The Rise of SMT Centerless Grinder Exporters

In the ever-evolving landscape of manufacturing, the demand for precision machinery has been on the rise. Among the various types of machinery that meet this demand, centerless grinders, particularly those manufactured by companies in the SMT (Surface Mount Technology) sector, have become increasingly vital. These machines have carved a niche for themselves in the global market, with a significant number of exporters emerging to cater to the diverse needs of industries worldwide.

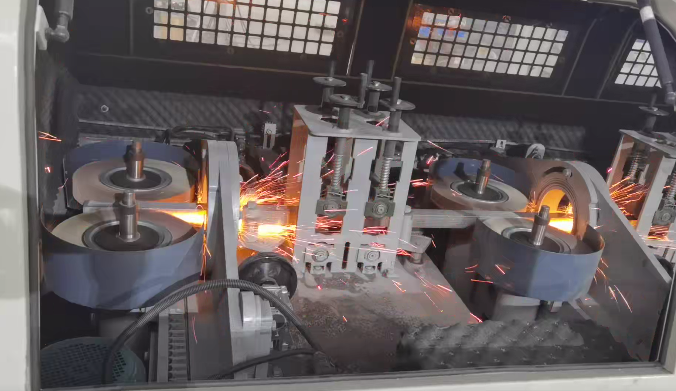

Centerless grinding is a machining process that removes material from the outside diameter of an object. Unlike traditional grinding methods, where the workpiece is supported at both ends, centerless grinding holds the workpiece in place while grinding takes place. This offers several advantages, including higher efficiency, reduced operational costs, and the ability to process large volumes of parts with minimal intervention. For industries requiring high-precision components, SMT centerless grinders are often the equipment of choice.

The Rise of SMT Centerless Grinder Exporters

The SMT sector is known for its innovative technologies and commitment to quality. Exporters in this field are leveraging advanced engineering practices and cutting-edge technology to produce centerless grinders that offer superior performance. These machines often boast features such as improved accuracy, user-friendly interfaces, and robust construction, making them appealing to manufacturers worldwide.

smt centerless grinder exporters

Moreover, SMT centerless grinder exporters are also focused on complying with international quality standards. Many of these companies have obtained certifications such as ISO 9001, which helps them establish credibility and trust among potential buyers. By adhering to strict quality control processes, they ensure that each piece of equipment delivered meets the rigorous demands of modern manufacturing.

The surge in demand for SMT centerless grinders is also driven by the increasing emphasis on automation within manufacturing plants. As companies strive to increase productivity, automated centerless grinders are becoming indispensable. These machines can perform grinding operations with minimal human intervention, thereby reducing labor costs and increasing efficiency. Exporters are responding to this trend by integrating smart technologies into their equipment, allowing users to take advantage of data analytics and machine learning to optimize their processes.

Furthermore, the adaptability of SMT centerless grinders enhances their appeal in various markets. These machines can be configured to handle a wide range of materials, including metals, plastics, and composites. This versatility means that exporters can cater to diverse industries and applications, from producing high-precision automotive components to crafting intricate aerospace parts.

In conclusion, the growth of SMT centerless grinder exporters reflects the broader trends in global manufacturing. As industries continue to seek precision and efficiency in their machining processes, the demand for advanced equipment, such as centerless grinders, will likely continue to rise. By focusing on innovative technologies, quality assurance, and adaptability, these exporters are well-positioned to lead the way in meeting the evolving needs of the manufacturing sector. The future looks bright for those involved in the export of SMT centerless grinders, as they not only enhance production capabilities but also contribute to the overall advancement of manufacturing practices worldwide.