The Planetary Pipe Polishing Machine Revolutionizing Pipe Finishing

In the modern manufacturing landscape, the need for high-quality finishes on metal components is more critical than ever. One of the innovations that has emerged to meet this demand is the planetary pipe polishing machine. This advanced equipment is designed to provide superior finishing for pipes and tubes, ensuring that they meet stringent quality standards while enhancing their aesthetic appeal.

Understanding the Planetary Pipe Polishing Machine

A planetary pipe polishing machine operates on a unique principle that allows it to polish pipes with a high degree of efficiency and consistency. Unlike traditional polishing methods, which can be time-consuming and labor-intensive, the planetary system employs a series of rotating heads that move in a planet-like orbit around the pipe. As these heads rotate, they apply abrasive materials to the surface of the pipe, effectively removing imperfections, irregularities, and oxidation while producing a smooth, shiny finish.

The key components of a planetary pipe polishing machine typically include polishing heads, abrasive belts or discs, a cooling system to prevent heat buildup, and an automated control system that regulates speed and pressure. This combination of features makes the machine suitable for a variety of pipe materials, including stainless steel, aluminum, and carbon steel.

Advantages of Using a Planetary Pipe Polishing Machine

1. Efficiency One of the standout features of the planetary pipe polishing machine is its efficiency. The design allows multiple polishing heads to work simultaneously, significantly reducing the time required to achieve the desired finish. This is particularly beneficial in high-volume manufacturing environments where time is of the essence.

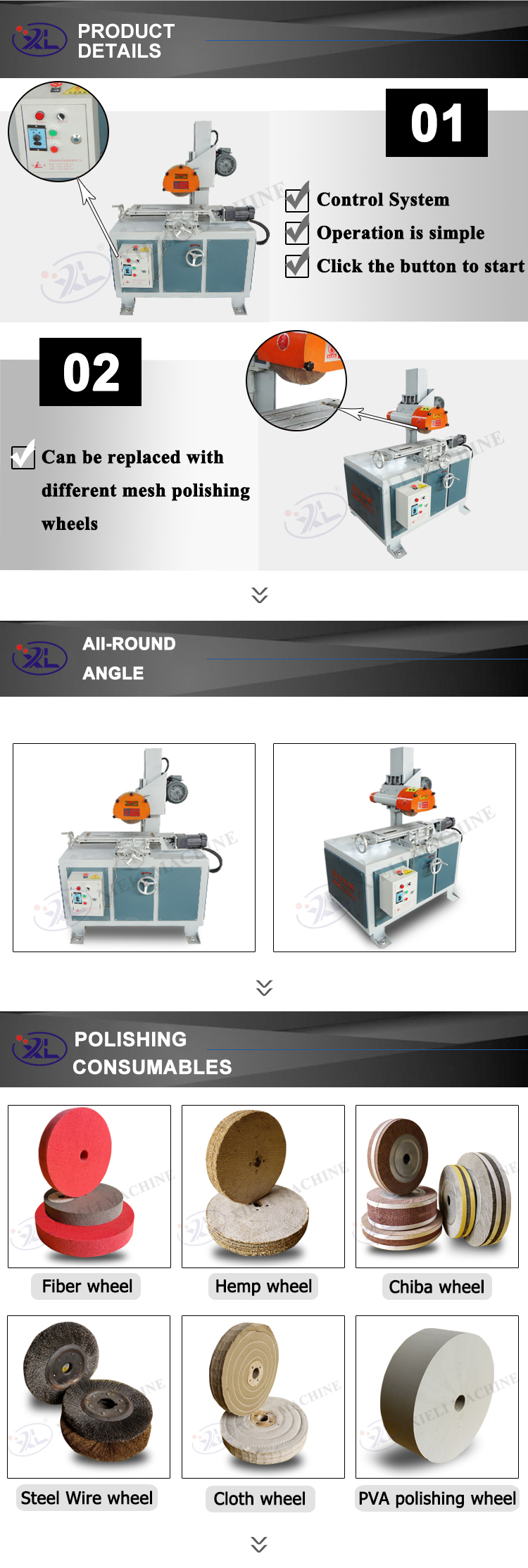

planetary pipe polishing machine product

2. Consistency Achieving a uniform finish is crucial, especially in industries such as aerospace, automotive, and food processing, where surface quality can impact performance and compliance with regulations. The automated and controlled nature of the polishing process ensures that every pipe is finished to the same high standard, minimizing the risk of inconsistencies that can arise from manual polishing methods.

3. Versatility The planetary pipe polishing machine is designed to accommodate a wide range of pipe sizes and shapes. Whether working with thin-walled tubes or thick-walled pipes, the machine can be adjusted to deliver optimal results for different applications. Additionally, various types of abrasive materials can be used, allowing manufacturers to tailor the polishing process to different finishes and surface requirements.

4. Cost-Effectiveness While the initial investment in a planetary pipe polishing machine may be higher than traditional polishing methods, the long-term cost savings are significant. Reduced labor costs, shorter processing times, and lower material waste contribute to an overall decrease in production costs, making this technology a wise investment for forward-thinking manufacturers.

5. Enhanced Aesthetic Appeal In many industries, the visual aspect of products can greatly influence purchasing decisions. The high-gloss finishes achieved through planetary polishing not only enhance the aesthetic appeal of pipes but also improve their corrosion resistance and longevity.

Conclusion

The planetary pipe polishing machine represents a significant advancement in the field of metal finishing technology. Its ability to deliver efficient, consistent, and high-quality results makes it an invaluable asset for manufacturers looking to enhance their product offerings. As industry standards continue to rise and the demand for aesthetically pleasing metal products increases, investing in advanced equipment like the planetary pipe polishing machine will undoubtedly provide manufacturers with a competitive edge in the market.

In a world where quality and efficiency are paramount, the planetary pipe polishing machine stands out as a solution that meets the rigorous demands of modern manufacturing while driving innovation and excellence in pipe finishing processes. As more industries recognize the benefits of this cutting-edge technology, we can expect to see broader adoption and continued advancements that will shape the future of metal fabrication and finishing.