A Comprehensive Guide to Sheet Metal Polishing Machines Pricing and Options

In the modern manufacturing landscape, sheet metal polishing machines play a pivotal role in producing high-quality finishes on various metal surfaces. From automotive parts to decorative applications, these machines are essential for achieving the desired aesthetic and functional properties of sheet metal components.

When considering a sheet metal polishing machine, one of the first factors to evaluate is the pricing. Prices can vary widely based on several factors, including the machine's specifications, brand reputation, and additional features. On average, these machines can range from as low as $2,000 for smaller, entry-level models to upwards of $30,000 for industrial-grade machines with advanced capabilities.

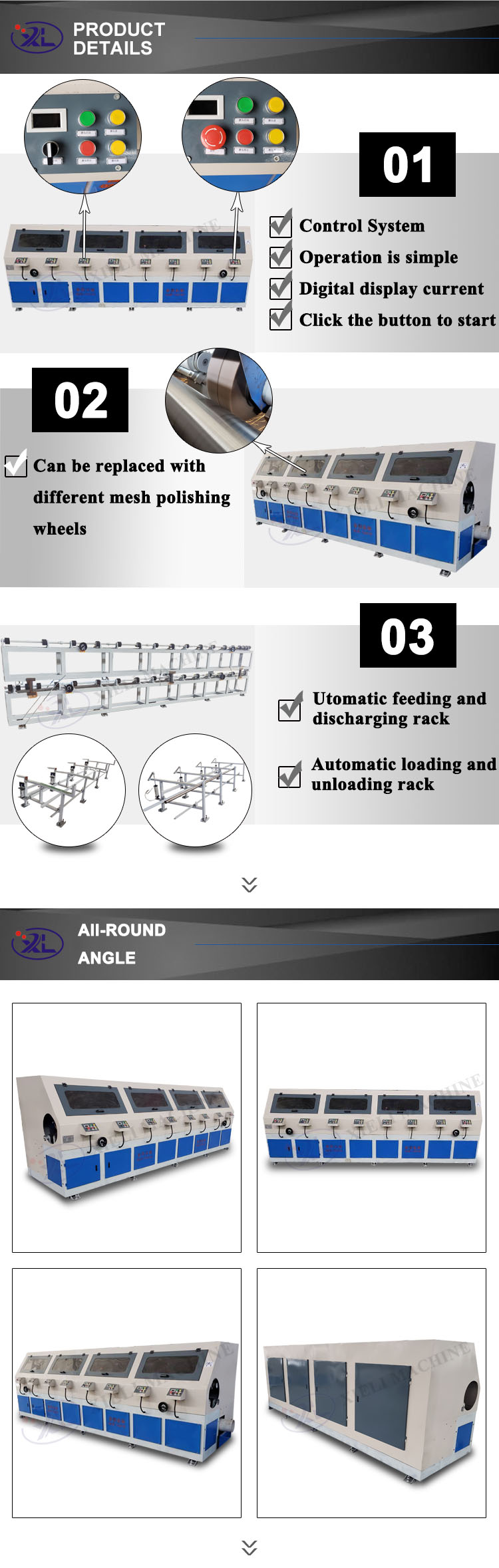

Types of Sheet Metal Polishing Machines

1. Belt Polishers These machines use abrasive belts to polish the surface of sheet metal. They are efficient for surface finishing and can eliminate scratches and imperfections. Pricing typically starts around $3,000.

2. Disc Polishers Utilizing circular discs, these machines are effective for both flat and contoured surfaces. They provide versatility and are ideal for shops that handle a variety of shape and size requirements. Prices range from $5,000 to $15,000.

sheet metal polishing machine pricelist

3. Cylindrical Polishers Designed specifically for cylindrical components, these machines ensure a uniform finish across the surface. Their robust design usually places them in the higher price bracket, often exceeding $10,000.

4. Robotic Polishers Incorporating automation, robotic polishing machines offer precision and speed. They can be programmed for specific tasks, making them suitable for high-volume production. Prices for these advanced systems can start at $20,000 and go significantly higher depending on capabilities.

Budget Considerations

When budgeting for a polishing machine, it’s crucial to consider not only the purchase price but also the potential operational costs, such as maintenance, tooling, and energy consumption. Investing in a higher-quality machine may yield long-term savings by reducing downtime and improving production efficiency.

Conclusion

In conclusion, the price range for sheet metal polishing machines reflects the diversity of options available to manufacturers. Whether you are a small workshop or a large production facility, understanding your needs and aligning them with the right machine is essential for enhancing productivity and finishing quality. By carefully evaluating the specifications and costs, you can make an informed decision that will benefit your operations for years to come.