The Rise of Small Centerless Grinder Exporters in the Global Market

In the ever-evolving landscape of manufacturing and precision engineering, small centerless grinders have emerged as pivotal tools for a variety of industries, ranging from automotive to aerospace. These grinders play a crucial role in the production of components that require high precision, tight tolerances, and superior surface finishes. As the demand for precision-engineered parts continues to soar, the exporters of small centerless grinders are experiencing significant growth and recognition on the global stage.

Understanding Centerless Grinding

Centerless grinding is a unique machining process that enables the grinding of cylindrical parts without the need for center holes or fixtures, thus significantly reducing setup time. This process is especially beneficial for producing long, slender workpieces that must maintain high dimensional accuracy. The grinders consist of three main components the grinding wheel, the regulating wheel, and the work rest. The innovation of centerless grinding technology has allowed manufacturers to streamline their operations, reduce costs, and improve productivity.

The Global Market for Small Centerless Grinders

As industries across the globe strive for enhanced productivity and efficiency, the demand for small centerless grinders has surged. The portability and compact design of these machines make them ideal for small to medium-sized enterprises (SMEs) that require precision machining without the need for large, cumbersome equipment. The export market for small centerless grinders has thrived, with exporters capitalizing on the growing need for advanced manufacturing solutions.

The factors driving this growth include increased automation in manufacturing processes, the need for high-quality finished products, and advancements in grinding technology. Exporters are not only focused on supplying machines but also providing comprehensive support services, including training, maintenance, and customization to cater to specific industry needs.

Key Players in the Export Market

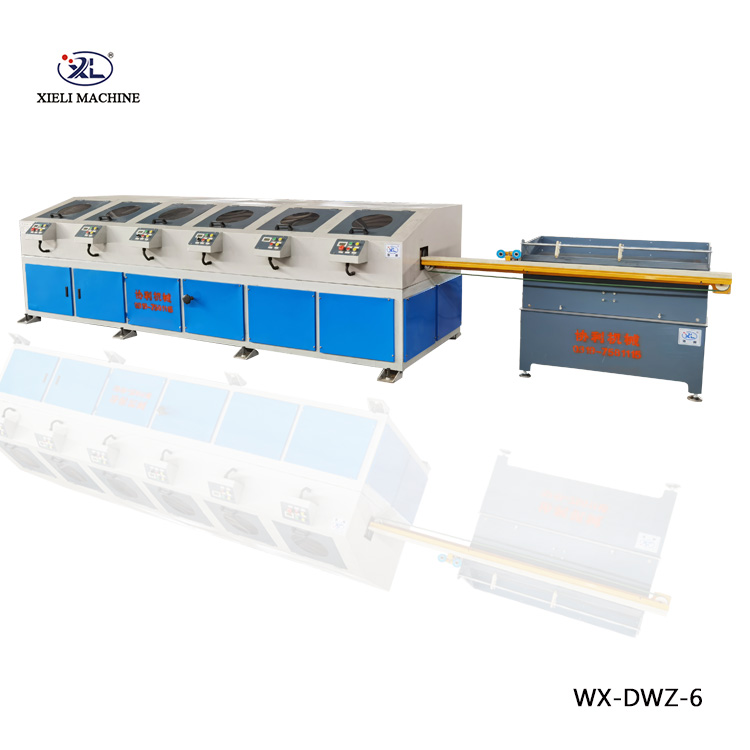

small centerless grinder exporter

The small centerless grinder exporter landscape includes a mix of established manufacturers and newer entrants that are quickly gaining traction. Renowned companies have positioned themselves as leaders in the sector by investing in research and development, thereby continuously improving their product offerings. These key players focus on delivering high-quality grinders that incorporate the latest technological advancements, such as CNC controls, enhanced ergonomics, and energy-efficient designs.

In addition to technological innovations, customer service plays a critical role in the competitiveness of small centerless grinder exporters. By providing responsive support and tailored solutions, these companies foster long-term relationships with their clients and enhance customer satisfaction.

Challenges and Opportunities

Despite the promising growth of the small centerless grinder export market, exporters face several challenges. Intense competition and fluctuating raw material prices can impact profitability. Additionally, geopolitical tensions and trade regulations may pose hurdles for exporters seeking to penetrate new markets.

However, these challenges also present opportunities for innovation and adaptation. Exporters that can leverage technology to improve productivity, enhance product quality, and optimize supply chain logistics will likely emerge as leaders in the market. Furthermore, as sustainability becomes increasingly important, the development of energy-efficient machines and eco-friendly manufacturing practices will resonate well with environmentally conscious consumers.

Conclusion

The small centerless grinder export market is on an upward trajectory, fueled by the rising demand for precision-engineered components across various industries. As global manufacturers seek efficient and reliable solutions for their machining needs, exporters of small centerless grinders stand poised to capitalize on this trend. By embracing innovation, prioritizing customer satisfaction, and navigating the challenges of the global market, these exporters are not only contributing to the manufacturing landscape but also playing a crucial role in the advancement of technology and efficiency in production processes.