Understanding Pipe Polishing Machine Manufacturers Enhancing Metal Finishing

In the realm of metal processing, especially when it comes to pipes, the finish can significantly affect both the aesthetic and functional qualities of the final product. This is where pipe polishing machines come into play. These machines not only enhance the appearance of pipes but also improve their resistance to corrosion and other environmental factors. In this article, we will explore the role of pipe polishing machine manufacturers, the technology behind these machines, and their significance in various industries.

The Importance of Pipe Polishing

Pipes are used across a myriad of industries, from construction and plumbing to oil and gas. The demand for high-quality, polished pipes has grown as industries strive for precision and durability in their projects. A polished pipe surface is not just about visual appeal; it also assists in preventing the accumulation of dirt and debris, making maintenance easier. Furthermore, polished surfaces are less likely to corrode, thus extending the lifespan of the pipes.

The Role of Manufacturers

Pipe polishing machine manufacturers are essential contributors to the metal fabrication industry. They design and produce a variety of machines specifically tailored for the polishing of pipes made from different materials such as stainless steel, aluminum, and more. These manufacturers invest in research and development to innovate and improve their machine designs, ensuring they meet industry standards and client expectations.

When looking for a reputable manufacturer, it is crucial to consider their experience, technology, and customer service. Established companies usually have a proven track record of producing reliable machines. They often provide customization options based on the specific needs of the client, which can include different polishing techniques or machine sizes.

Types of Pipe Polishing Machines

There are various types of pipe polishing machines, each serving different purposes and achieving distinct finishes. Some of the most common types include

1. Rotary Pipe Polishers These machines use a rotating action to polish the pipe surface, providing a smooth finish. They are ideal for achieving a high gloss shine on surfaces that will be prominently displayed.

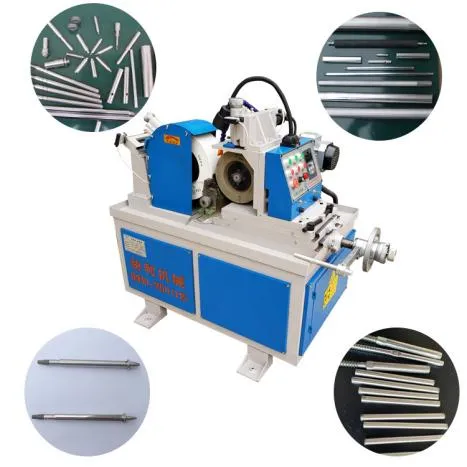

pipe polishing machine manufacturers product

2. Belt Polishers Utilizing abrasive belts, these machines can quickly remove surface imperfections and create a uniform finish. They are suitable for high-volume production environments where efficiency is paramount.

3. Cup Wheel Polishers These machines employ cup wheels fitted with abrasive materials to polish the pipe surfaces. They are particularly effective for removing heavy oxidation and rust, making them ideal for refurbishing old pipes.

Advanced Technology in Pipe Polishing

Modern pipe polishing machines incorporate advanced technologies that enhance their efficiency and effectiveness. Automation has become a key feature, with many machines now equipped with programmable controls that allow for precise adjustments in polishing speed, pressure, and duration. This not only improves the quality of the finish but also minimizes human error.

Moreover, some manufacturers are adopting environmentally friendly practices, such as reducing waste and incorporating energy-efficient components in their designs. As industries shift toward more sustainable practices, these innovations are becoming increasingly important.

Market Trends and Future Directions

The demand for polished pipes is expected to rise as industries continue to grow and evolve. Manufacturers are likely to focus on enhancing the functionality of their machines, potentially incorporating artificial intelligence and machine learning to optimize polishing processes further. The trend towards customization will also continue, as different applications will require specific polishing techniques.

Furthermore, with globalization, manufacturers are expanding their market reach, often collaborating with international suppliers and distributors. This fosters innovation and allows for a diverse array of designs and technologies to be shared and implemented across different regions.

Conclusion

Pipe polishing machine manufacturers play a crucial role in the metal processing industry. By providing advanced machinery that enhances the quality and functionality of pipes, they contribute to the overall efficiency and sustainability of various industries. As technology continues to evolve, so too will the capabilities of these machines, shaping the future of pipe polishing and metal finishing. Investing in high-quality polishing machinery from reputable manufacturers is essential for any business looking to maintain a competitive edge in today’s market.