The Role and Importance of Square Pipe Polishing Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing and metalworking, the quest for precision, efficiency, and aesthetic appeal has led to the development of advanced machinery that streamlines production processes. One such innovation is the square pipe polishing machine, a vital component in the fabrication of square and rectangular pipes used across various industries. This article discusses the functionality, benefits, and applications of square pipe polishing machines, demonstrating their significance in modern manufacturing.

Understanding Square Pipe Polishing Machines

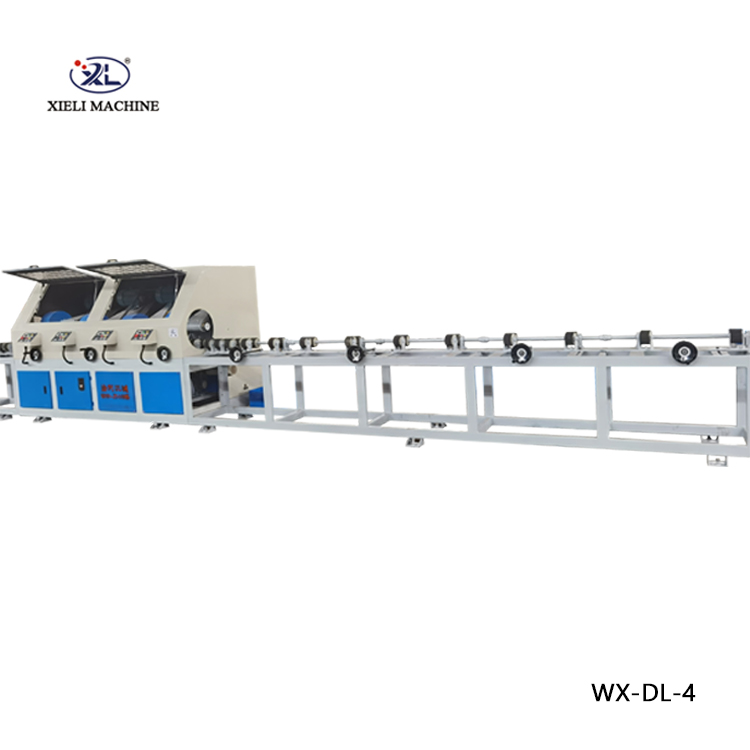

A square pipe polishing machine is designed specifically to refine the surface of square and rectangular pipes, ensuring a smooth, high-quality finish. The machine employs various polishing techniques, such as abrasive belt polishing, buffing, or vibratory finishing, depending on the desired outcome. These machines can handle pipes of different sizes and thicknesses, making them versatile tools in any metalworking shop.

The process begins with the pipe being fed into the machine, where it undergoes surface preparation. This may involve removing weld seams, burrs, and other imperfections that might affect the final finish. After the surface is adequately prepared, polishing pads or belts are utilized to enhance the finish, resulting in a sleek and mirror-like appearance. The polishing process not only enhances aesthetics but also increases the durability and corrosion resistance of the pipes.

Advantages of Using Square Pipe Polishing Machines

1. Enhanced Aesthetics One of the primary benefits of polishing square pipes is the aesthetic appeal. A polished surface is visually striking and can significantly enhance the attractiveness of the finished product. This is particularly important in industries such as architecture and design, where appearance plays a crucial role.

2. Improved Performance The polishing process reduces surface roughness, which can improve the overall performance of the pipes. Smooth surfaces are less likely to harbor contaminants and are easier to clean, making them suitable for applications that require high hygiene standards, such as food processing and pharmaceuticals.

3. Corrosion Resistance Polished surfaces are more resistant to oxidation and corrosion. By eliminating surface imperfections and providing a protective layer, polishing machines help extend the lifespan of metal pipes, reducing the need for frequent replacements and maintenance.

4. Increased Efficiency Modern square pipe polishing machines are equipped with advanced technology that enhances efficiency. Automated systems can handle multiple pipes simultaneously, reducing labor costs and increasing productivity. Tight integration with manufacturing processes ensures that polishing requirements are met without interrupting workflows.

square pipe polishing machine product

5. Customizability Many polishing machines can be customized to accommodate specific project requirements, including different pipe sizes, shapes, and finishes. This adaptability makes them suitable for small batch production as well as large-scale manufacturing.

Applications of Square Pipe Polishing Machines

The versatility of square pipe polishing machines allows them to be utilized in various sectors, including

- Construction and Architecture Polished square pipes are commonly used in structural applications and decorative elements. They are an essential component in railings, columns, and frameworks where both strength and visual appeal are necessary.

- Automotive Industry In automotive manufacturing, polished pipes are used for exhaust systems and structural components that require both durability and aesthetic value.

- Furniture Design The furniture industry often employs square pipes for frames and supports. Polished finishes add elegance, making furniture pieces more appealing to consumers.

- Manufacturing Equipment Many manufacturing applications require polished pipes for hygienic and functional purposes. In food processing plants, for instance, polished surfaces facilitate easier cleaning and maintenance.

Conclusion

Square pipe polishing machines play a crucial role in modern manufacturing, addressing the dual demands of functional performance and aesthetic beauty. Their ability to enhance surface quality, improve corrosion resistance, and increase production efficiency makes them indispensable tools in various industries. As technology continues to evolve, these machines will likely incorporate more sophisticated features, further enhancing their utility and importance in the production of high-quality square pipes. Investing in a reliable square pipe polishing machine is, therefore, a strategic decision for manufacturers aiming to stay competitive in a dynamic market.