Planetary Pipe Polishing Machine Revolutionizing Surface Finishing

In the modern manufacturing landscape, the quest for precision and quality has never been more critical. Industries that rely on metal components, such as aerospace, automotive, and construction, necessitate processes that not only meet high standards but also enhance the performance and longevity of their products. One such innovation making waves in surface finishing technology is the planetary pipe polishing machine.

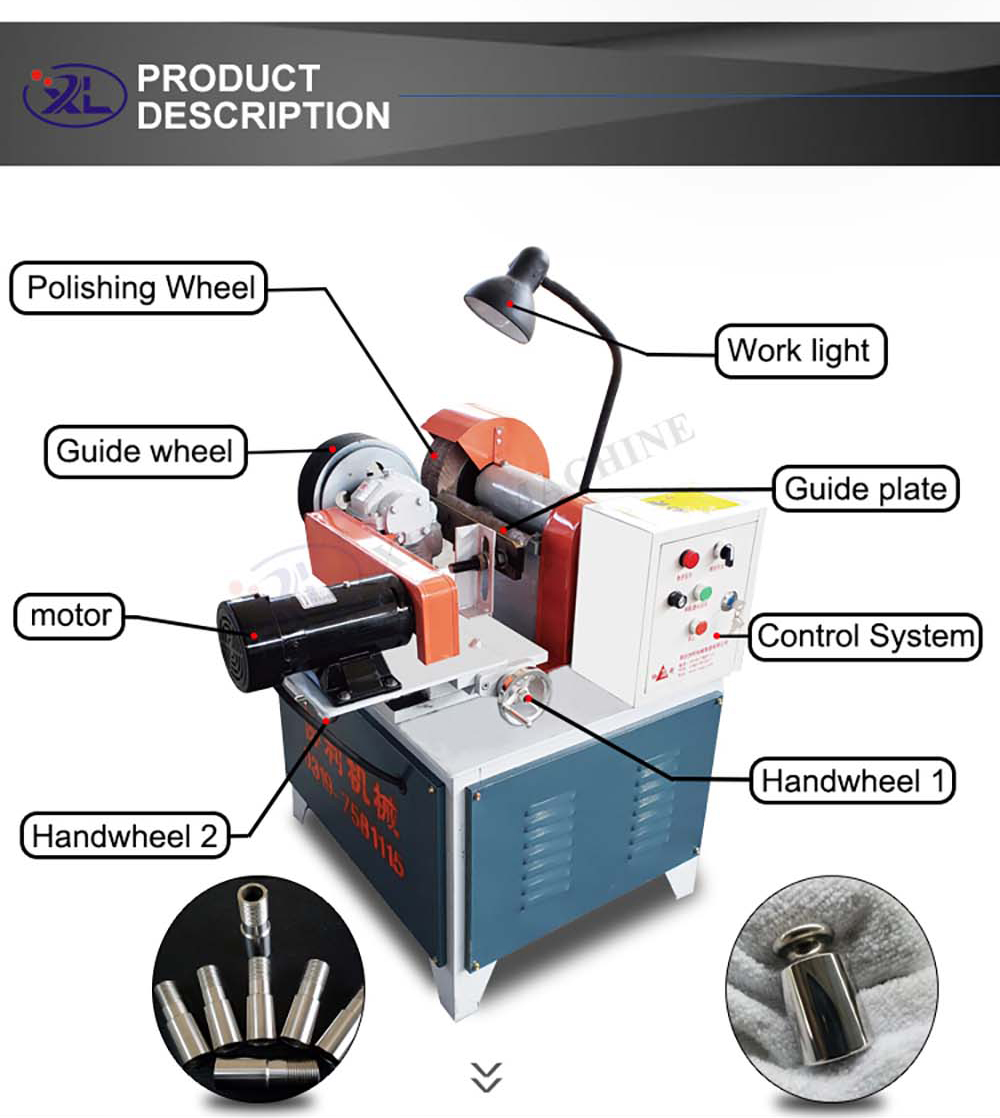

A planetary pipe polishing machine is designed to polish and finish pipe surfaces to achieve a mirror-like quality. It operates on an advanced mechanism where polishing tools move in a planetary motion around the pipe's surface. This movement ensures even coverage and consistent results, addressing common challenges faced with traditional polishing techniques. The adaptability of these machines allows them to handle various pipe sizes and materials, making them suitable for a diverse range of applications.

The main advantage of a planetary pipe polishing machine is its efficiency. Traditional metal polishing methods can be labor-intensive and time-consuming. With the planetary system, polishing is achieved much quicker without compromising quality. This efficiency translates into reduced operational costs and increased productivity for manufacturers. Moreover, the uniform finish achieved reduces the need for additional post-processing, further streamlining the finishing process.

planetary pipe polishing machine

Another significant benefit is the enhanced surface quality. A well-polished pipe exhibits improved corrosion resistance, reduced friction, and better aesthetic appeal. These characteristics are vital for industries where pipe integrity is non-negotiable. For example, in the pharmaceutical or food processing sectors, the risk of contamination is minimized when pipes have smooth and flawless surfaces.

Additionally, the planetary pipe polishing machine is equipped with advanced control systems that allow for precise adjustments. Operators can easily set parameters such as pressure, speed, and polishing duration based on the specific requirements of the material being processed. This level of control not only enhances the operational efficiency but also ensures that the finished product meets or exceeds industry standards.

As sustainability becomes an increasingly important consideration in manufacturing, the planetary pipe polishing machine also offers eco-friendly advantages. These machines typically use less energy and generate less waste compared to conventional polishing methods. Furthermore, improved finishes can lead to longer-lasting products, thereby reducing the frequency of replacements and the associated environmental impact.

In conclusion, the planetary pipe polishing machine is a game-changer in the realm of surface finishing. Its efficiency, quality of output, adaptability, and sustainability align perfectly with the requirements of modern industries. As manufacturers continue to embrace innovative technologies, the adoption of such advanced machines will pave the way for enhanced productivity and improved product standards in the years to come.