The Growing Demand for Sand Belt Polishing Machines and Key Exporters

In recent years, the manufacturing and industrial sectors have witnessed a significant increase in the demand for sand belt polishing machines. These versatile machines play a crucial role in surface finishing, helping industries achieve a polished and refined look for a variety of materials, including metals, wood, and plastics. As globalization continues to shape trade, the export market for sand belt polishing machines has expanded, with several key exporters leading the way.

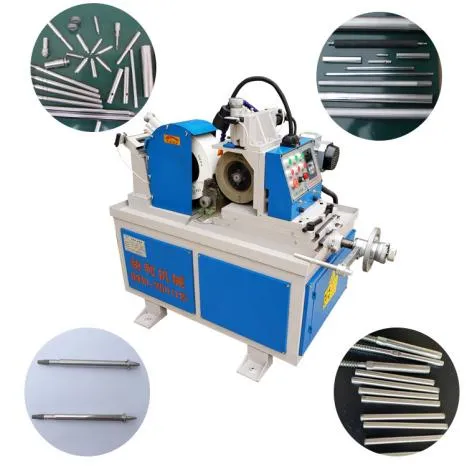

Sand belt polishing machines are essential for achieving high-quality finishes on products. They utilize abrasive belts to smooth surfaces and eliminate imperfections, which is particularly important in industries that prioritize aesthetics and precision, such as automotive, aerospace, and furniture manufacturing. The ability to customize these machines for different applications is a significant advantage, making them a valuable investment for manufacturers worldwide.

Several countries stand out as major exporters of sand belt polishing machines. Among them, countries with advanced manufacturing capabilities, like Germany, Italy, and the United States, are prominent players in the market. These nations are known for their engineering excellence and innovative designs, producing machines that are not only efficient but also reliable. German manufacturers, in particular, are renowned for their high-quality engineering standards and robust machines that often come with advanced technology and features.

sand belt polishing machine exporters

Italy is another key player in the sand belt polishing machine export market. The Italian design and engineering expertise have led to the development of aesthetically appealing and user-friendly machines, which are highly sought after by international buyers. The country’s rich tradition in craftsmanship, particularly in woodworking and metalworking, has fostered a culture of innovation in surface finishing technology.

The United States also contributes significantly to the export of sand belt polishing machines. Its manufacturers leverage cutting-edge technology and automation, focusing on creating high-performance machines that cater to diverse industrial needs. American exporters often emphasize customization, providing tailored solutions that meet the specific requirements of their clients.

In addition to these traditional exporters, emerging markets in Asia, particularly China and India, have also become significant players in the sand belt polishing machine industry. These countries are rapidly expanding their manufacturing capabilities and are producing machines that often offer competitive pricing, making them attractive to buyers looking for cost-effective solutions.

As the global market continues to evolve, the importance of sand belt polishing machines cannot be overstated. Their role in enhancing product quality and ensuring high standards of finish will remain paramount. For those looking to invest in such equipment, understanding the landscape of exporters is crucial to making informed purchasing decisions. In conclusion, the demand for sand belt polishing machines is on the rise, and the market is poised for further growth as industries seek to improve their production processes.