Troubleshooting Guide for Inexpensive Centerless Grinders

When dealing with an affordable centerless grinder, it's essential to understand that while it provides cost-effective solutions, it may also encounter some operational issues. This troubleshooting guide aims to assist you in identifying and resolving common problems you might face with your cheap centerless grinder.

1. **Uneven Grinding** If you notice inconsistent or uneven grinding, the issue could be with the work rest blade or the regulating wheel. Check if they are correctly adjusted and aligned. Uneven wear on these components can lead to irregularities. Adjust them as needed, ensuring a consistent gap between the grinding wheel and the workpiece.

2. **Vibrations** Excessive vibrations can affect the precision of your grinding process. They may be caused by imbalance in the grinding wheel, worn bearings, or loose mounting. Balance the wheel properly, inspect and tighten any loose parts, and replace worn-out bearings to minimize vibrations.

3. **Slippage** If the workpiece is slipping during the grinding process, it could indicate a problem with the friction provided by the regulating wheel. Ensure the regulating wheel is dressed properly and has the right pressure applied. Also, check for any contamination that could reduce friction.

4. **Overheating** Overheating can damage the workpiece and shorten the life of your grinder **Overheating** Overheating can damage the workpiece and shorten the life of your grinder

**Overheating** Overheating can damage the workpiece and shorten the life of your grinder **Overheating** Overheating can damage the workpiece and shorten the life of your grinder

cheap centerless grinder troubleshooting

cheap centerless grinder troubleshooting. It could be due to excessive grinding pressure, a clogged coolant system, or a worn-out grinding wheel. Reduce the pressure, clean the coolant system, and replace the worn wheel as necessary.

5. **Inaccurate Workpiece Diameter** If the ground workpieces are not achieving the desired diameter, check the setup of your centerless grinder. The angle of the regulating wheel and the position of the work rest blade can significantly impact the accuracy. Make sure these are set according to the manufacturer's specifications.

6. **Power Issues** If the grinder fails to start or operates weakly, check the power supply and wiring. Make sure the voltage matches the machine's requirement and there are no damaged cords or loose connections.

Remember, prevention is always better than cure. Regular maintenance, such as cleaning, lubrication, and timely component replacement, can help avoid many of these issues. Always refer to the manufacturer's manual for specific instructions and safety precautions. If the problem persists, don't hesitate to seek professional assistance to avoid causing more damage or voiding the warranty.

In conclusion, while a cheap centerless grinder might come with its set of challenges, understanding these troubleshooting steps will enable you to maximize its efficiency and lifespan. With patience and proper care, even an inexpensive grinder can deliver reliable performance.

