The Importance of Pipe Rust Remover Machine Services

In industrial settings, the maintenance of equipment is crucial for ensuring efficiency and extending the lifespan of machinery. One common problem faced by industries is the buildup of rust on pipes, which can lead to operational inefficiencies and potential hazards. To combat this issue, pipe rust remover machine services have emerged as an essential resource for manufacturers and industrial operations.

Rust, a product of corrosion, forms when iron and oxygen react in the presence of moisture. This process compromises the integrity of pipes, leading to leaks, blockages, and ultimately equipment failure. In various industries—such as manufacturing, oil and gas, and water treatment systems—the presence of rust can disrupt production processes and result in costly downtimes. Therefore, implementing rust removal solutions is not only vital for operational efficiency but also for safety and compliance with industry regulations.

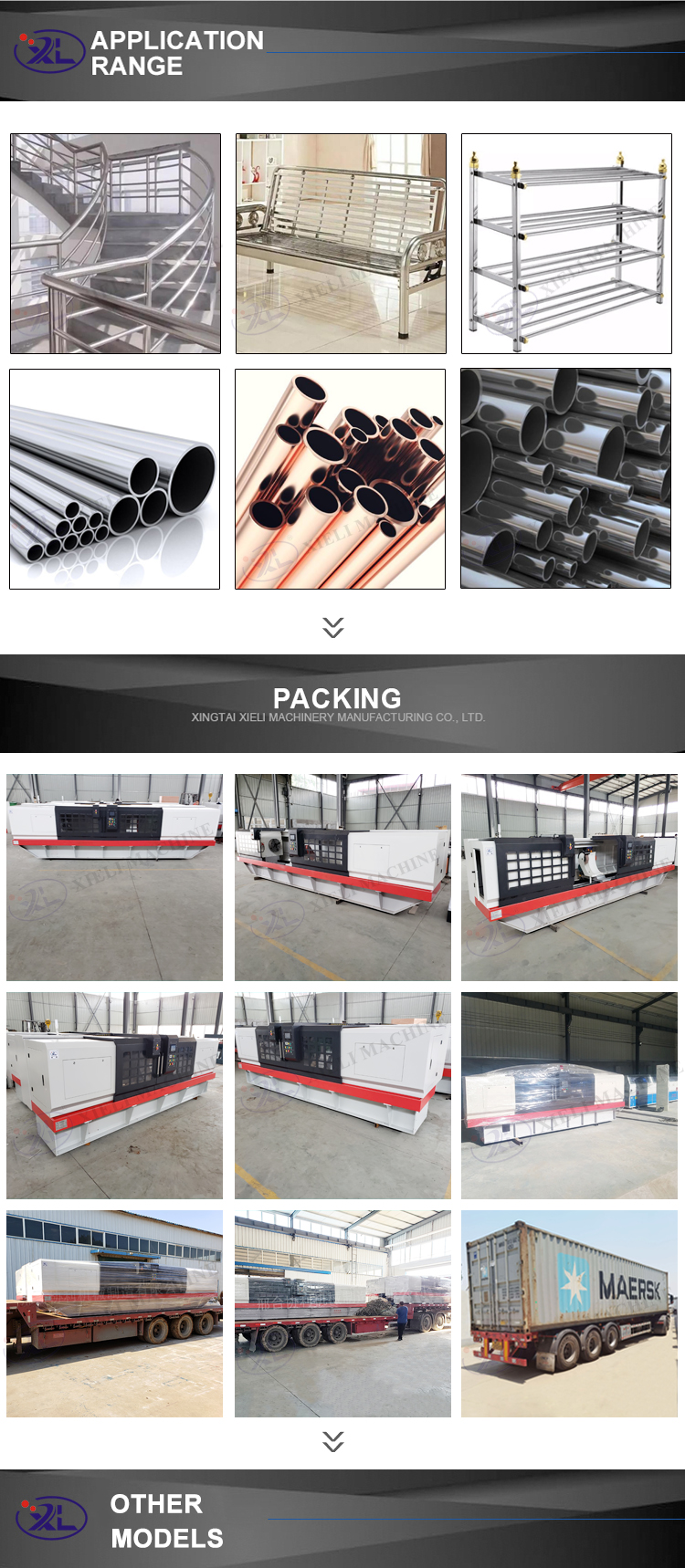

Pipe rust remover machines provide an effective solution to this pervasive issue. These machines utilize advanced technologies, such as abrasive blasting, chemical cleaning, and electrolysis, to eliminate rust from pipes without causing damage to the underlying material. The choice of method often depends on the extent of rust buildup and the specific requirements of the operation.

One of the key benefits of employing pipe rust remover machine services is the ability to restore pipes to their original condition. This process can enhance fluid flow, increase energy efficiency, and reduce the likelihood of leaks. Moreover, regular maintenance through rust removal can significantly prolong the lifespan of piping systems, leading to substantial cost savings over time. Instead of replacing pipes, which can be a significant expense, businesses can opt for rust removal to keep their systems operational.

pipe rust remover machine service

Another advantage of these services is their ability to minimize environmental impact. Rust removal often involves the use of non-toxic chemicals and methods that are environmentally friendly. By choosing specialized services that prioritize sustainability, companies not only enhance their operational efficiency but also fulfill corporate social responsibility commitments.

In addition to cost savings and environmental concerns, safety is a critical factor in the need for pipe rust remover machine services. Rusted pipes can pose serious risks, including structural failures and hazardous leaks, endangering workers and the surrounding environment. Regular rust removal ensures that pipes remain in good condition, reducing the risk of catastrophic failures and promoting workplace safety. Moreover, many jurisdictions have stringent regulations regarding the maintenance of industrial systems, and failing to adhere to these can lead to legal repercussions.

When selecting a pipe rust remover machine service, it is essential to consider the experience and reputation of the service provider. Understanding the technology and methods they utilize can help businesses choose the right partner to meet their specific needs. Additionally, a reputable service provider will often offer guarantees on their work, ensuring that clients receive quality service and results.

In conclusion, pipe rust remover machine services play a vital role in industrial maintenance by preventing rust-related issues that can lead to inefficiency, increased costs, and safety hazards. By investing in these services, industries can restore the functionality of their piping systems, enhance safety, and contribute to environmental sustainability. Ultimately, the choice to prioritize rust removal reflects a commitment to operational excellence and responsibility in today’s competitive industrial landscape. Regular maintenance through specialized rust removal services can safeguard the future of operations, ensuring they run smoothly and efficiently for years to come.