Square tube grinding machines are indispensable tools in the metal fabrication industry, offering precision and efficiency in finishing square and rectangular tubes. The meticulous design of these machines ensures a smooth and consistent surface finish, which is crucial for a variety of applications, from construction to automotive industries.

When selecting a square tube grinding machine, it's essential to consider several factors that contribute to the machine's quality and performance. One of the key considerations is the built quality and durability. High-grade materials contribute to the longevity and reliability of the machine, ensuring it withstands the rigors of intense and prolonged operations. Machines constructed with robust steels and alloys provide the necessary resilience against wear and tear.

Moreover, the precision of the grinding process is enhanced by advanced control systems integrated into modern grinding machines. These systems offer unparalleled accuracy, allowing for precise adjustments and consistency in output. The ability to program specific settings caters to the distinct requirements of different projects, making these machines highly versatile. Operators often remark on the user-friendly interfaces that simplify the setup and monitoring processes, which also reduces the learning curve associated with operating such complex machinery.

The expertise embedded in the design of square tube grinding machines is evident in their adaptability to various tube sizes and materials. Whether dealing with stainless steel, aluminum, or more exotic metals, the machine accommodates the unique properties of each material, adjusting grinding pressure and speed accordingly. This adaptability not only improves efficiency but also enhances product quality, minimizing material wastage and imperfections.

Safety is another critical aspect that cannot be overlooked. The integration of safety features such as emergency stop buttons, protective guards, and automatic shut-off mechanisms protects operators from hazards associated with the grinding process. Comprehensive training and clear operational guidelines further ensure a safe working environment, building trust in the technology employed.

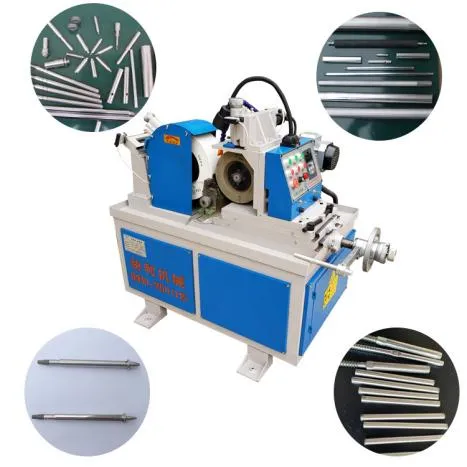

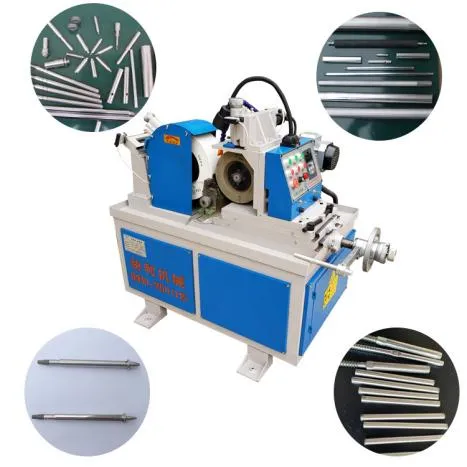

square tube grinding machine

From the perspective of energy efficiency, modern square tube grinding machines are equipped with energy-saving motors and drives that reduce operational costs while maintaining performance standards. Environmentally conscious businesses can benefit from selecting machines with low power consumption, aligning with sustainable practices without compromising on efficiency.

A notable advantage of state-of-the-art square tube grinding machines is the reduction in maintenance requirements. With fewer moving parts and robust construction, these machines require minimal servicing, translating to lower maintenance costs and reduced downtime. Enhanced diagnostics allow for predictive maintenance, identifying issues before they escalate, thereby ensuring uninterrupted production processes.

Industry professionals often commend the authority of leading manufacturers in the square tube grinding domain, who bring years of innovation and refinement to their products. These manufacturers not only offer comprehensive warranties and customer support but also contribute to the body of knowledge through detailed research and development efforts.

Such commitment to quality and service bolsters trust in their machines' capabilities.

In conclusion, square tube grinding machines are vital components in modern fabrication setups, defined by their precision, efficiency, and adaptability. With advancements in technology and design, these machines not only meet but exceed industry standards, offering a reliable solution for businesses seeking quality and consistency in their tube finishing processes. By prioritizing durability, safety, and performance, companies can achieve outstanding results, reflecting expertise and trustworthiness in their production capabilities.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.