The Rise of Pipe Polishing Machine Suppliers Meeting Industry Demands

In the ever-evolving landscape of manufacturing and metal fabrication, the demand for high-quality finishing processes has surged. Among these, pipe polishing has become an essential operation, ensuring that pipes not only meet aesthetic standards but also comply with regulatory requirements for safety and performance. The growth of pipe polishing machine suppliers is a response to this significant market need, offering a variety of solutions tailored to the diverse needs of different industries.

Understanding Pipe Polishing

Pipe polishing refers to the process of smoothing the surface of pipes, typically made from metals such as stainless steel, aluminum, or carbon steel. This process is crucial for several reasons. Firstly, polished pipes are less prone to corrosion, thereby extending their lifespan and reducing maintenance costs. Secondly, the smooth surfaces enhance the flow of liquids or gases, making them more efficient for various applications, particularly in plumbing, oil and gas, and food processing industries.

The Role of Machine Suppliers

The role of pipe polishing machine suppliers has become increasingly critical as industries seek to optimize their operations. These suppliers offer various types of polishing machines, including manual, semi-automatic, and fully automatic systems. Each type caters to different production volumes and operational efficiencies.

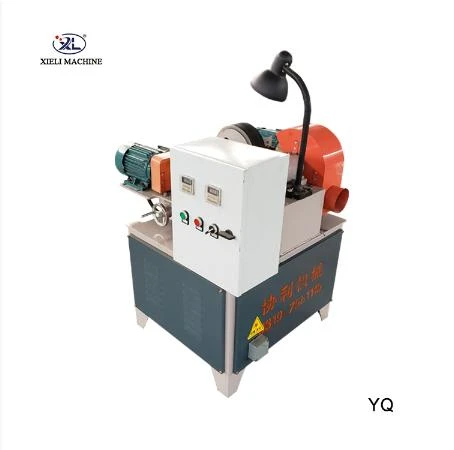

1. Manual Polishing Machines Often favored by small workshops and businesses with lower production demands, these machines are typically easy to operate and require less investment. They allow for a high degree of control and can be ideal for customized, low-volume projects.

2. Semi-Automatic Machines These systems strike a balance between manual and fully automatic machines. They require some human intervention while automating most processes, making them suitable for medium-sized operations that require efficiency without the total loss of manual craftsmanship.

3. Fully Automatic Machines For large-scale operations, fully automatic polishing machines are the go-to option. They are designed for high-throughput production, capable of processing numerous pipes simultaneously with minimal human oversight. Their efficiency translates to lower labor costs and increased productivity.

pipe polishing machine suppliers

Selection Criteria for Machine Suppliers

Choosing the right pipe polishing machine supplier can have a significant impact on operational success. Companies should consider several key factors

1. Quality of Equipment Suppliers should offer high-quality machines that comply with industry standards. This quality assurance not only ensures reliability but also enhances the quality of the polished pipes.

2. Customization Options The ability to customize machinery for specific needs can greatly benefit businesses. Whether it’s adjusting the size or modifying the polishing technique, flexibility can lead to better operational outcomes.

3. After-Sales Support Suppliers that offer robust after-sales support, including maintenance and repair services, instill confidence in their products. This support is crucial for minimizing downtime and ensuring smooth production flows.

4. Customer Testimonials and Case Studies Insights from existing customers can provide invaluable information regarding a supplier's reliability and the performance of their machines.

Conclusion

The landscape of pipe polishing is rapidly advancing, driven by technological innovations and the increasing demand for high-quality finishes in various industries. Pipe polishing machine suppliers are at the forefront of this evolution, providing essential equipment that helps businesses improve efficiency, reduce costs, and enhance product quality. As industries continue to grow and evolve, the role of these suppliers will undoubtedly be pivotal in shaping the future of pipe processing and finishing operations. By selecting the right suppliers, companies can ensure that they remain competitive and meet the ever-growing demands of the market.