The Significance of Round Pipe Polishing Machines A Comprehensive Overview for Manufacturers

In the ever-evolving landscape of industrial manufacturing, precision and quality have become paramount. Among the various processes that contribute to the overall quality of metal products, polishing plays a crucial role, especially when it comes to round pipes. As industries like construction, automotive, and manufacturing continue to grow, the demand for high-quality round pipe polishing machines is on the rise. In this article, we will explore the significance of these machines, key features to look for when selecting a manufacturer, and the impact of advanced polishing technology on various industries.

Understanding Round Pipe Polishing Machines

Round pipe polishing machines are specialized equipment designed to enhance the surface finish of round pipes made from various materials, including stainless steel, aluminum, and other alloys. The primary goal of these machines is to remove imperfections such as scratches, burrs, and oxidation, resulting in a smooth, aesthetically pleasing surface. A polished surface not only improves the appearance of the metal but also plays a vital role in preventing corrosion and extending the lifespan of the pipe.

Advantages of Using Round Pipe Polishing Machines

1. Enhanced Surface Finish The primary advantage of using a polishing machine is the significant improvement in surface finish. A smooth surface can reduce friction, leading to more efficient flow in applications like plumbing and hydraulics.

2. Time Efficiency Manual polishing can be labor-intensive and time-consuming. Round pipe polishing machines streamline this process, allowing for higher productivity and quicker turnaround times.

3. Consistency Automated polishing machines ensure uniformity in the polishing process, minimizing the variability that can occur with manual labor. This consistency is particularly important in industries where specifications must be adhered to strictly.

4. Cost-Effectiveness Though the initial investment in a polishing machine may be significant, the long-term savings associated with reduced labor costs and minimized material waste can make it a worthwhile investment.

Choosing the Right Manufacturer

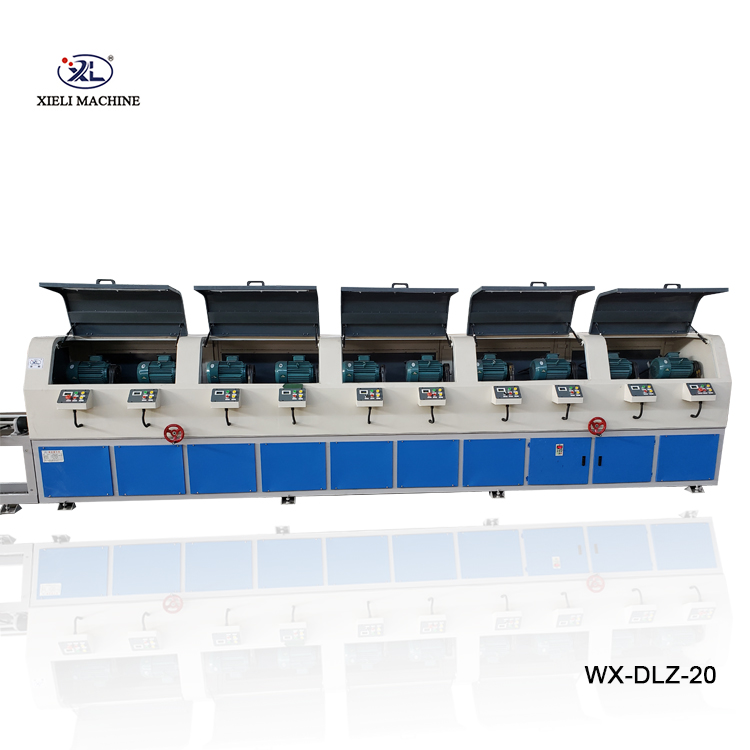

round pipe polishing machine manufacturer

When selecting a manufacturer for round pipe polishing machines, several factors should be considered

1. Experience and Reputation Look for manufacturers with a proven track record in producing high-quality polishing equipment. Industry reputation and years of experience can be indicators of reliability.

2. Technology and Innovation The best manufacturers invest in research and development to incorporate the latest technology into their machines. Features such as automated controls, advanced abrasives, and user-friendly interfaces can enhance the efficiency and effectiveness of polishing.

3. Customer Support and Service A manufacturer that offers strong customer support and after-sales service can significantly enhance your experience. This includes maintenance, repairs, and readily available spare parts.

4. Customization Options Depending on specific manufacturing needs, it may be beneficial to partner with a manufacturer that offers customization options for their polishing machines.

5. Reviews and Testimonials Seeking feedback from existing customers can provide valuable insights into the machine’s performance and the manufacturer’s customer service quality.

The Future of Pipe Polishing Technology

As technology continues to advance, the future of round pipe polishing machines looks promising. Innovations such as robotic polishing, smart automation, and integration with Industry 4.0 practices are transforming the way polishing is performed. These technologies not only enhance efficiency but also provide real-time data analytics, allowing manufacturers to optimize their operations further.

Conclusion

The importance of round pipe polishing machines cannot be overstated in a world that demands high quality and precision in metal fabrication. As industries continue to grow and evolve, selecting the right manufacturer can make all the difference in achieving superior results. By focusing on quality, innovation, and customer support, manufacturers can ensure they are investing in machines that will enhance their production capabilities, resulting in increased customer satisfaction and business success. In an era where surface finish can define the quality of a product, round pipe polishing machines will remain an indispensable asset in the manufacturing sector.