Small centerless grinding machines have revolutionized many manufacturing processes, bringing precision, efficiency, and cost-effectiveness to industries worldwide. These machines, often underutilized, deserve a more prominent place in conversations about machining and grinding solutions. This article explores the core advantages, technological advancements, and the importance of selecting the right company when investing in a small centerless grinding machine.

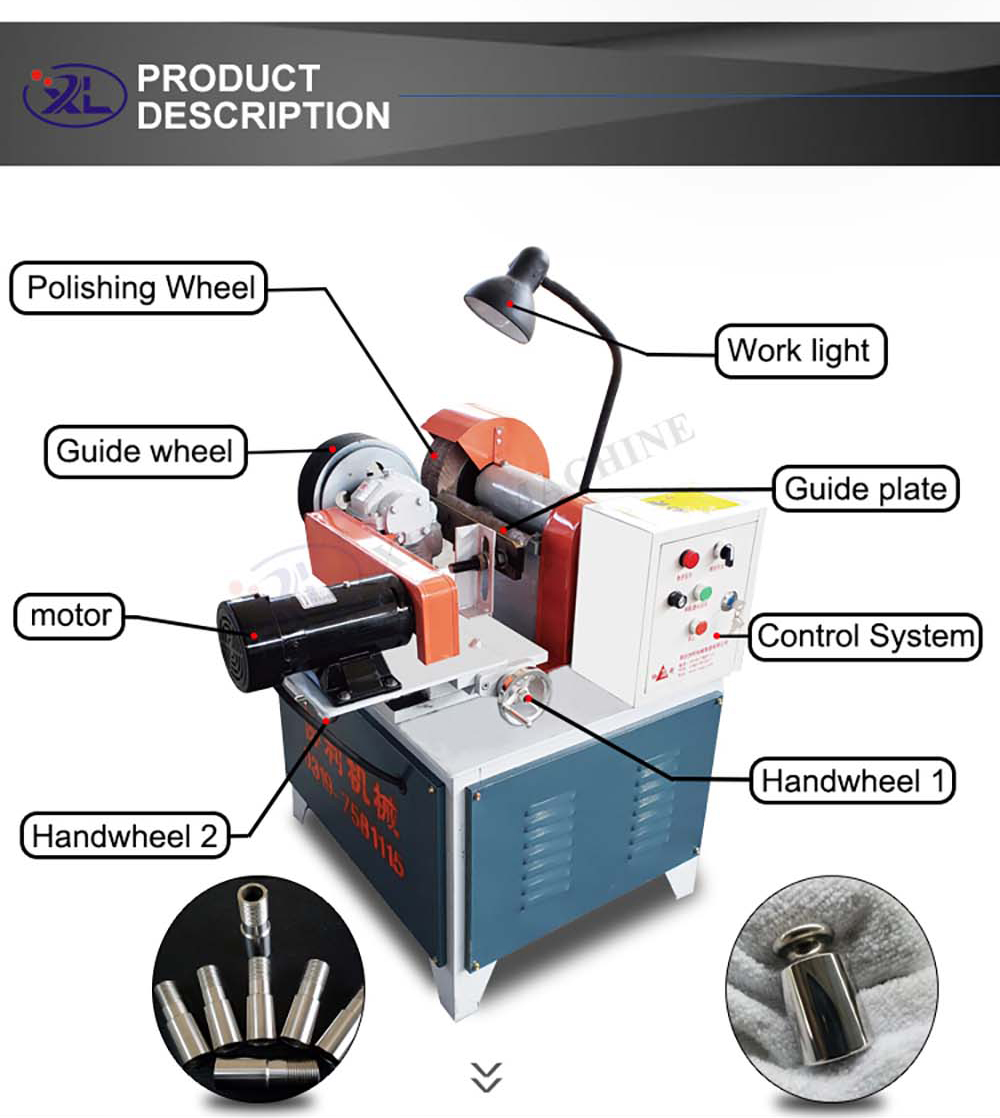

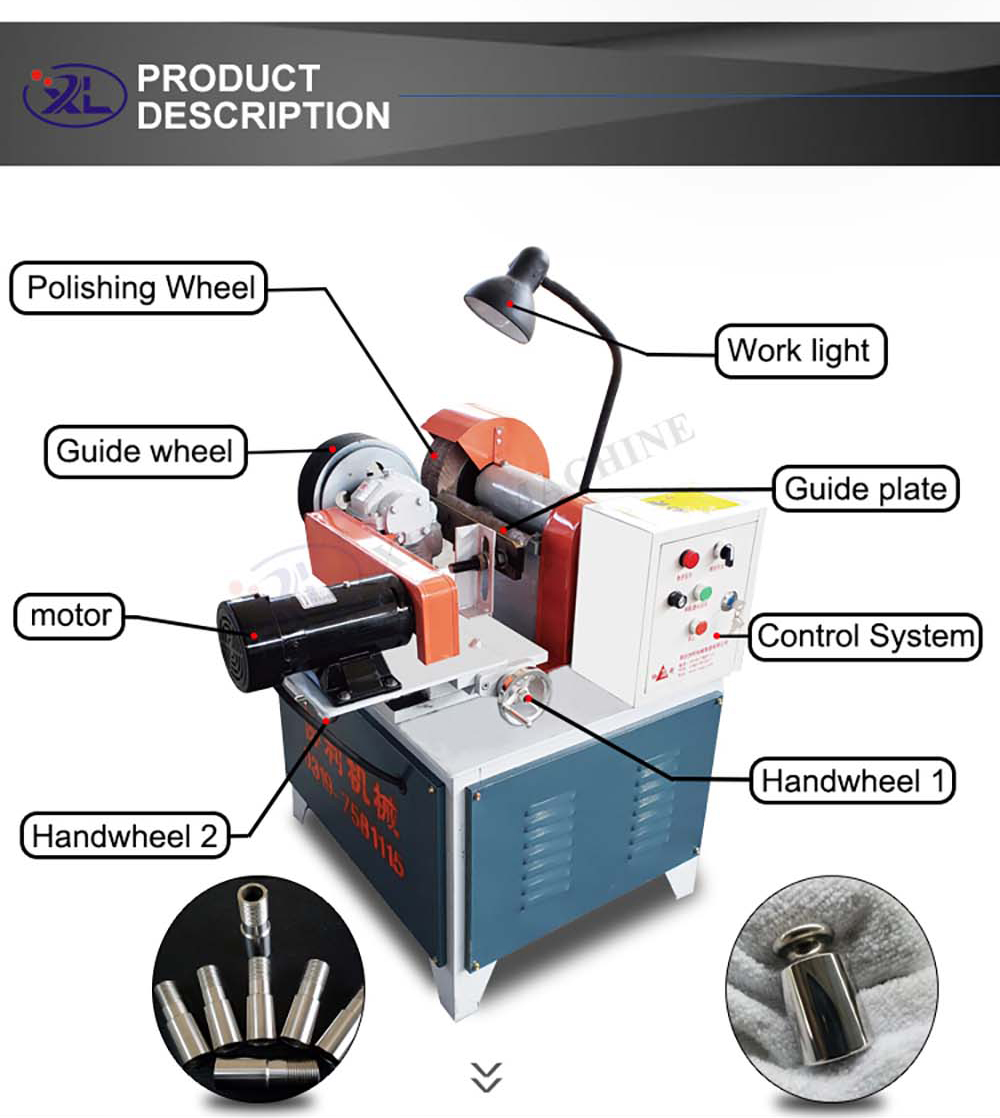

Firstly, we must examine the unique benefits small centerless grinding offers. Unlike traditional grinders, centerless grinders do not require extensive support or workholding devices. This operational advantage results in faster setup times and reduced overhead costs. Small centerless grinding machines, in particular, are compact, making them ideal for facilities with limited space. Their agility does not compromise accuracy, as they are designed to handle high-precision tasks with exceptional dimensional accuracy. This capability is invaluable for industries that demand tight tolerances, such as aerospace, medical devices, and electronics.

However, to truly leverage the potential of small centerless grinding machines, businesses need a thorough understanding of the machine’s capabilities. An experienced company in this niche is essential. A company with a proven track record and a deep understanding of small centerless grinding will provide not just a machine but a comprehensive solution tailored to specific manufacturing needs. They offer insights into optimizing processes, enhancing productivity, and maintaining the machine for longevity. Seek companies that offer extensive training and technical support as these are indicators of a reliable partner committed to your operational success.

The technology behind these machines has evolved significantly.

Modern small centerless grinding machines now incorporate advanced features that enhance performance. Automated systems, for instance, can manage the speed and feed during the grinding process, ensuring consistency and reducing the room for error typically associated with manual intervention. Moreover, some machines come equipped with IoT connectivity, allowing for real-time data monitoring and analytics. This feature enables predictive maintenance, an area critical for avoiding unforeseen downtimes, which can be costly. Consider machines with these technological advancements to future-proof your operations.

