Square Pipe Polishing Machine Suppliers in India An Overview

In the ever-evolving manufacturing sector, the need for high-quality finishing processes has gained immense importance. One such vital process is the polishing of square pipes, which are widely used in various industries such as construction, automotive, and furniture. To meet the demand for efficient and effective polishing solutions, several suppliers in India have emerged, offering state-of-the-art square pipe polishing machines. This article explores the significance of these machines, how they function, and highlights some of the prominent suppliers in India.

The Importance of Pipe Polishing

Polishing is essential for square pipes to enhance their aesthetic appeal and prevent corrosion. A well-polished surface not only improves the appearance of the product but also increases its lifespan and durability. In industries where hygiene is crucial, such as food and pharmaceuticals, polished surfaces are easier to clean and less likely to harbor bacteria.

Square pipe polishing machines automate the polishing process, ensuring consistent quality and reducing manual labor. These machines can provide a mirror-like finish that is often required for premium applications. Moreover, advancements in technology have made modern polishing machines faster and more efficient, significantly reducing production time.

How Square Pipe Polishing Machines Work

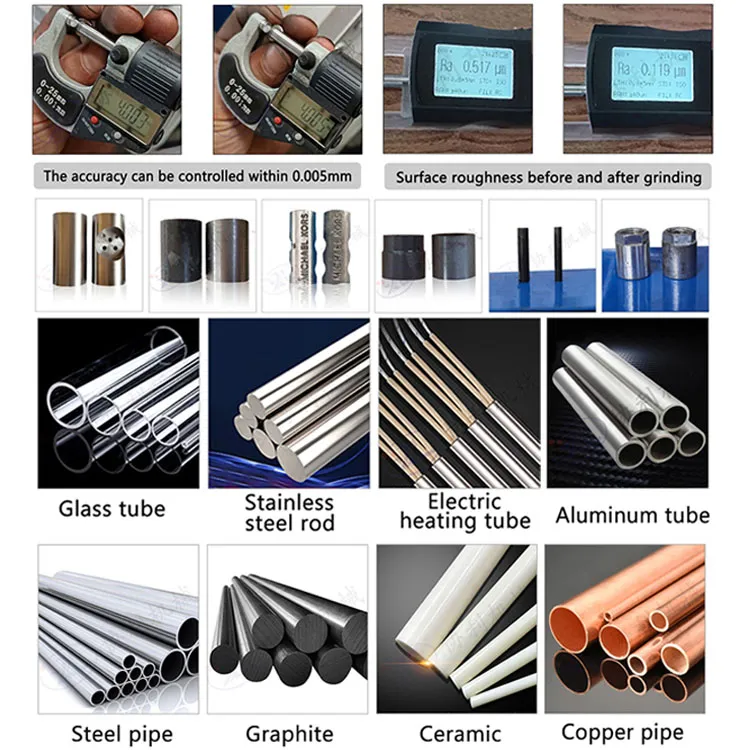

Square pipe polishing machines operate using various techniques, including mechanical polishing, chemical polishing, or electro-polishing. The choice of method depends on the intended use of the pipes and the desired finish.

1. Mechanical Polishing This is the most common method, utilizing abrasives to grind and smooth the surface. The square pipes are mounted on a conveyor, where they pass through a series of polishing heads that progressively refine the surface.

2. Chemical Polishing This method uses chemical solutions to remove a thin layer of metal from the surface of the square pipes, resulting in a smooth finish without mechanical abrasion. It is particularly useful for intricate designs and where precision is key.

3. Electro-Polishing This advanced technique involves subjecting the metal to an electrolytic process that removes imperfections, resulting in a highly polished surface. This method is particularly popular in the food and pharmaceutical industries due to its excellent hygiene standards.

square pipe polishing machine india suppliers

Key Suppliers of Square Pipe Polishing Machines in India

India has a multitude of suppliers specializing in square pipe polishing machines, catering to various industrial needs. Here are some key players in the market

1. Shree G. K. Engineering Works Based in Gujarat, this company is known for its high-quality polishing machines that are designed for efficient performance. Their machines are customizable, catering to specific client requirements.

2. Kothari Group With decades of experience in the industry, Kothari Group offers a range of polishing solutions, including square pipe polishing machines. Their commitment to innovation and quality has made them a prominent name in the Indian market.

3. Gurukrupa Industries Located in Maharashtra, Gurukrupa Industries specializes in manufacturing and exporting polishing machines. They provide end-to-end solutions, including installation and maintenance support, ensuring customer satisfaction.

4. S.K. Engineering Renowned for their focus on research and development, S.K. Engineering offers cutting-edge technology in square pipe polishing machines. Their emphasis on automation helps industries reduce labor costs and improve efficiency.

5. Aastha Enterprises This supplier offers a variety of finishing machines, including specific solutions for square pipe polishing. Their products are known for their durability and ease of use, making them a reliable choice for manufacturers.

Conclusion

The demand for square pipe polishing machines is on the rise in India, driven by the need for higher quality finishes in various applications. With a range of suppliers offering advanced solutions, industries can find machines that meet their specific needs. Equipped with modern technology, these suppliers are helping drive growth in the manufacturing sector, ensuring that Indian products can compete on a global scale. As the market continues to evolve, advancements in polishing technology will undoubtedly play a crucial role in shaping the future of manufacturing processes.