Service Overview for Rossi Monza 4 Centerless Grinder

The Rossi Monza 4 Centerless Grinder is a premier machine used in various industries for precision grinding tasks. Its design, which combines efficiency and accuracy, has earned it a reputation among manufacturers who require high-performance equipment. However, like all sophisticated machinery, the Rossi Monza 4 requires regular maintenance and servicing to ensure optimal performance and longevity. This article outlines the key aspects of servicing the Rossi Monza 4 Centerless Grinder.

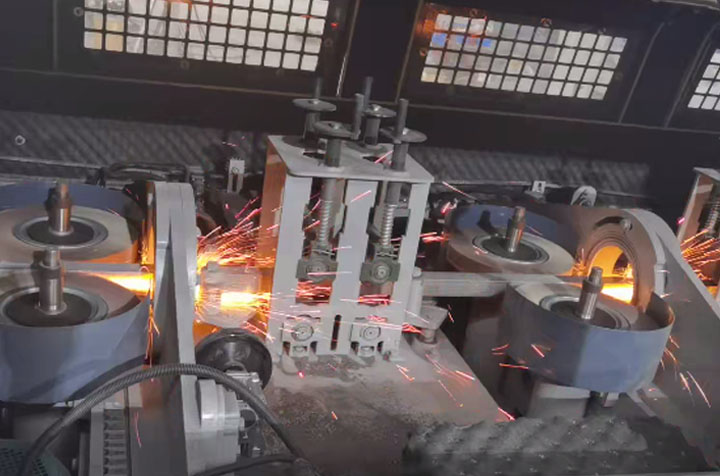

First and foremost, understanding the operation and components of the Rossi Monza 4 is crucial for effective service. The grinder typically consists of three main components the grinding wheel, the regulating wheel, and the workpiece support. Over time, wear and tear on these parts can lead to performance issues, such as reduced grinding accuracy or increased vibration. Regular inspections will help identify such problems early.

Routine maintenance should include checking and adjusting the grinding and regulating wheel alignment. Proper alignment is essential for achieving the desired finish and tolerances on the workpieces. Additionally, the wheels should be dressed regularly to ensure that they maintain a sharp cutting edge, which is vital for efficient grinding.

rossi monza 4 centerless grinder service

Lubrication is another critical aspect of servicing the Rossi Monza 4. Regularly inspecting and replacing lubricants in the machine’s moving parts can significantly reduce friction and wear, leading to improved operational efficiency. It is advisable to consult the manufacturer’s guidelines for lubrication intervals and types of grease or oil to use, as proper lubrication will enhance the lifespan of the grinder.

Furthermore, operators should maintain a clean working environment and ensure that debris and metal shavings do not accumulate around the machine

. A clean workspace not only prolongs the life of the grinder but also promotes safety for the operators.Lastly, it is important to utilize the services of qualified technicians for more extensive repairs and overhauls. Professional service providers have the necessary experience and tools to address complex issues that may arise, ensuring that the Rossi Monza 4 remains in optimal condition.

In summary, regular maintenance and servicing are essential for the efficient operation of the Rossi Monza 4 Centerless Grinder. By following best practices in inspection, lubrication, and cleanliness, operators can ensure that their grinder continues to deliver high-quality performance, meeting the demands of precision grinding in today’s competitive manufacturing environment.