Small Centerless Grinding Machine Company Precision Engineering at Its Best

In the realm of precision manufacturing, small centerless grinding machines have carved out a niche that is essential for producing high-quality components across various industries. A small centerless grinding machine company specializes in designing and manufacturing these sophisticated machines, which are instrumental in enhancing productivity and accuracy in metalworking processes.

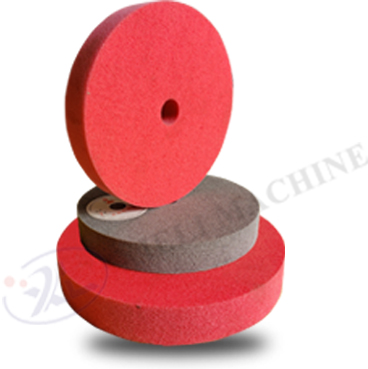

Centerless grinding is a unique machining process that removes material from a workpiece without the need for a fixture or holding device. This distinction allows for continuous workpiece movement, significantly increasing output efficiency. The primary components of a centerless grinding machine include a grinding wheel, a regulating wheel, and a work rest. The workpiece is held between the two wheels, where the grinding wheel removes material while the regulating wheel controls the speed and direction of the workpiece.

One of the standout features of small centerless grinding machines produced by specialized companies is their compact size, which is particularly advantageous for small to medium-sized enterprises (SMEs) with limited floor space. These machines offer high precision and are designed for flexibility, allowing manufacturers to grind various materials, including metals, plastics, and ceramics. Whether it’s for the automotive, aerospace, or medical industries, the reliability and precision of these machines ensure that they meet the stringent quality standards required in modern manufacturing.

small centerless grinding machine company

The technology employed in small centerless grinding machines has evolved dramatically in recent years. Advances in CNC (Computer Numerical Control) systems enable these machines to perform complex grinding operations with minimal human intervention. This not only enhances precision but also reduces the likelihood of human error, leading to consistent output and reduced production costs. Additionally, many companies are increasingly incorporating automation into their machines, allowing for a more streamlined operation and increased throughput.

Collaboration with industry experts is another hallmark of successful small centerless grinding machine companies. By working closely with clients to understand their specific needs, these companies can tailor their machines to suit various applications. They often provide comprehensive support, including training for operators, maintenance services, and technical assistance, ensuring that customers can maximize the efficiency and lifespan of their machines.

Sustainability is also becoming a key focus for modern manufacturing practices, and small centerless grinding machine companies are no exception. Many are adopting eco-friendly practices, utilizing energy-efficient motors and systems that minimize waste, contributing to a greener manufacturing process.

In conclusion, a small centerless grinding machine company plays a pivotal role in the manufacturing sector by providing essential tools that drive efficiency, precision, and quality. As technology continues to advance, these companies are well-positioned to meet the evolving needs of industries worldwide, paving the way for innovative solutions in precision engineering. With their commitment to excellence and adaptability, they are integral to the future of manufacturing.