The Evolution and Importance of Square Pipe Polishing Machines

In today's manufacturing landscape, the finishing and aesthetic quality of metal products is of paramount importance. Among these items, square pipes play a crucial role in various applications, from construction to automotive industries. Ensuring that these pipes have a polished, high-quality finish is where square pipe polishing machines come into play. This article explores the significance of these machines and the factors to consider when choosing a supplier.

Square pipe polishing machines are designed to provide a smooth and shiny surface to square and rectangular pipes, which can enhance both their appearance and performance. These machines effectively remove any imperfections or oxidations, essential for maintaining the material’s durability and resistance to corrosion. The polishing process can also prepare the pipes for further processing or coating, thus making them suitable for a variety of end-use applications.

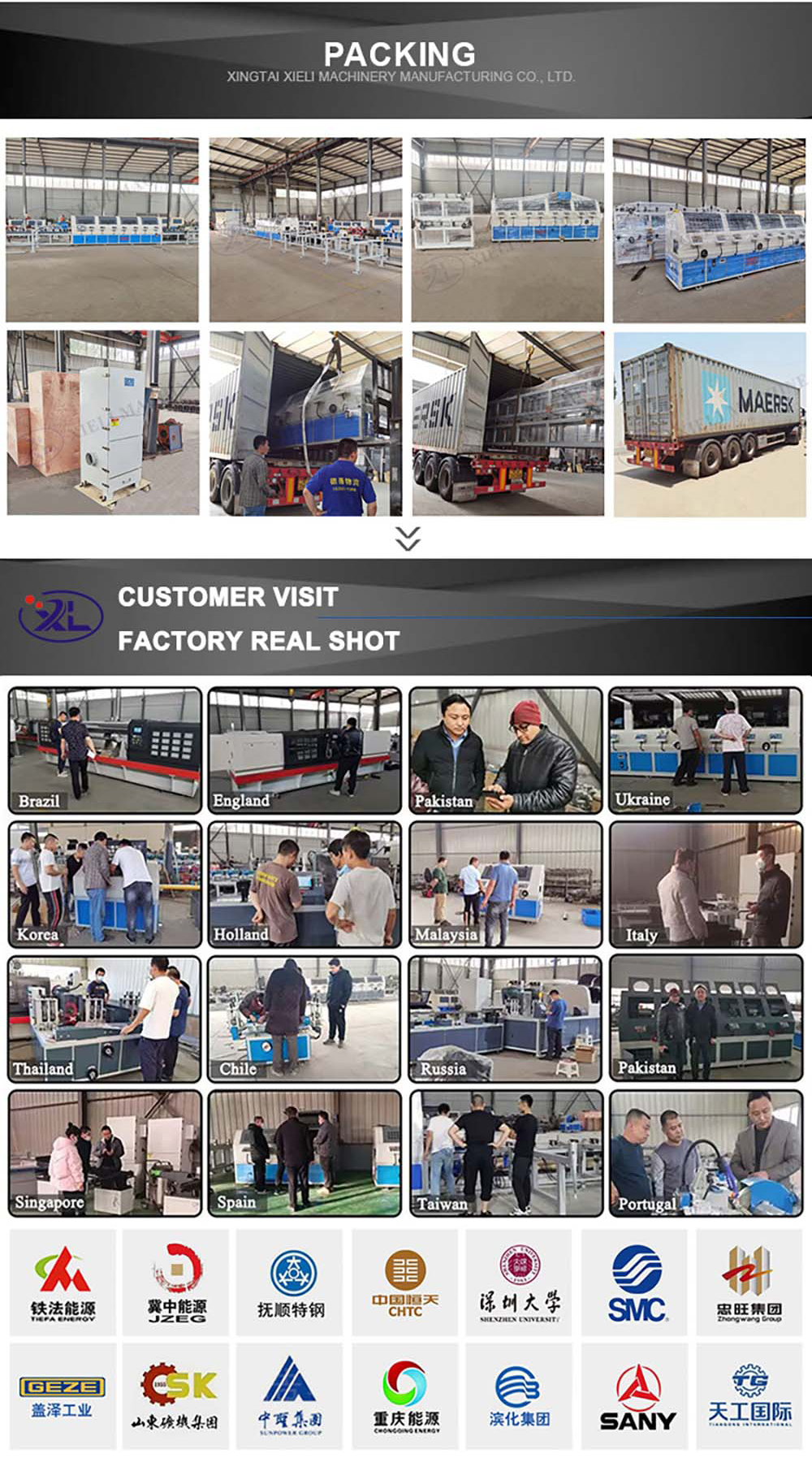

When it comes to selecting a supplier for square pipe polishing machines, there are several criteria to consider to ensure you make an informed decision. First and foremost is the supplier's reputation in the industry. A reliable supplier will have a proven track record of providing high-quality machines and excellent customer service. Reading reviews and testimonials from previous customers can provide valuable insights into a supplier’s reliability and product performance.

square pipe polishing machine supplier

Additionally, it's important to consider the range of products that a supplier offers. A good supplier should provide various models of square pipe polishing machines that cater to different production needs and scales. Whether you require a machine for small batch runs or one capable of high-volume production, the supplier should have options that meet your specific requirements.

Another critical factor is the level of technical support and after-sales service that the supplier can provide. Polishing machines, like any other equipment, may require maintenance or troubleshooting. A supplier that offers robust technical support can significantly minimize downtime and ensure that your operations run smoothly.

Moreover, consider the technological advancement of the machines offered. In an era where efficiency and precision are essential, opting for a supplier that integrates cutting-edge technology into their machines can enhance your production capabilities. Features such as automation, programmable settings, and energy-efficient designs can lead to substantial cost savings and improved productivity.

In conclusion, choosing the right square pipe polishing machine supplier is about more than just purchasing a piece of equipment; it's about partnering with a provider that understands your needs and supports your business goals. By focusing on reputation, product range, technical support, and technology, manufacturers can ensure they invest in a machine that not only meets but exceeds their polishing requirements, ultimately enhancing the quality of their end products.