovation and sustainability, continuing to evolve their practices in response to market demands. As industries become increasingly competitive, the role of technology in machine design and production will be paramount, ensuring that manufacturers can deliver high-quality products that meet the expectations of their customers. In this dynamic landscape, square rectangular tube polishing machines will undoubtedly remain a cornerstone of industrial efficiency and product excellence.