In the modern industrial landscape, surface treatment plays a pivotal role in determining the quality, durability, and market readiness of metal components. Whether in manufacturing plants, fabrication workshops, or specialized facilities, the demand for smooth, high-luster stainless steel surfaces has skyrocketed. As industries grow more sophisticated, so too does the equipment they require. This is where stainless steel sheet polishing machine manufacturers step in, offering cutting-edge solutions that combine automation, precision, and productivity to meet diverse industrial requirements.

Performance Advantages of Integrating a Stainless Steel Plate Polishing Machine in Fabrication Lines

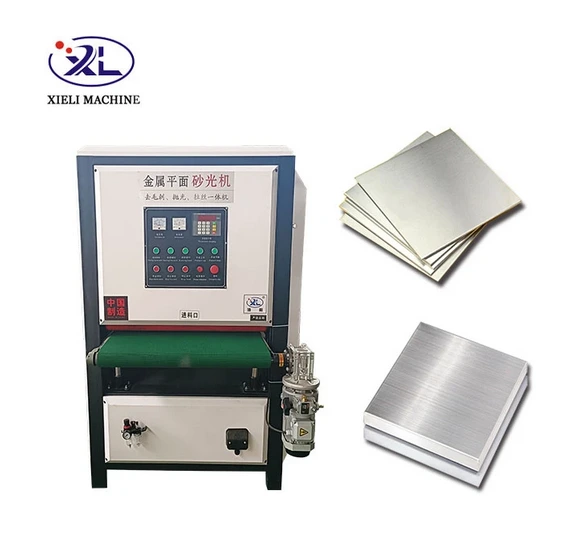

Modern fabrication facilities demand high throughput without compromising quality, and that is precisely where a stainless steel plate polishing machine becomes essential. It significantly boosts processing efficiency, enabling companies to meet bulk orders while maintaining impeccable finish standards. These machines are engineered to handle varying plate thicknesses and sizes, adapting to the specific needs of industries such as automotive, shipbuilding, architecture, and kitchenware manufacturing. The ability to uniformly polish large stainless steel plates ensures consistency and visual appeal, crucial for industries that emphasize aesthetics as well as function.

Enhancing Surface Integrity with Precision-Driven Metal Sheet Grinding Machine Solutions

To achieve reliable structural performance, metal components must be free of imperfections and surface contaminants. That’s why many industries are now relying on a metal sheet grinding machine to prepare surfaces before welding, coating, or further processing. Positioned midway in the production line, these machines remove burrs, rust, and oxide layers while leveling micro-deformations. By doing so, they improve surface adhesion for paints and coatings and ensure dimensional stability. The integration of programmable logic controllers and smart sensors further enhances operational control, safety, and repeatability across large-scale industrial applications.

Operational Efficiency Gains with Sheet Metal Grinding Machine Deployments

Manufacturers are increasingly adopting the sheet metal grinding machine not just for its functionality but also for its automation potential. Automated feeding systems, adjustable grinding speeds, and precision abrasives allow for continuous operation with minimal human intervention. These machines are vital in sectors like aerospace, where every surface imperfection could translate into performance failures. In such industries, grinding machines act as gatekeepers, ensuring only flawless sheet metal components advance through the production process. Their integration also reduces worker fatigue and occupational hazards associated with manual grinding, promoting workplace safety.

Precision Buffing Through Advanced Automatic Buffing Machine Stainless Steel Systems

The final touch in any metal finishing operation is often the most critical. A high-performance automatic buffing machine stainless steel system can deliver a mirror-like finish that not only enhances the appearance but also adds a layer of corrosion resistance. These machines utilize rotating wheels and abrasive compounds to finely polish stainless steel components with unparalleled consistency. They’re a staple in industries where presentation matters, such as elevator manufacturing, luxury appliances, and high-end metal décor. With automatic feed and pressure regulation, these buffing machines ensure uniform finish even on complex geometries, all while optimizing material usage and operational time.

Why Stainless Steel Sheet Polishing Matters in Industrial Applications

Polished stainless steel isn't just about aesthetics—it improves corrosion resistance, hygiene, and wear tolerance. This is especially valuable in sectors like pharmaceuticals and food processing, where hygiene is paramount and polished surfaces are easier to clean and maintain.

Key Factors When Choosing a Metal Sheet Grinding Machine

Selecting the right grinding machine involves evaluating material thickness, throughput requirements, abrasive types, and automation level. Customizable setups ensure that the machine aligns with your production flow, budget, and surface quality needs.

Automation Trends in Stainless Steel Buffing and Polishing

Modern polishing machines now feature AI-driven control systems, real-time performance analytics, and automatic defect detection. These technologies reduce waste, lower labor costs, and ensure a more consistent product output across large batches.

Industrial Polishing Equipment FAQs

Q: What industries benefit most from stainless steel sheet polishing machine manufacturers?

A: Industries such as construction, automotive, aerospace, food processing, and pharmaceuticals benefit immensely due to their demand for hygienic, corrosion-resistant, and visually appealing components.

Q: How does a stainless steel plate polishing machine differ from a general sheet polisher?

A: A stainless steel plate polishing machine is designed to handle heavier, thicker, and larger plates with greater force and durability, often tailored for high-volume industrial use.

Q: Can a metal sheet grinding machine work on both stainless steel and aluminum?

A: Yes, with the correct abrasives and speed settings, many grinding machines are versatile enough to handle different metal types including stainless steel and aluminum.

Q: What is the maintenance requirement for a sheet metal grinding machine?

A: Regular maintenance includes abrasive replacement, lubrication of moving parts, dust extraction system cleaning, and software updates to ensure optimal performance.

Q: Are automatic buffing machines suitable for complex shapes?

A: Absolutely. Advanced automatic buffing machines can be configured with adjustable arms and adaptive controls to polish intricate surfaces with high precision.

By leveraging these technologies, industries can not only enhance product quality but also increase operational efficiency, reduce costs, and maintain a competitive edge in the global marketplace.