The Rise of SMT Centerless Grinder Companies in Precision Manufacturing

In the rapidly evolving landscape of precision manufacturing, Centerless Grinding has emerged as a pivotal technique, and companies specializing in SMT (Surface Motion Technology) centerless grinders are at the forefront of this innovation. Centerless grinding differs from traditional cylindrical grinding in that it does not require the workpiece to be mounted on a spindle. Instead, the workpiece is held between two grinding wheels, offering remarkable efficiency and precision—traits that are increasingly essential in today’s manufacturing environments.

The Rise of SMT Centerless Grinder Companies in Precision Manufacturing

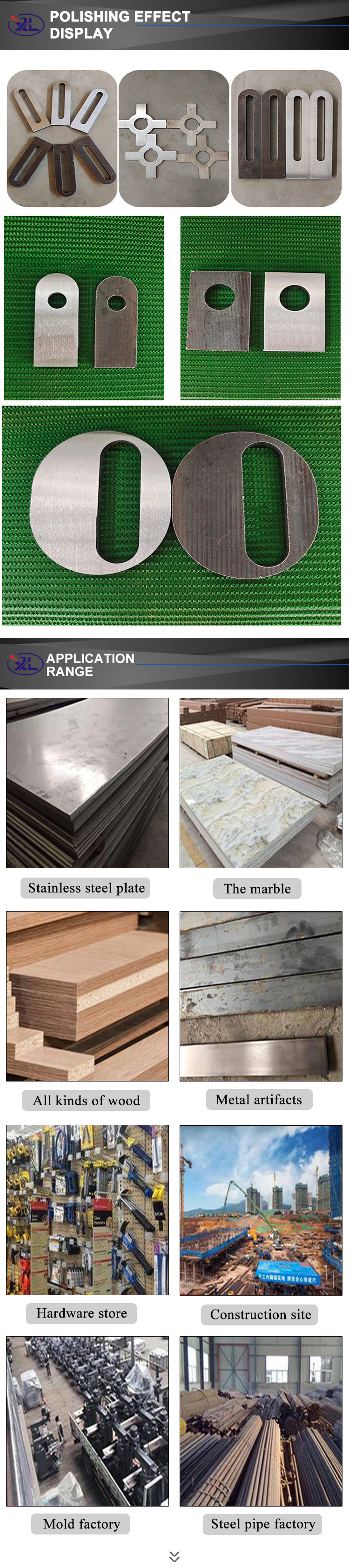

One of the significant advantages of SMT centerless grinders is their ability to accommodate a range of workpiece sizes and shapes, making them extremely versatile. This adaptability is crucial in modern manufacturing, where bespoke solutions are often necessary to remain competitive. Moreover, advancements in technology have led to the development of CNC (Computer Numerical Control) centerless grinders, which offer enhanced automation and precision. This technology allows for the easy monitoring and adjustment of grinding parameters, ensuring consistent quality across large production runs, and minimizing human error.

smt centerless grinder companies

Another factor contributing to the popularity of SMT centerless grinder companies is the focus on sustainability. In an era where environmental concerns are paramount, the efficiency of centerless grinding processes leads to reduced material waste and lower energy consumption compared to traditional methods. This aligns with the broader industry shift towards sustainable manufacturing practices. Companies that adopt these technologies can not only enhance their operational efficiency but also position themselves favorably in a market increasingly driven by sustainability metrics.

Furthermore, SMT centerless grinder companies are investing significantly in research and development to enhance their offerings. Innovations such as improved grinding wheel materials, sophisticated coolant systems, and advanced software solutions have transformed the capabilities of these grinders. The continuous improvement of these technologies ensures that SMT companies remain competitive and can meet the ever-growing demands for precision manufacturing.

In conclusion, SMT centerless grinder companies are playing a vital role in the transformation of the precision manufacturing sector. By providing efficient, versatile, and sustainable solutions to meet the needs of various industries, they are poised to continue their growth trajectory. As manufacturing becomes increasingly advanced, these companies will be essential in delivering the high-quality components necessary for tomorrow's technological innovations. Embracing the benefits of centerless grinding will not only enhance productivity but also contribute significantly to the overall success of manufacturers in a competitive marketplace.