Round Tube Polishing Machine Enhancing Metal Finishing Efficiency

In the world of metal fabrication, the finish of products often makes a significant difference in both aesthetics and functionality. Among the various processes available to enhance the surface of metal materials, polishing stands out as a critical step, especially for round tubes. This is where round tube polishing machines come into play, providing an efficient solution for achieving high-quality finishes on cylindrical metal products.

What is a Round Tube Polishing Machine?

A round tube polishing machine is specialized equipment designed to smooth and polish the surfaces of cylindrical metal tubes. These machines can handle a variety of materials, including stainless steel, aluminum, copper, and other metals, making them versatile tools in any metalworking shop. The primary purpose of these machines is to remove imperfections and achieve a reflective, attractive surface finish.

Types of Round Tube Polishing Machines

There are several types of machines designed for this purpose, each catering to different finishing requirements and production scales

1. Manual Polishing Machines These machines require skilled operators to guide the tubes through polishing equipment. While labor-intensive, they offer flexibility for small batches and specialized finishes.

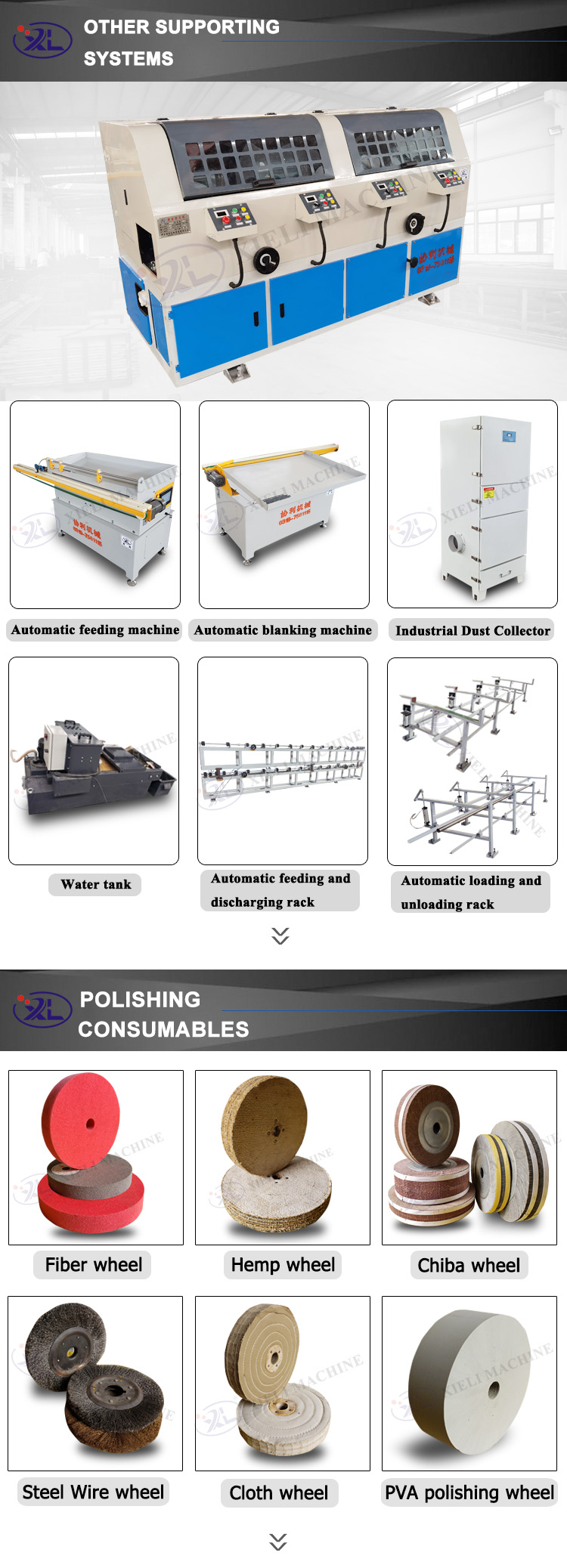

2. Semi-Automatic Machines These machines combine manual operations with automatic functions, allowing for increased efficiency while still enabling operators to manage specific tasks, such as loading and unloading.

3. Fully Automatic Polishing Machines Designed for high-volume production, these machines automate the entire polishing process, reducing labor costs and minimizing human error. They are equipped with advanced technology to ensure consistent quality across all products.

round tube polishing machine

4. CNC Polishing Machines Computer Numerical Control (CNC) polishing machines offer precise control over the polishing process, allowing for intricate designs and uniform finishes. These machines are ideal for manufacturers looking to create complex shapes or require high tolerances.

Benefits of Using Round Tube Polishing Machines

The advantages of investing in a round tube polishing machine are manifold

- Improved Aesthetics Polished tubes exhibit a sleek, professional appearance, which can significantly enhance the visual appeal of finished products. This is crucial for applications where aesthetics matter, such as in architecture, automotive design, and consumer goods.

- Enhanced Corrosion Resistance A polished surface is less prone to corrosion, extending the lifespan of metal components. This is particularly important in industries that expose products to harsh environments.

- Reduced Surface Roughness The polishing process effectively minimizes surface roughness, contributing to better performance in applications that require smoothness, such as fluid flow or assembly with other components.

- Increased Market Value Products with a superior finish often command higher prices in the market. Investing in polishing equipment allows manufacturers to elevate their product offerings, potentially leading to higher profit margins.

Conclusion

Round tube polishing machines are indispensable tools in the metal fabrication industry, offering significant advantages in efficiency, quality, and aesthetic appeal. Whether through manual, semi-automatic, or fully automatic systems, these machines streamline the polishing process, enabling businesses to meet the demands of their customers effectively. As industries continue to evolve, the importance of high-quality finishes will persist, making the investment in advanced polishing technology not just beneficial but essential for competitiveness in the market. By adopting these machines, manufacturers can ensure they deliver superior products that satisfy both functional and aesthetic requirements.