Handheld Tube Polishing Machine Service Enhancing Your Metal Finishing Needs

In today's industrial landscape, the aesthetics and functionality of metal components are paramount. Whether for aesthetic appeal or anti-corrosion purposes, the polishing of metal tubes plays an essential role in manufacturing and maintenance across various industries. The handheld tube polishing machine service has emerged as a revolutionary solution, providing efficiency, precision, and versatility in metal finishing tasks.

Overview of Handheld Tube Polishing Machines

Handheld tube polishing machines are compact and portable devices designed specifically for polishing metal tubes. Unlike traditional polishing methods that may involve bulky machinery or manual labor, these machines allow operators to smooth and finish surfaces with ease. This innovation has made it possible for companies to achieve high-quality results without the need for extensive setups or large spaces.

Benefits of Handheld Polishing

1. Portability and Convenience One of the primary advantages of handheld tube polishing machines is their portability. Operators can easily maneuver these tools around various job sites, making them ideal for both in-house polishing and fieldwork. This convenience significantly reduces the time and labor needed to transport heavy, stationary polishing equipment.

2. Precision and Quality Handheld machines often come equipped with advanced features such as variable speed settings and interchangeable heads, allowing for fine-tuned control over the polishing process. The quality of the finish is often superior with these machines compared to manual polishing methods, which can be inconsistent and labor-intensive.

3. Versatility These machines can be used on various metal types, including stainless steel, aluminum, and brass, making them suitable for a multitude of applications. They are particularly beneficial in industries such as food processing, automotive, and aerospace, where polished tubes are critical for performance and safety.

4. Cost-Effective Solution While there may be an initial investment in quality handheld polishing machines, the long-term savings in labor costs and increased productivity can be significant. Companies can reduce downtime and enhance their production rates, ultimately leading to increased profitability.

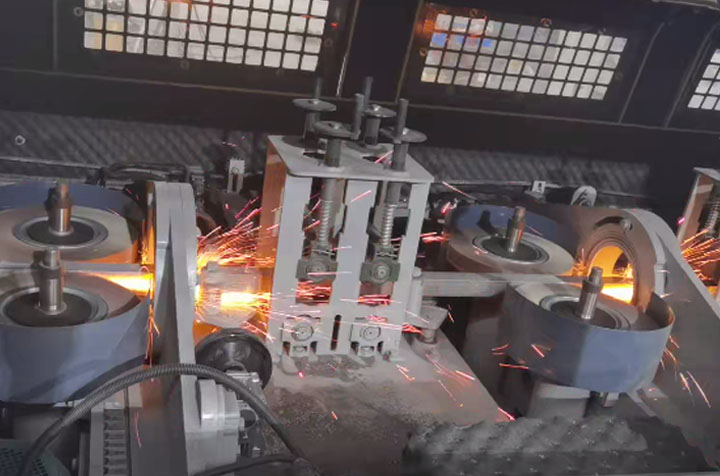

hand held tube polishing machine service

Maintenance and Service

To ensure optimal performance and longevity of handheld tube polishing machines, regular maintenance and professional servicing are essential. Here are some tips

- Routine Inspection Regularly check the machine for any signs of wear or damage. This includes examining cables, brush conditions, and polishing heads.

- Cleaning Keeping the machine clean of metal shavings and residue will help maintain its efficiency. After each use, operators should wipe down the machine and ensure the polishing heads are free of debris.

- Professional Servicing Scheduling periodic professional service can extend the life of your polishing machine significantly. Trained technicians can perform detailed inspections, replace worn parts, and ensure that the machine operates at peak performance.

Conclusion

The emergence of handheld tube polishing machine service has transformed the way industries approach metal finishing. With unparalleled portability, precision, and cost-effectiveness, these machines have become indispensable tools for anyone involved in metalworking. By investing in high-quality machines and ensuring regular maintenance, businesses can enhance their operational efficiency, improve the quality of their products, and stay competitive in today’s fast-paced market.

Whether you’re a small workshop or a large manufacturing facility, embracing handheld tube polishing technology can lead to significant improvements in both aesthetic and functional aspects of metal components. Engage with a professional service provider to explore the various options available and discover how these machines can elevate your production processes.