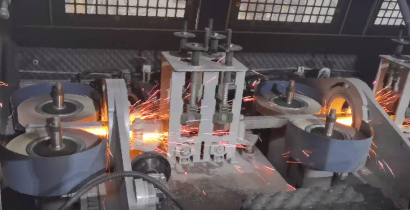

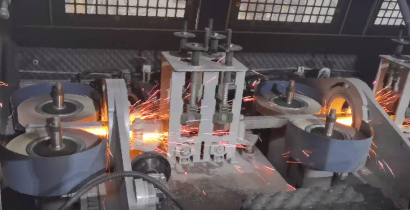

Unlike commercial models, a homemade centerless grinder allows for customization to suit specific needs Unlike commercial models, a homemade centerless grinder allows for customization to suit specific needs

Unlike commercial models, a homemade centerless grinder allows for customization to suit specific needs Unlike commercial models, a homemade centerless grinder allows for customization to suit specific needs famous diy centerless grinder. Whether it's a compact unit for small-scale projects or a larger setup for industrial applications, the possibilities are endless. One can experiment with different wheel sizes, adjustability features, and even incorporate advanced control systems for more refined operations.

Building a centerless grinder is not without its challenges. It demands patience, attention to detail, and a willingness to learn from trial and error. But the satisfaction derived from creating something so functional and precise is unparalleled. Moreover, the process fosters a deeper appreciation for the technology behind these machines, enhancing one's skills and knowledge in the field.

In conclusion, a DIY centerless grinder is more than just a tool; it's a testament to human ingenuity and the joy of craftsmanship. By taking on this project, enthusiasts not only gain a valuable asset for their workshop but also embark on a fulfilling learning experience that bridges the gap between theory and practice. So, whether you're a woodworking enthusiast, a metal fabrication hobbyist, or simply someone intrigued by the art of making, a famous DIY centerless grinder could be your next exciting adventure.

famous diy centerless grinder. Whether it's a compact unit for small-scale projects or a larger setup for industrial applications, the possibilities are endless. One can experiment with different wheel sizes, adjustability features, and even incorporate advanced control systems for more refined operations.

Building a centerless grinder is not without its challenges. It demands patience, attention to detail, and a willingness to learn from trial and error. But the satisfaction derived from creating something so functional and precise is unparalleled. Moreover, the process fosters a deeper appreciation for the technology behind these machines, enhancing one's skills and knowledge in the field.

In conclusion, a DIY centerless grinder is more than just a tool; it's a testament to human ingenuity and the joy of craftsmanship. By taking on this project, enthusiasts not only gain a valuable asset for their workshop but also embark on a fulfilling learning experience that bridges the gap between theory and practice. So, whether you're a woodworking enthusiast, a metal fabrication hobbyist, or simply someone intrigued by the art of making, a famous DIY centerless grinder could be your next exciting adventure.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.