Round Tube Polishing Machine Enhancing Surface Finish with Precision

In the world of metalworking, achieving a flawless finish on round tubes is vital for both aesthetic appeal and functional performance. This is where a round tube polishing machine comes into play, revolutionizing the way manufacturers enhance tube surfaces. These machines are specifically designed to polish round tubes, providing an effective solution for various industries, including automotive, aerospace, and construction.

A round tube polishing machine operates by utilizing advanced technologies and techniques to smooth out imperfections on the surface of tubular materials. Equipped with rotating brushes, abrasive pads, and polishing compounds, these machines work efficiently to remove scratches, oxidation, and unwanted burrs. The result is a high-quality finish that not only enhances the visual appeal of the tubes but also improves their resistance to corrosion and wear.

One of the standout features of modern round tube polishing machines is their automation. Utilizing programmable logic controllers (PLC), these machines can be customized to meet specific polishing requirements. This automation not only speeds up the polishing process but also ensures consistent results across multiple batches. Operators can set parameters such as speed, pressure, and duration, enabling high precision and repeatability, which is essential for maintaining quality standards in production.

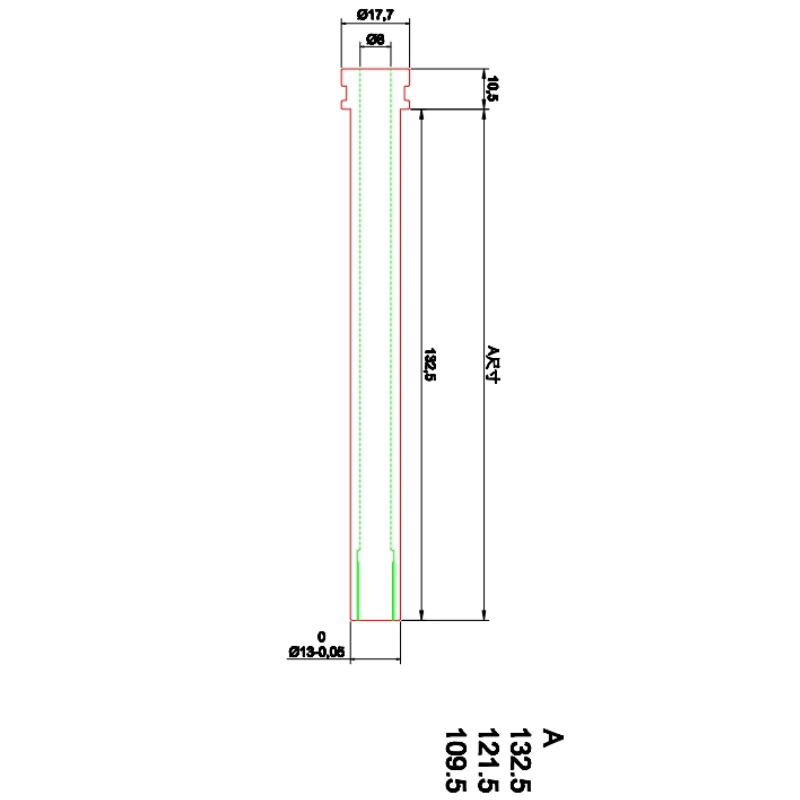

round tube polishing machine product

Moreover, round tube polishing machines come in various models, catering to different sizes and types of tubes. Whether dealing with large industrial pipes or smaller decorative tubes, there’s a machine tailored to fit the job. Some machines even accommodate different materials such as stainless steel, aluminum, and brass, making them versatile tools in any metal fabrication shop.

Furthermore, investing in a round tube polishing machine can enhance operational efficiency by minimizing labor costs and reducing manual polishing efforts. With the ability to process multiple tubes simultaneously, manufacturers can significantly increase productivity without compromising on quality.

In conclusion, the round tube polishing machine stands out as an essential tool for any industry that requires high-quality finished tubes. Its ability to deliver consistent, high-quality polishing combined with advanced technology and automation makes it a valuable asset for enhancing surface finishes. As industries continue to evolve, the importance of having reliable processing equipment like round tube polishing machines will only grow, solidifying their role in the future of metalworking.