From professional tournaments to home game rooms, ball polishing machine technology has revolutionized how cue sports equipment maintains its competitive edge. This comprehensive guide examines pool ball polisher machine systems, explores billiard ball polisher machine applications, and analyzes snooker ball polishing machine solutions - revealing how specialized polishing technology preserves the perfect roll and shine of game balls.

Ball Polishing Machine Fundamentals

Modern ball polishing machine units combine advanced abrasion technology with precision engineering to restore game balls to tournament standards. These systems utilize specialized polishing compounds and microfiber buffing wheels that gently remove surface imperfections without altering the ball's critical weight distribution. Contemporary ball polishing machine designs feature variable speed controls allowing operators to adjust for different ball materials - from traditional phenolic resins to modern polyester composites. The latest models incorporate self-cleaning mechanisms that maintain optimal polishing performance through extended use.

Pool Ball Polisher Machine Technology

The pool ball polisher machine represents a significant advancement over traditional hand-polishing methods. These automated systems typically process multiple balls simultaneously in a controlled environment that ensures uniform results. A standard pool ball polisher machine configuration includes micro-adjustable pressure arms that accommodate varying ball diameters while maintaining consistent contact pressure. Advanced pool ball polisher machine units now feature digital interfaces that store customized polishing programs for different ball sets and wear conditions.

Billiard Ball Polisher Machine Applications

Professional-grade billiard ball polisher machine systems serve commercial pool halls and serious enthusiasts who demand competition-ready equipment. These heavy-duty machines feature industrial-strength motors capable of processing hundreds of balls daily while maintaining precise polishing quality. Modern billiard ball polisher machine designs incorporate noise reduction technology and enclosed workspaces to minimize disturbance in gaming environments. The most advanced models include optical sensors that detect surface imperfections and automatically adjust polishing parameters for optimal results.

Snooker Ball Polishing Machine Specializations

Dedicated snooker ball polishing machine equipment addresses the unique requirements of snooker's slightly larger ball dimensions. These specialized polishers maintain perfect spherical geometry while restoring the high-gloss finish critical for accurate play. Premium snooker ball polishing machine models feature oversized polishing chambers that accommodate the game's 2-1/16" balls without compromising rotation dynamics. Many tournament-approved snooker ball polishing machine units include temperature-controlled polishing compounds that optimize performance under varying climate conditions.

Ball Polishing Machine Maintenance FAQ

What surface finishes can ball polishing machine achieve?

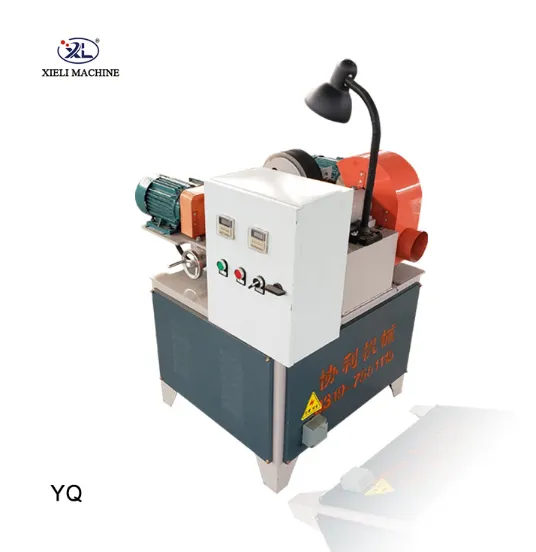

Round ball polisher is a patent product independently developed by our factory. Machine is equipped with a variety of grinding wheels (polishing wheels) to choose from. So as to achieve different grinding (polishing) effects, to meet the requirements of different customers on the workpiece. And it can be polished with variable speed to suit different diameter workpieces (optional). Round ball polisher is widely used in decoration, decoration, hardware plating, instrument accessories and other industries round ball polishing.

How Does Pool Ball Polisher Machine Technology Differ From Hand Polishing?

The pool ball polisher machine represents a quantum leap in consistency and precision compared to traditional hand polishing methods. While manual polishing relies on variable human pressure and motion patterns, the pool ball polisher machine employs precisely calibrated rotation mechanisms that apply uniform pressure across the entire ball surface. This automated process eliminates the inconsistencies inherent in hand polishing, where uneven pressure can create microscopic high and low spots that affect ball roll accuracy.

What Safety Features Do Billiard Ball Polisher Machine Include?

Modern billiard ball polisher machine designs prioritize user protection through multiple integrated safety systems. The enclosed polishing chamber serves as the primary safety barrier, preventing accidental contact with moving components during operation. Advanced billiard ball polisher machine models feature intelligent sensor systems that immediately halt operation if the chamber door is opened mid-cycle. These machines also incorporate thermal monitoring that automatically shuts down the unit if motor temperatures exceed safe thresholds. The low-voltage electrical systems in contemporary billiard ball polisher machine equipment significantly reduce shock hazards compared to earlier high-power models. Additional safety considerations include non-slip rubberized feet that stabilize the machine during use and emergency stop buttons positioned for immediate access.

Why Choose Dedicated Snooker Ball Polishing Machine Over Universal Models?

The snooker ball polishing machine offers specialized performance characteristics specifically engineered for the game's unique requirements. Unlike universal polishers that compromise on ball diameter specifications, the snooker ball polishing machine features precisely sized polishing chambers that maintain proper contact with the larger snooker balls. These dedicated machines use custom-formulated polishing compounds that enhance rather than alter the distinctive appearance of snooker balls.

What Maintenance Does Ball Polishing Machine Require?

Proper ball polishing machine maintenance ensures consistent performance and extends equipment lifespan. Regular compound replenishment maintains optimal polishing effectiveness, as depleted compounds lose their abrasive qualities and can actually damage ball surfaces. The ball polishing machine requires periodic microfiber pad replacement to prevent cross-contamination between different ball sets and maintain proper surface contact. Bearing lubrication should follow manufacturer recommendations to prevent premature wear in the rotation mechanisms.

From basic ball polishing machine units to tournament-grade snooker ball polishing machine systems, this specialized equipment continues evolving to meet the exacting standards of cue sports. The precision of pool ball polisher machine technology demonstrates how automated polishing surpasses manual methods, while professional billiard ball polisher machine solutions maintain equipment at peak performance. Whether for commercial establishments or serious enthusiasts, understanding these polishing systems ensures game balls always deliver perfect rolls and true rebounds.