small centerless grinding machine company

Authoritativeness in this domain comes from the ability of a company to innovate while maintaining the essence of what makes small centerless grinders effective. Reputable companies often invest in R&D, pushing the boundaries of what these machines can achieve. Certifications and affiliations with industry standards organizations can also indicate a company’s commitment to quality and safety. Experienced manufacturers often publish case studies and white papers, showcasing their ability to handle complex grinding tasks. These publications serve as a testament to their expertise and reliability.

Trustworthiness is another critical factor when selecting a company for small centerless grinding machines. Transparency in communication, ethical business practices, and a commitment to customer satisfaction are non-negotiable traits. Customer testimonials and long-term partnerships with well-known brands can provide insight into a company's reputation. Additionally, warranties and service agreements should clearly outline the company’s responsibilities, ensuring peace of mind regarding maintenance and support.

Investing in a small centerless grinding machine requires a detailed assessment of your manufacturing needs. However, the company you choose plays a pivotal role in the machine’s success and integration into your operations. A company that embodies the values of experience, expertise, authoritativeness, and trustworthiness will not only deliver a machine but also a partnership aimed at elevating your business.

In conclusion, the world of small centerless grinding machines is dynamic and full of potential. By selecting a company that not only understands these machines but also excels in providing comprehensive, tailored solutions, businesses can significantly enhance their manufacturing processes. Balancing cutting-edge technology with market-proven practices ensures that small centerless grinding machines remain an invaluable asset in modern manufacturing.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.