Exploring Pipe Rust Remover Machine Suppliers

In the industrial and manufacturing sectors, the maintenance of equipment is crucial to ensuring efficiency and longevity. One common issue that many operations face is rust accumulation on pipes, which can lead to significant operational challenges. To address this problem, many companies are turning to pipe rust remover machines. In this article, we will explore the importance of these machines, their benefits, and what to look for when considering suppliers.

The Importance of Rust Removal

Rust is a form of corrosion that commonly affects metal pipes, particularly those made of iron or steel. When rust forms, it can significantly weaken the structural integrity of the pipes and potentially lead to leaks or complete failures. This not only poses serious safety risks but can also result in costly repairs and downtime in production.

Regular maintenance and the removal of rust are essential practices for industries such as oil and gas, water treatment, and manufacturing. Without proper rust removal, the lifespan of the pipes can be drastically reduced, leading to unexpected replacements and increased operational costs.

Benefits of Pipe Rust Remover Machines

Investing in a pipe rust remover machine offers numerous advantages

1. Efficiency These machines are designed to quickly and effectively remove rust from pipes, significantly reducing the time and effort needed for manual cleaning methods.

2. Enhanced Durability By regularly using rust remover machines, companies can prolong the lifespan of their pipes, reducing the frequency of replacements and repairs.

3. Improved Safety Rust can contribute to hazardous working conditions. By removing rust, businesses can ensure safer environments for their employees, reducing the risk of accidents.

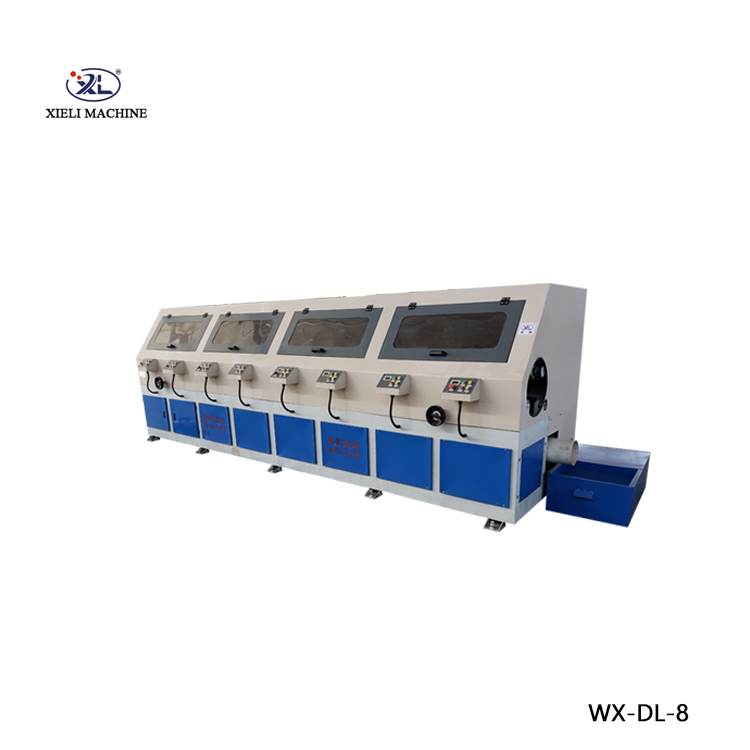

pipe rust remover machine supplier

5. Environmentally Friendly Options Many modern rust remover machines use eco-friendly methods and materials for rust removal, aligning with corporate sustainability goals.

Choosing the Right Supplier

With the growing demand for pipe rust remover machines, numerous suppliers have emerged in the market. However, finding the right supplier requires careful consideration. Here are some factors to keep in mind

1. Reputation and Experience Research the supplier’s background, including their years in business and customer reviews. A well-established supplier with a good reputation in the industry is often a safer choice.

2. Product Range Different operations may require different types of rust removal machines. Ensure the supplier offers various models and configurations that fit your specific needs.

3. Technology and Innovation The field of rust removal is continually evolving. A reliable supplier will stay up-to-date with the latest technology and offer machines that provide improved efficiency and effectiveness.

4. Customer Support Post-purchase support is crucial. The supplier should offer training, maintenance services, and technical support to ensure the machine operates optimally throughout its lifespan.

5. Warranty and Service Agreements Check the warranty terms provided with the machine. A good warranty, along with service agreements, can give peace of mind and protect your investment.

Conclusion

In conclusion, pipe rust remover machines play a vital role in ensuring the efficiency and safety of various industrial operations. By understanding the importance of rust removal and the benefits of these machines, businesses can make informed decisions that positively impact their operations. When selecting a supplier, taking the time to evaluate their reputation, product range, technological advancements, customer support, and warranty offerings can lead to a successful investment. With the right equipment and partnerships in place, companies can protect their infrastructure from the damaging effects of rust, ultimately fostering a more sustainable and efficient operational environment.