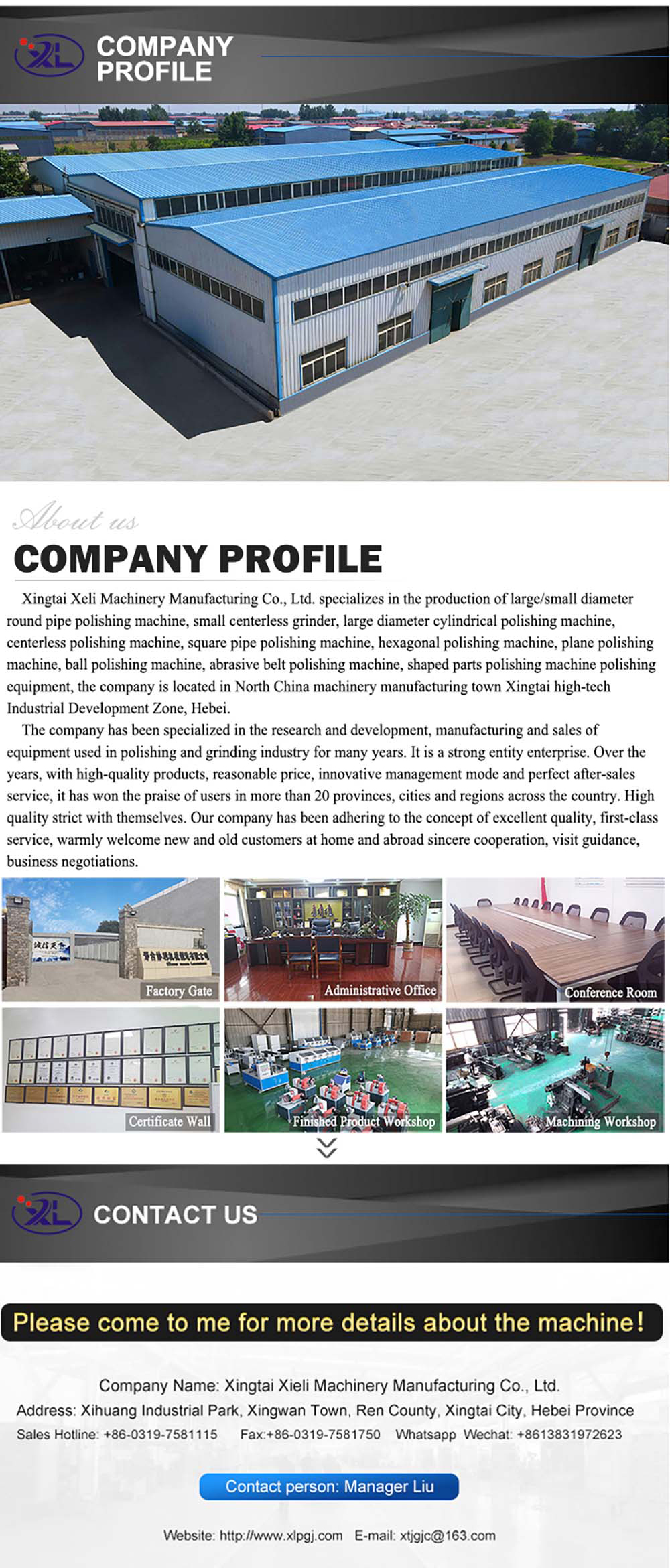

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.

**Overheating** Overheating can damage the workpiece and shorten the life of your grinder **Overheating** Overheating can damage the workpiece and shorten the life of your grinder

**Overheating** Overheating can damage the workpiece and shorten the life of your grinder **Overheating** Overheating can damage the workpiece and shorten the life of your grinder cheap centerless grinder troubleshooting. It could be due to excessive grinding pressure, a clogged coolant system, or a worn-out grinding wheel. Reduce the pressure, clean the coolant system, and replace the worn wheel as necessary.

5. **Inaccurate Workpiece Diameter** If the ground workpieces are not achieving the desired diameter, check the setup of your centerless grinder. The angle of the regulating wheel and the position of the work rest blade can significantly impact the accuracy. Make sure these are set according to the manufacturer's specifications.

6. **Power Issues** If the grinder fails to start or operates weakly, check the power supply and wiring. Make sure the voltage matches the machine's requirement and there are no damaged cords or loose connections.

Remember, prevention is always better than cure. Regular maintenance, such as cleaning, lubrication, and timely component replacement, can help avoid many of these issues. Always refer to the manufacturer's manual for specific instructions and safety precautions. If the problem persists, don't hesitate to seek professional assistance to avoid causing more damage or voiding the warranty.

In conclusion, while a cheap centerless grinder might come with its set of challenges, understanding these troubleshooting steps will enable you to maximize its efficiency and lifespan. With patience and proper care, even an inexpensive grinder can deliver reliable performance.

cheap centerless grinder troubleshooting. It could be due to excessive grinding pressure, a clogged coolant system, or a worn-out grinding wheel. Reduce the pressure, clean the coolant system, and replace the worn wheel as necessary.

5. **Inaccurate Workpiece Diameter** If the ground workpieces are not achieving the desired diameter, check the setup of your centerless grinder. The angle of the regulating wheel and the position of the work rest blade can significantly impact the accuracy. Make sure these are set according to the manufacturer's specifications.

6. **Power Issues** If the grinder fails to start or operates weakly, check the power supply and wiring. Make sure the voltage matches the machine's requirement and there are no damaged cords or loose connections.

Remember, prevention is always better than cure. Regular maintenance, such as cleaning, lubrication, and timely component replacement, can help avoid many of these issues. Always refer to the manufacturer's manual for specific instructions and safety precautions. If the problem persists, don't hesitate to seek professional assistance to avoid causing more damage or voiding the warranty.

In conclusion, while a cheap centerless grinder might come with its set of challenges, understanding these troubleshooting steps will enable you to maximize its efficiency and lifespan. With patience and proper care, even an inexpensive grinder can deliver reliable performance.