Selecting the right round pipe polishing machine is critical for businesses looking to enhance their product finishing standards and streamline their operation processes. As an industry expert with years of hands-on experience, I've seen firsthand the transformative impact these machines can have on production efficiency and product quality. This article will explore various facets of round pipe polishing machines, emphasizing practical expertise, authoritative insights, and trustworthiness to help you make informed decisions.

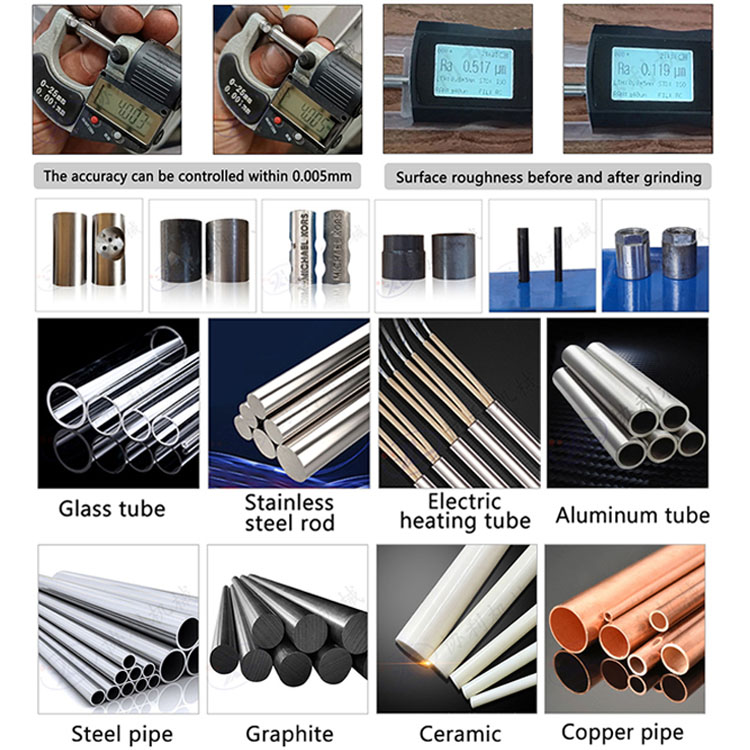

Round pipe polishing machines are pivotal in various industries, including automotive, construction, and manufacturing, where precision and superb surface finishing are prerequisites. The evolution of these machines has been remarkable, evolving from rudimentary designs to sophisticated, automated systems capable of achieving consistent and high-quality finishes.

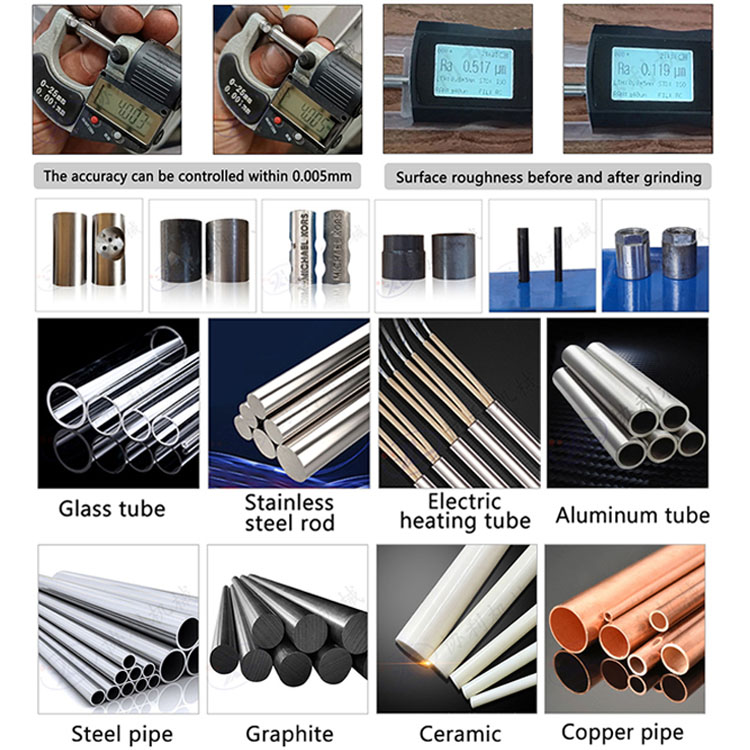

Firstly, understanding the core aspects of round pipe polishing machines is vital. They are designed to polish the surface of cylindrical workpieces, typically metal pipes, to remove surface imperfections, enhance surface finish, and prepare the pipes for subsequent processes such as painting or coating. The efficiency of these machines depends on factors such as the speed adjustment capability, abrasive type compatibility, and the machine's ability to maintain a consistent finish across various pipe diameters.

From a technical standpoint,

the expertise lies in the machine's adaptability and precision. Modern round pipe polishing machines are equipped with advanced features like adjustable contact rollers, variable speed drives, and computerized control systems, enabling operators to tailor the polishing process to specific material requirements and desired finish levels. Understanding how these features work and how they can be optimized for different materials and finishing requirements is essential for maximizing the machine's potential.

round pipe polishing machine

Authoritativeness in choosing a round pipe polishing machine comes from recognizing the manufacturers who integrate the latest technology and adhere to the highest industry standards. Reliable manufacturers offer not only robustly built machines but also provide comprehensive warranties and responsive customer service. They often have a track record of continuous innovation in their product lines, incorporating advancements in automation, energy efficiency, and dust control, which are crucial for sustainable operations.

The element of trustworthiness, particularly with heavy-duty machinery investments, cannot be overstated. Partnering with manufacturers who provide thorough training sessions and detailed operational manuals ensures that operators can use these machines safely and effectively. Additionally, seeking out user testimonials and reviews can provide valuable insights into the machine's long-term performance and the manufacturer's commitment to customer satisfaction.

To conclude, while round pipe polishing machines are an asset to any manufacturing setup focused on high-quality outputs, the success of integrating such a machine into your production line hinges on informed and strategic choices. Delving into the intricacies of machine operations, investing in reputable brands, and prioritizing safety and training can significantly influence the overall productivity and success of your operations. For businesses aiming to stay competitive, aligning with the right round pipe polishing technology is not just advantageous—it's essential.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.