Exploring the World of Retrofit Servo Centerless Grinders A Focus on Exporters

In today’s fast-paced industrial environment, maintaining precision and efficiency in the manufacturing process is paramount. One crucial aspect of this is the grinding process, and among the various types of grinders available, centerless grinders hold a significant position. However, with advancements in technology, traditional centerless grinders can be retrofitted with servo systems to enhance their performance. This article delves into the concept of retrofit servo centerless grinders and the role of exporters in bringing this technology to global markets.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. The unique design of centerless grinders allows them to grind cylindrical parts without the need for the workpiece to be clamped between centers. This results in higher efficiency and easier production flow, making centerless grinding a preferred choice for various industries, including automotive, aerospace, and medical manufacturing.

The Retrofit Servo Advantage

The introduction of servo motors into centerless grinding machines marks a significant advancement in grinding technology. Retrofit servo centerless grinders utilize servo motors to achieve greater precision and control over the grinding process. Unlike traditional grinders that rely on mechanical components, servo-driven systems offer

1. Enhanced Accuracy Servo motors provide precise control over the grinding wheel and workpiece speeds, resulting in improved dimensional tolerances.

3. Flexibility Retrofit servo systems can be tailored to specific applications, making it easier for manufacturers to adapt to changing production demands.

retrofit servo centerless grinder exporter

4. Reduced Maintenance By integrating modern servo technology, these grinders tend to have lower wear rates and require less frequent maintenance, ultimately reducing operational costs.

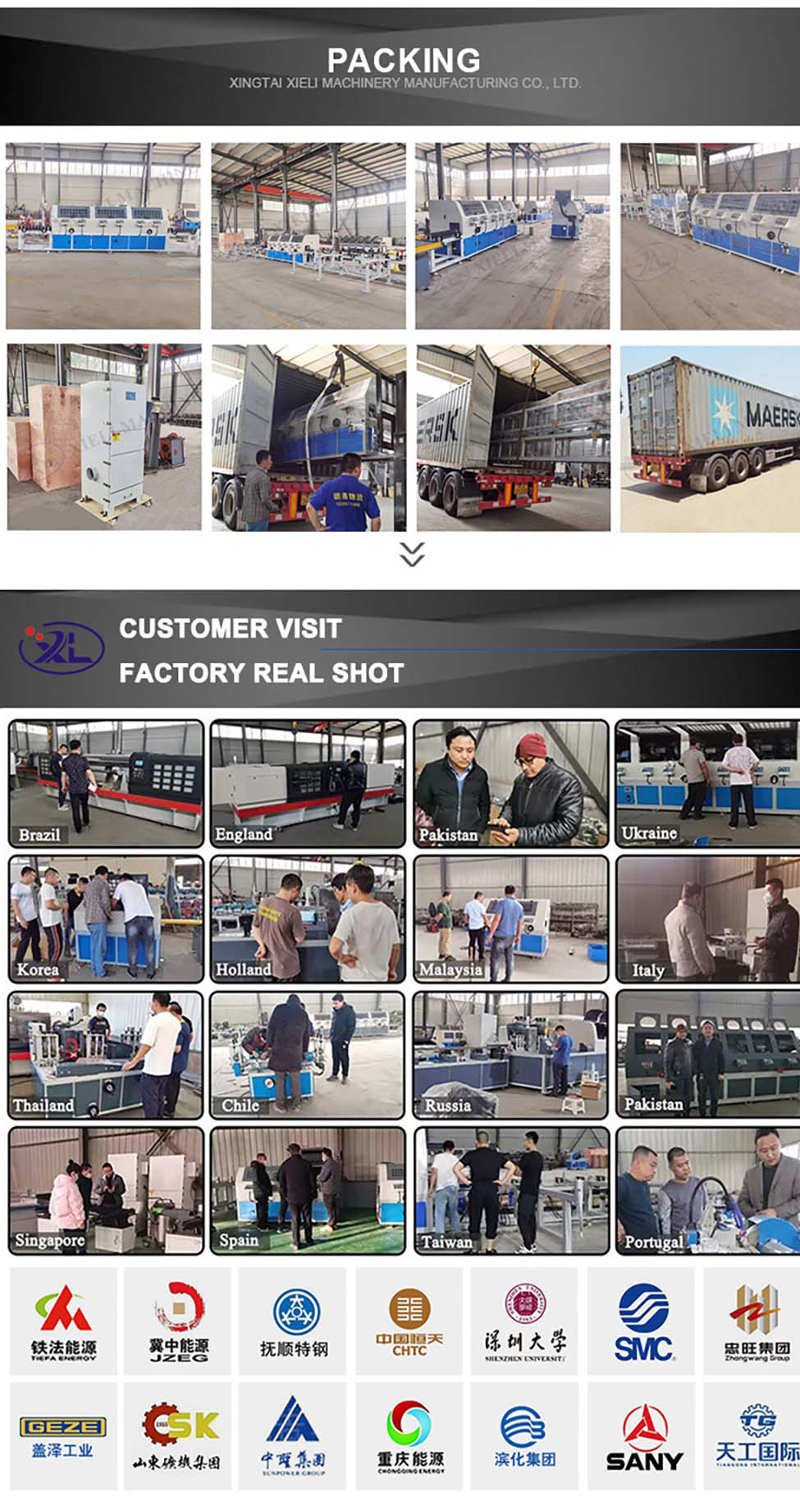

The Role of Exporters in the Global Market

As industries worldwide continue to seek efficient and precise grinding solutions, the demand for retrofit servo centerless grinders has surged. Exporters play a crucial role in facilitating this demand by connecting manufacturers with innovative grinding technologies. Here's how they contribute to the ecosystem

1. Market Expansion Exporters help manufacturers access global markets, allowing them to compete on a larger scale. By providing advanced grinding solutions, they enable companies to enhance their production capabilities.

2. Technical Support and Training Many exporters not only supply retrofitted machines but also offer technical support, installation, and training. This ensures that manufacturers can effectively implement and operate their new grinding systems.

3. Customization Different industries have varying requirements for grinding processes. Exporters often work closely with manufacturers to customize retrofit solutions that meet specific needs, further enhancing operational efficiency.

4. Quality Assurance Reputable exporters maintain strict quality control standards, ensuring that the machines they provide meet the necessary industry certifications and performance benchmarks. This builds trust and reliability in the technology they export.

Conclusion

The integration of servo systems into centerless grinders represents a significant leap forward in manufacturing technology. Retrofit servo centerless grinders not only improve the precision and efficiency of the grinding process but also offer manufacturers the flexibility to adapt to varying production demands. Exporters serve as vital links in this technological advancement, providing access to the latest grinding solutions and supporting manufacturers in optimizing their operational capabilities. As industries continue to evolve, the role of retrofit servo centerless grinder exporters will undoubtedly become even more critical in shaping the future of manufacturing. With their ability to enhance productivity, reduce costs, and improve quality, these systems are set to redefine the standards of grinding technology globally.