Exploring Square Pipe Polishing Machine Factories

In the realm of manufacturing, the importance of surface finishing cannot be overstated. Among the various techniques utilized for enhancing the quality and aesthetic appeal of metal products, square pipe polishing has emerged as a critical process, particularly in industries such as automotive, construction, and furniture. The demand for high-quality square pipe polishing machines has led to the establishment of numerous specialized factories dedicated to producing these essential tools.

Square pipe polishing machines are designed to ensure that the surfaces of square pipes are smooth and free from imperfections. This is crucial not only for aesthetic reasons but also for preventing corrosion and enhancing the pipe's durability. As a result, factories that focus on manufacturing these machines play a vital role in the supply chain. They are equipped with advanced technology and skilled personnel who understand the intricacies of metal finishing.

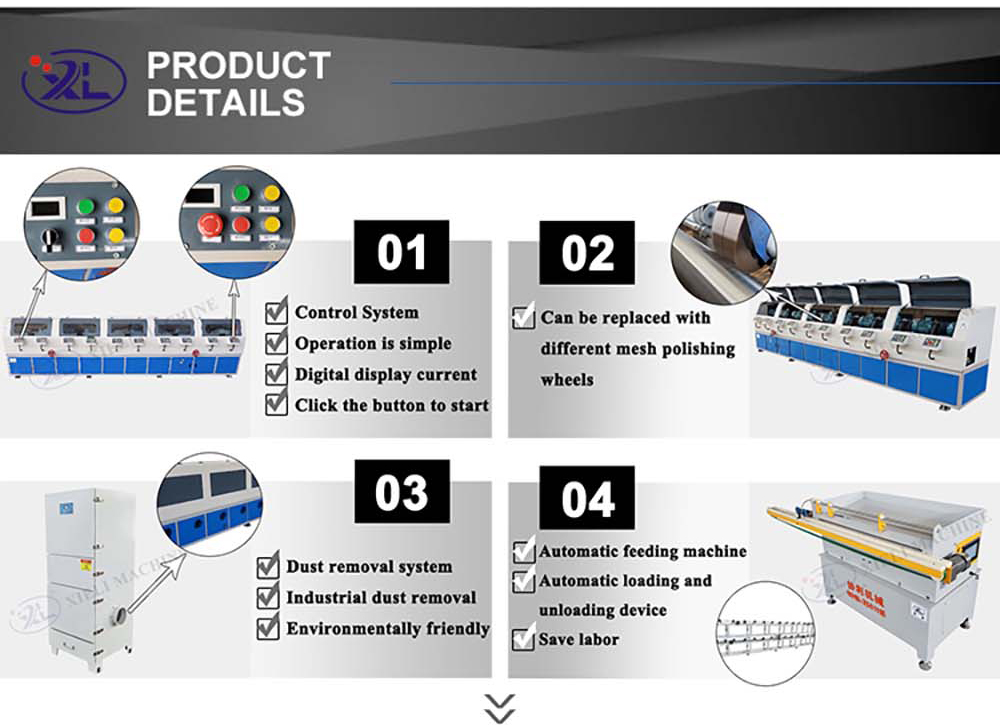

In these factories, various models of square pipe polishing machines are produced, each catering to different requirements. Some machines are designed for small-scale operations, while others are suitable for large industrial applications. The size and complexity of the machine often dictate its cost, maintenance needs, and the volume of work it can handle. For businesses looking to invest in such machinery, understanding the specifications and capabilities of different models is essential.

square pipe polishing machine factories

The manufacturing process in square pipe polishing machine factories involves several stages, including design, engineering, assembly, and quality control. Each stage is crucial to ensure that the final product meets industry standards. Advanced manufacturing techniques such as CNC machining and robotic assembly are often employed to enhance precision and efficiency.

Moreover, environmental sustainability has become a significant consideration for many square pipe polishing machine factories

. Many manufacturers are focusing on eco-friendly practices, such as utilizing water-based polishing compounds and energy-efficient motors, to reduce their ecological footprint.Collaboration with other sectors is also common in this industry. For instance, partnerships with research institutions can lead to innovations in polishing technology, resulting in more effective machines that cater to the evolving needs of the market. Furthermore, international collaborations enable factories to exchange knowledge and improve upon traditional methods, ensuring that local manufacturers remain competitive.

In conclusion, square pipe polishing machine factories play an indispensable role in the manufacturing landscape. As industries continue to seek efficiency and quality, these factories are positioned to meet the evolving demands of their clients, integrating state-of-the-art technology and sustainable practices to produce machines that enhance the metal finishing process. Their contributions not only elevate the quality of manufactured products but also push the boundaries of industrial capabilities forward.