Precision Centerless Grinder Service Ensuring Optimal Performance

In the world of manufacturing and precision machining, the ability to produce parts with exacting specifications is crucial. A key player in this field is the centerless grinder, a machine that has become indispensable for achieving high levels of precision in the production of cylindrical parts. However, just like any other sophisticated equipment, centerless grinders require regular maintenance and service to maintain their performance. This article delves into the importance of precision centerless grinder service and how it can significantly enhance productivity and prolong machine life.

Understanding Centerless Grinding

Centerless grinding is a machining process that enables the production of cylindrical parts without the need for a spindle. The part is held between two grinding wheels a regulating wheel and a grinding wheel. The regulating wheel controls the rotational speed and the position of the workpiece, while the grinding wheel is responsible for removing material from the workpiece to achieve the desired dimensions and surface finish.

One of the main advantages of centerless grinding is its ability to handle multiple parts simultaneously, which significantly increases production efficiency. This is particularly beneficial for high-volume manufacturing industries, such as automotive and aerospace, where precision and speed are paramount.

The Importance of Precision Service

To ensure that a centerless grinder operates at its best, regular service and maintenance are essential. Over time, wear and tear can affect the grinding wheels, machine alignment, and various components. Neglecting maintenance can lead to decreased performance, increased downtime, and ultimately, costly repairs.

Here are some key reasons why precision centerless grinder service should not be overlooked

1. Improved Accuracy and Consistency Regular maintenance helps in keeping the machine precisely aligned, ensuring that every part produced is consistent in quality. This is vital in industries where tolerances are tight and even minor deviations can lead to significant issues.

2. Extended Equipment Life Just like any machine, the centerless grinder has components that experience wear. Routine service can identify potential problems before they cause breakdowns, extending the life of the machine and protecting your investment.

3. Enhanced Safety A well-maintained centerless grinder is a safer machine. Regular checks can identify issues such as excessive vibrations, loose parts, or misalignment, all of which can pose safety risks to operators.

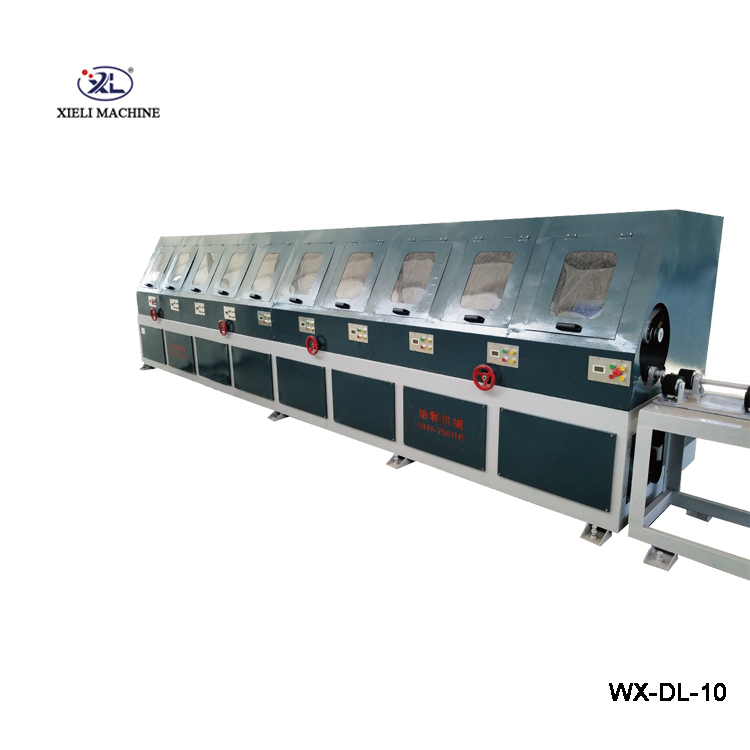

precision centerless grinder service

4. Increased Productivity Downtime due to machine failure can severely impact production schedules. By investing in regular service, manufacturers can minimize unexpected failures, ensuring smoother operations and higher productivity.

Key Aspects of Precision Service

Precision centerless grinder service encompasses several critical tasks, including

- Wheel Dressing and Replacement Grinding wheels need to be dressed regularly to maintain their cutting ability. Over time, wheels can become glazed or worn, which affects grinding performance.

- Alignment Checks Ensuring that the machine’s components are correctly aligned is crucial for achieving the desired precision. Misaligned parts can lead to uneven wear and sub-par output.

- Lubrication Proper lubrication of moving parts reduces friction and wear, promoting smooth operation.

- Electrical Component Inspection Many centerless grinders have complex electrical systems. Regular checks can prevent electrical failures and ensure consistent machine performance.

- Calibration Regular calibration of the machine settings is necessary to maintain accuracy in part production.

Conclusion

In today’s competitive manufacturing landscape, precision is key. A well-maintained centerless grinder not only enhances the quality of produced parts but also contributes to overall operational efficiency. By investing in precision centerless grinder service, manufacturers can ensure that their machines are running at peak performance, ultimately leading to improved profitability and customer satisfaction. Regular maintenance is not just a recommendation; it's a vital aspect of successful manufacturing operations.