The Importance of Sheet Metal Polishing Machines A Guide to Manufacturers

In the realm of manufacturing and metalworking, sheet metal polishing plays a crucial role in enhancing the aesthetic appeal and functional quality of products. As industries demand higher standards of finish and durability, the need for advanced sheet metal polishing machines has surged. This article delves into the significance of these machines, the role of manufacturers, and the innovations shaping the future of metal polishing.

Understanding Sheet Metal Polishing

Sheet metal polishing involves the use of abrasive materials and techniques to smooth the surface of metal sheets. This process not only improves the visual appeal of the products but also contributes to corrosion resistance and prepares surfaces for further treatments, such as painting or coating. Industries ranging from automotive to aerospace rely heavily on polished metal sheets to meet their quality standards.

The Role of Manufacturers

Manufacturers of sheet metal polishing machines play a pivotal role in the production process. They design and produce machines that can handle a variety of sheet metal types and thicknesses, catering to both small workshops and large industrial installations. The effectiveness of a polishing machine greatly influences the final product's quality, making the choice of manufacturer an essential consideration for businesses.

1. Innovation and Technology Leading manufacturers invest in research and development to create machines that incorporate the latest technologies. Features such as automatic feeding systems, adjustable polishing heads, and programmable controls are becoming increasingly common. These advancements not only enhance the efficiency of the polishing process but also improve the consistency and quality of the finish.

2. Customization Different industries have varying requirements when it comes to polishing. Top manufacturers offer customizable solutions, allowing businesses to specify their needs, whether it involves specific polishing grades, machine sizes, or additional features. This tailored approach ensures that businesses can achieve their desired outcomes without compromising on efficiency or quality.

3. Support and Service The relationship between manufacturers and their clients does not end with the sale of a machine. Reliable manufacturers provide ongoing support, including maintenance services and training for operators. This support is crucial for ensuring that machines operate at peak efficiency and that workers are skilled in using the equipment effectively.

Selecting the Right Manufacturer

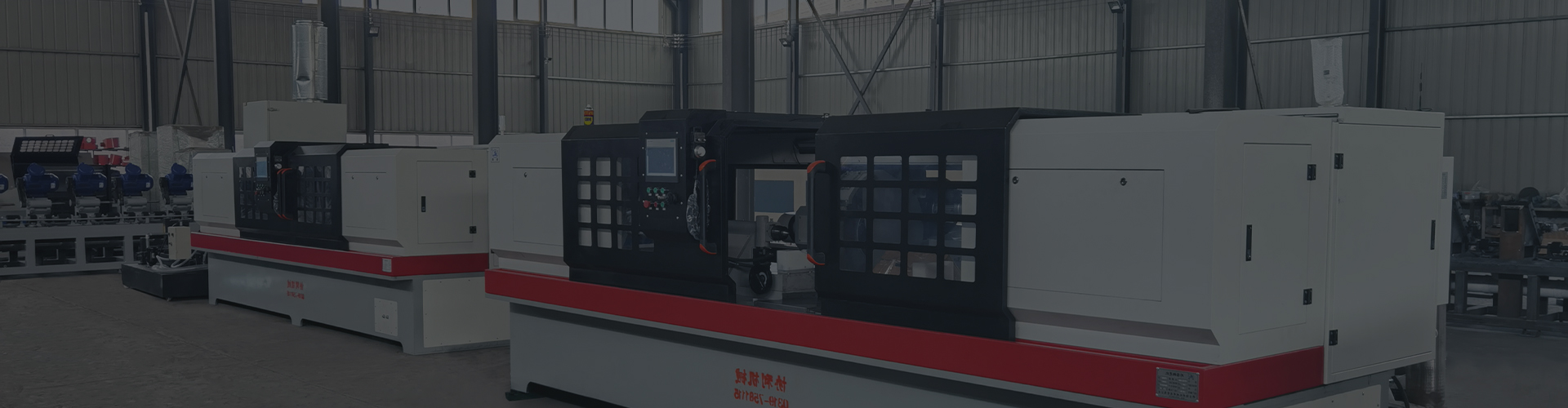

sheet metal polishing machine manufacturer

Choosing the right sheet metal polishing machine manufacturer is critical for businesses seeking quality and efficiency. Here are a few factors to consider

- Reputation Researching a manufacturer's reputation within the industry can provide insights into their reliability and product quality. Reviews, testimonials, and case studies can offer valuable information about their capabilities.

- Product Range A manufacturer that offers a wide range of machines is advantageous as it indicates their experience and expertise. Businesses should look for manufacturers that can provide machines suitable for their specific polishing needs.

- Technology and Innovation As technology rapidly evolves, manufacturers that keep pace with innovations are more likely to provide efficient and effective solutions. Staying updated with the latest trends in the industry can help businesses select machines that will not become obsolete quickly.

- Customer Support Excellent customer support is a hallmark of a reputable manufacturer. Ensure that they offer training, maintenance, and quick response times for any issues that may arise during operation.

Future Trends in Sheet Metal Polishing

The world of sheet metal polishing is continuously evolving. With the rise of automation and artificial intelligence, future polishing machines are expected to integrate smart technologies, making the polishing process more efficient and accurate. The incorporation of environmentally friendly polishing solutions and materials is also on the rise, reflecting the industry's shift towards sustainability.

Conclusion

In conclusion, sheet metal polishing machines are vital components of modern manufacturing. The role of manufacturers in producing high-quality, innovative machines cannot be overstated. As the demand for polished metal continues to grow across various industries, selecting the right manufacturer will be crucial for businesses aiming to enhance the quality and appeal of their products. A focus on technology, customization, and exceptional customer service will undoubtedly lead to a more efficient and productive polishing process, paving the way for future advancements in sheet metal processing.