The Rise of Portable Pipe Polishing Machine Manufacturers

In recent years, the demand for high-quality, efficient pipe polishing solutions has surged in various industries, including construction, manufacturing, and automotive. The need for these solutions has given rise to a growing market for portable pipe polishing machines. As manufacturers strive to meet industry standards and customer expectations, innovating in design and functionality has become crucial.

Understanding Portable Pipe Polishing Machines

Portable pipe polishing machines are versatile tools designed to polish and finish pipes and tubes made from various materials, including stainless steel, aluminum, and carbon steel. These machines improve the aesthetic appeal of pipes by providing a smooth finish while also enhancing their resistance to corrosion and wear. The portability of these machines allows operators to work in tight spaces and transport them easily from one job site to another.

Advantages of Portable Pipe Polishing Machines

The primary advantage of portable pipe polishing machines is their convenience. Unlike traditional polishing machines that are often stationary and bulky, portable models are lightweight and compact, making them suitable for on-site use. This flexibility saves time and reduces overhead costs, as workers can perform polishing tasks without needing to transport pipes to a centralized facility.

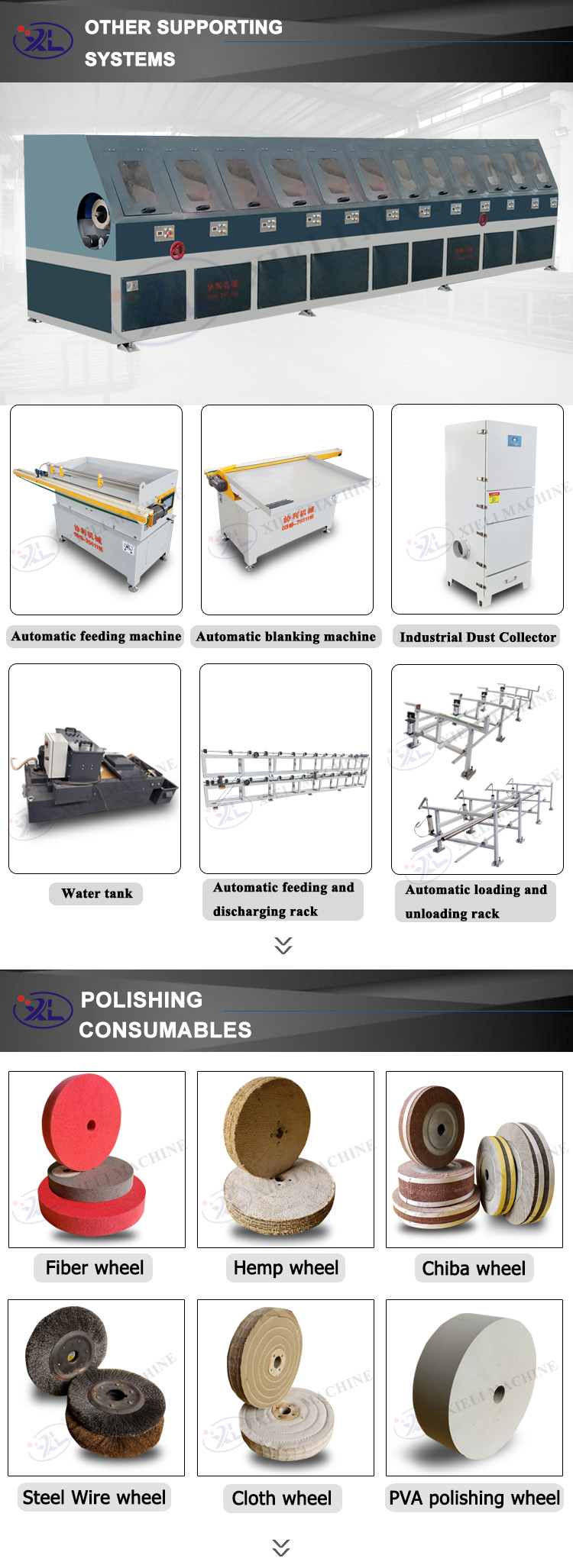

Additionally, these machines offer a wide range of polishing capabilities. With adjustable speed settings and various polishing attachments, users can achieve different finishes, from coarse to mirror-like, depending on the requirements of the project. This versatility is particularly beneficial in industries that work with intricate components or high-precision applications.

Innovation in Design and Technology

portable pipe polishing machine manufacturer

Manufacturers of portable pipe polishing machines are continuously innovating to improve performance and efficiency. Advances in technology have led to the development of machines that are not only more powerful but also more ergonomic. Features such as comfortable grips, adjustable handles, and noise-reduction technology enhance the user experience and promote safety.

Moreover, modern portable pipe polishing machines often incorporate digital controls that allow for precise adjustments and easier operation. This technological integration minimizes the risk of human error and ensures consistent polishing results, which is particularly important in industries where quality assurance is paramount.

The Future of Portable Pipe Polishing Machines

As industries continue to evolve, the future of portable pipe polishing machine manufacturers looks promising. With the push toward sustainable practices, we may see an increase in eco-friendly machines that consume less energy and utilize biodegradable polishing materials. Continued advancements in battery technology could also lead to the development of more powerful cordless models, further enhancing portability and convenience.

Additionally, the rising trend of automation and smart technology in manufacturing may soon be applied to pipe polishing machines. Features such as remote monitoring, data logging, and automated polishing cycles could revolutionize the way these machines are used, maximizing efficiency and minimizing downtime.

Conclusion

The demand for portable pipe polishing machines has opened new avenues for manufacturers to innovate and adapt to changing industry needs. As we look to the future, the combination of advanced technology, user-friendly designs, and a focus on sustainability will be key in shaping the development of these essential tools. Whether in a manufacturing facility or on a construction site, the role of portable pipe polishing machines will undoubtedly remain integral to achieving high-quality finishes on pipes and tubes. The ongoing evolution within this market promises exciting opportunities for manufacturers and users alike.