Portable Pipe Polishing Machines Revolutionizing Surface Finishing

In the world of manufacturing and metalworking, the finishing touches are often just as important as the raw shaping and cutting of materials. This is particularly true for pipes, where surface quality can impact everything from aesthetics to functionality. With the rise of portable pipe polishing machines, companies are finding that they can achieve high-quality finishes with minimal effort, enhancing productivity and efficiency on job sites.

Understanding Portable Pipe Polishing Machines

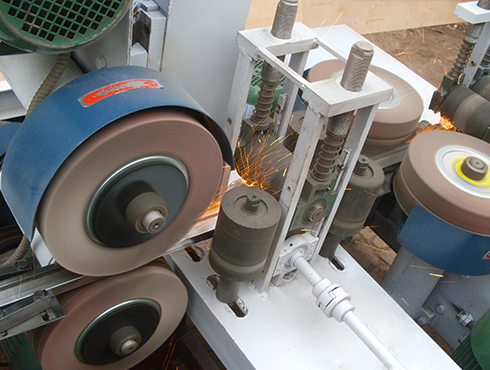

Portable pipe polishing machines are specially designed tools that facilitate the smoothing and shining of pipes and tubes. These machines are equipped with various attachments and abrasive materials that can mold to the contour of different pipe sizes and shapes, ensuring a thorough and uniform finish. Their portability allows for use in various settings, from factories to construction sites, making them incredibly versatile.

One of the significant advantages of portable pipe polishing machines is their user-friendly design. Many models incorporate ergonomic handles and lightweight materials, reducing operator fatigue during prolonged use. Additionally, advanced features like variable speed settings allow users to customize their polishing technique to suit specific requirements, be it for rough or fine finishes.

Customization for Different Industries

Different industries have different needs when it comes to pipe finishing. For example, the food and beverage industry requires pipes that comply with strict hygienic standards, necessitating a high level of polish to avoid contamination. On the other hand, the oil and gas sector may prioritize functionality over aesthetics but still requires pipes to be free of contaminants and surface imperfections that could lead to failure.

Modern portable pipe polishing machines cater to these diverse requirements by offering various polishing attachments and abrasive materials. This customization allows companies to use the same machine across different applications, making the investment cost-effective. Whether it’s stainless steel, carbon steel, or aluminum pipes, a well-designed polishing machine can handle it.

portable pipe polishing machine company

Improving Efficiency and Reducing Waste

The efficiency of portable pipe polishing machines can lead to considerable time and cost savings. Traditional polishing methods may involve laborious manual work, often resulting in inconsistent finishes and increased material waste. In contrast, automated and semi-automated systems can produce uniform results much more quickly and with precision. This consistency is particularly important in industries where quality assurance is paramount.

Moreover, improving the surface finish of pipes can enhance their lifespan and reduce operational costs. For instance, polished pipes are less likely to corrode, lowering maintenance needs and downtime. Businesses can, therefore, realize a more substantial return on investment through the use of these innovative machines.

Environmental Considerations

As industries become increasingly aware of their environmental impact, portable pipe polishing machines can offer more sustainable solutions. Many modern models incorporate dust and debris collection systems that minimize waste and reduce air pollution. Additionally, the efficiency of these machines can lead to less energy consumption over time, aligning with broader sustainability goals.

Conclusion

The advent of portable pipe polishing machines marks a significant advancement in the field of industrial polishing and finishing. These machines combine efficiency, versatility, and customization to meet the diverse needs of various sectors. As companies continue to seek ways to enhance productivity while adhering to quality standards, portable pipe polishing machines will undoubtedly play a crucial role in shaping the future of metalworking and manufacturing. As we move forward, embracing these cutting-edge tools can help businesses not only meet industry demands but also contribute to a more sustainable and efficient operational landscape.